Call Us

+86-18072289720

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

BTF6H-25.3ZE----BTF6F-50.3GE

Blait

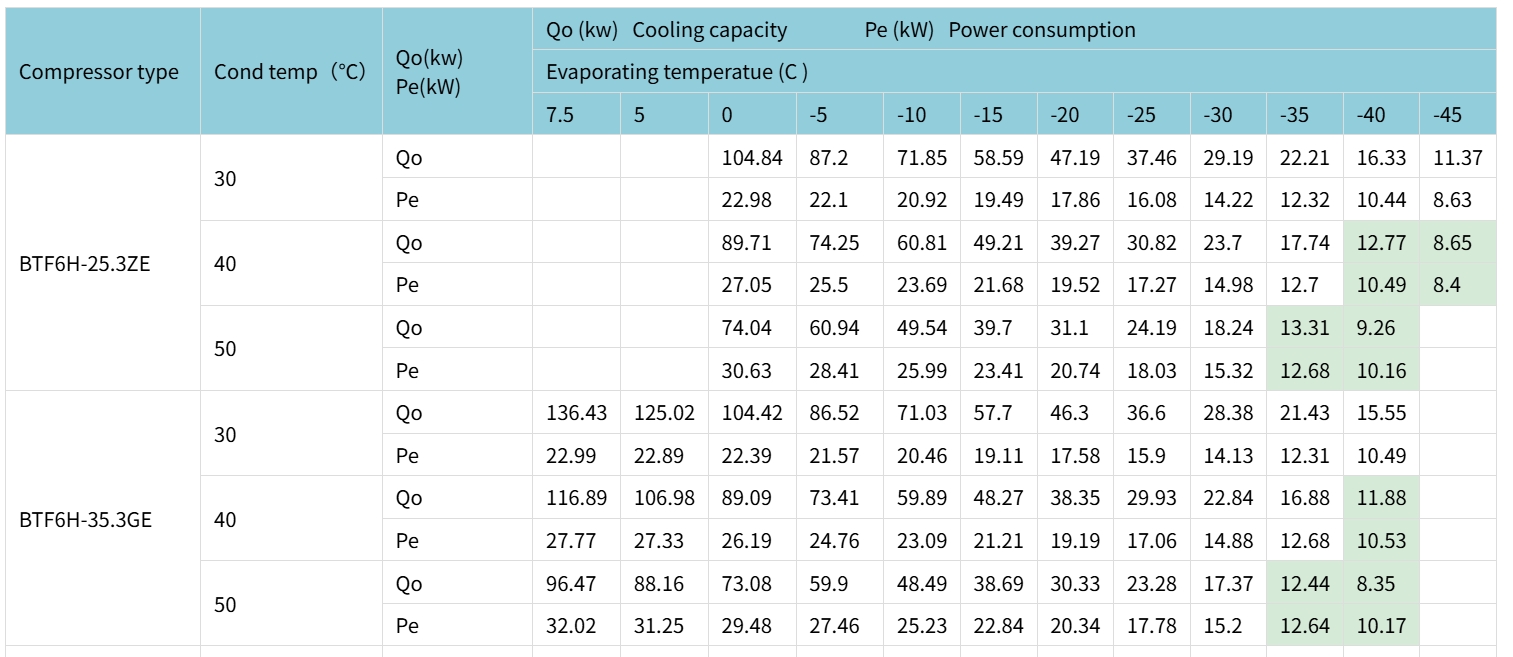

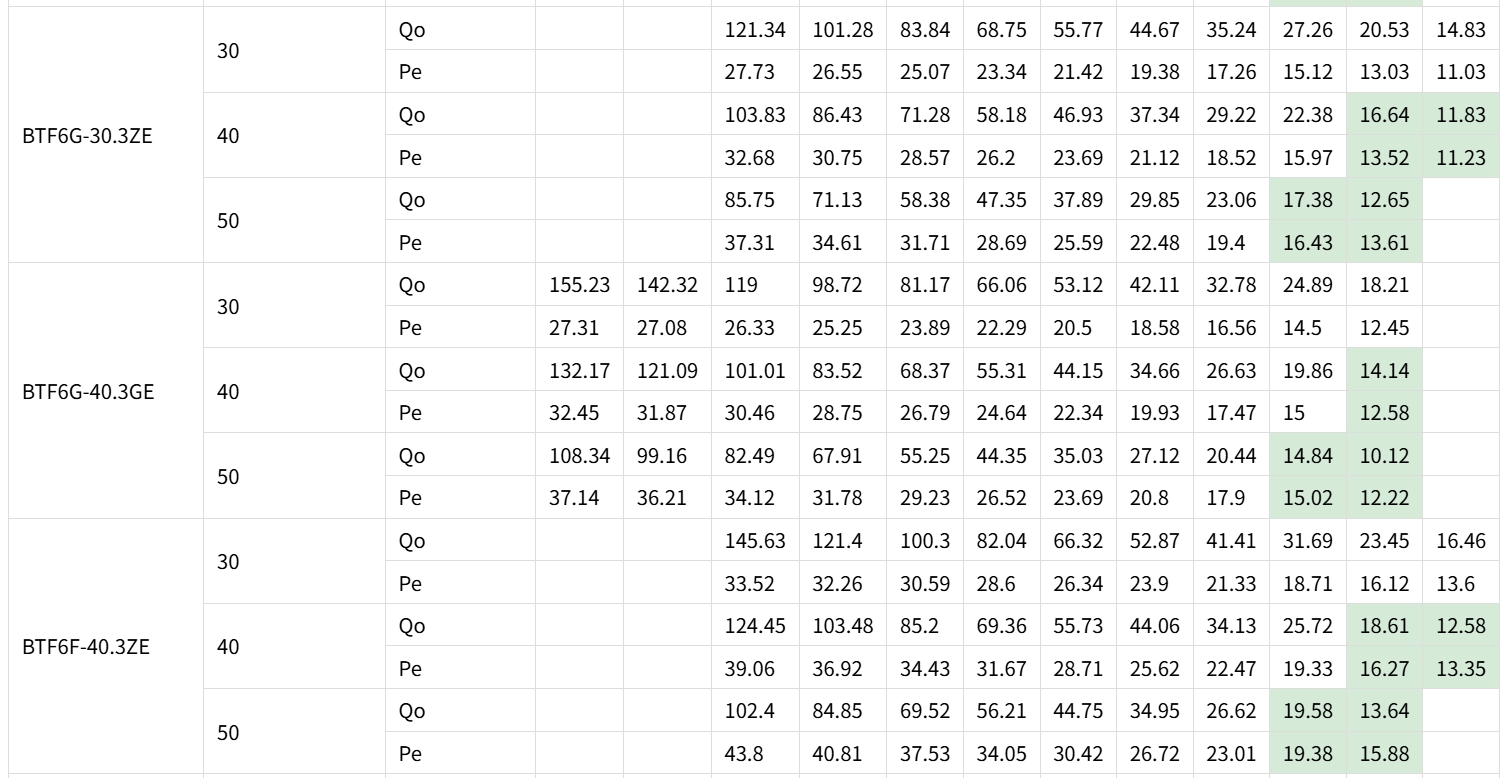

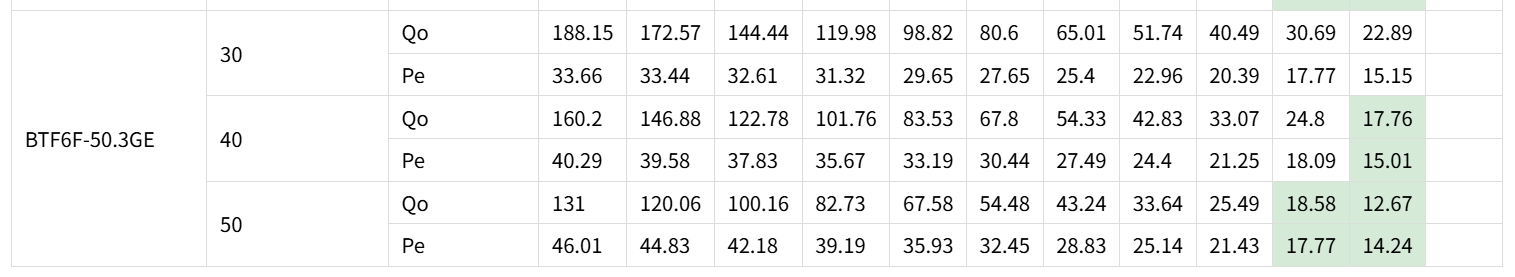

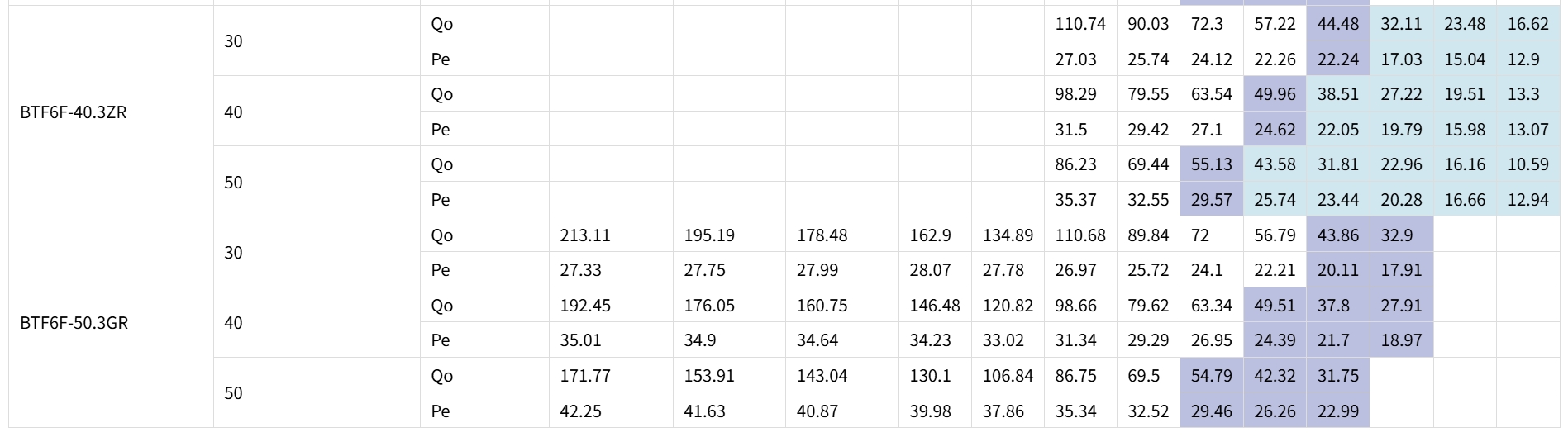

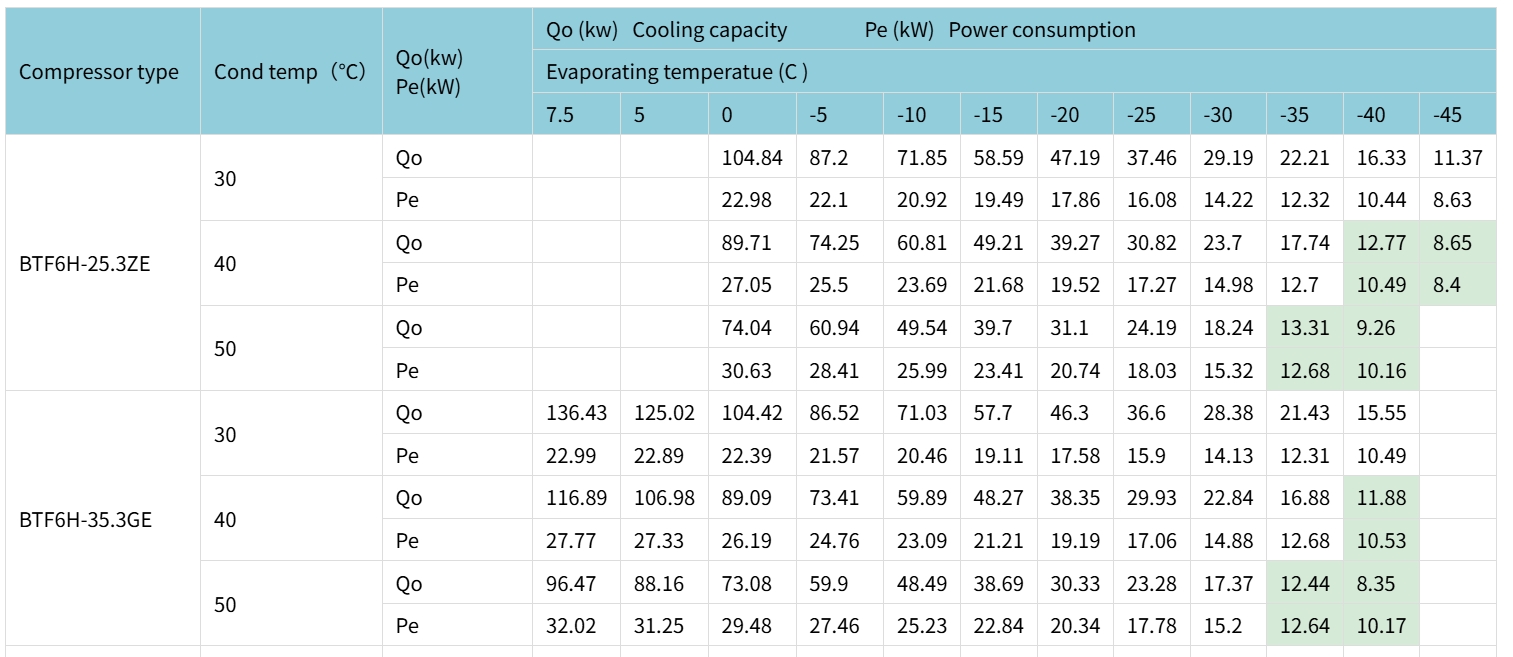

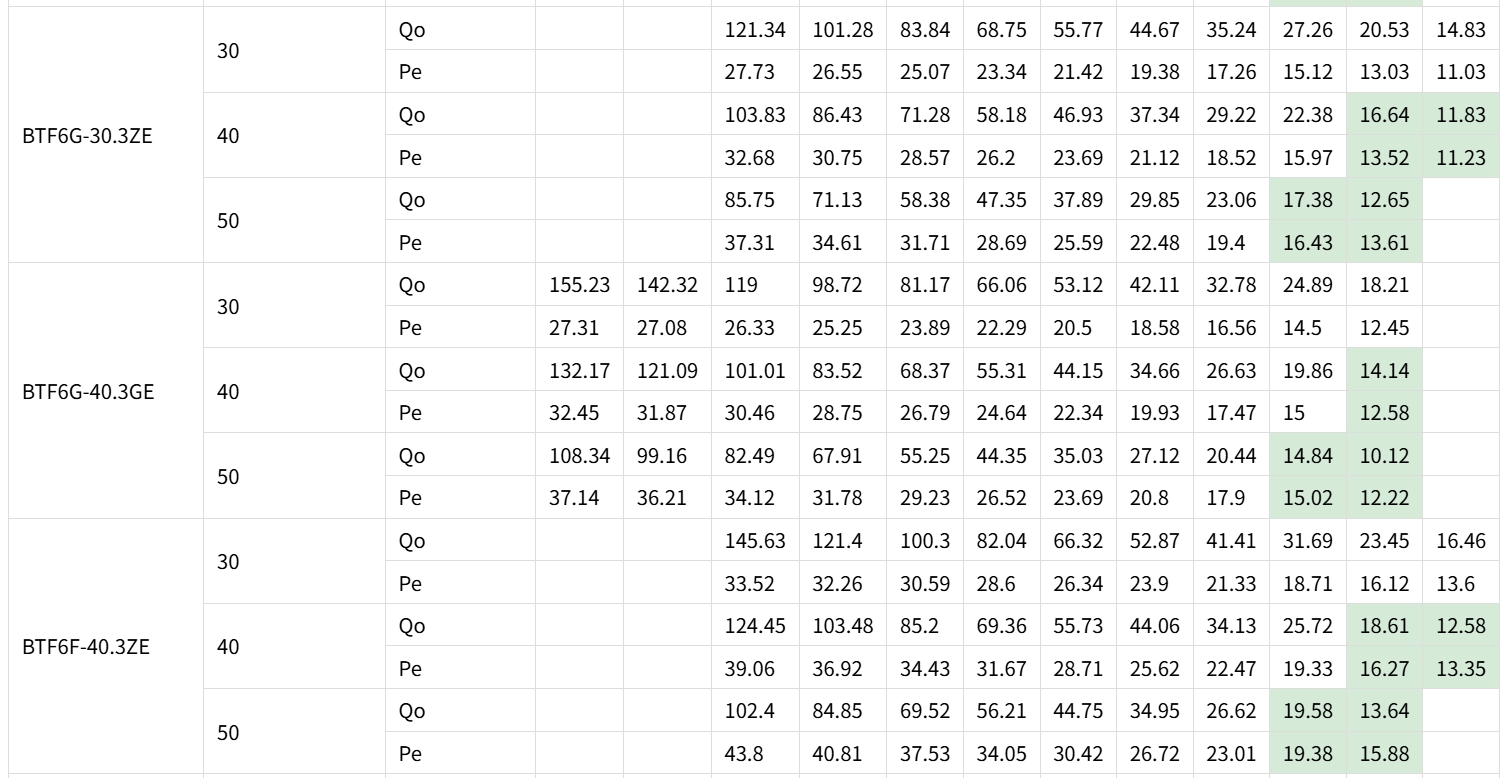

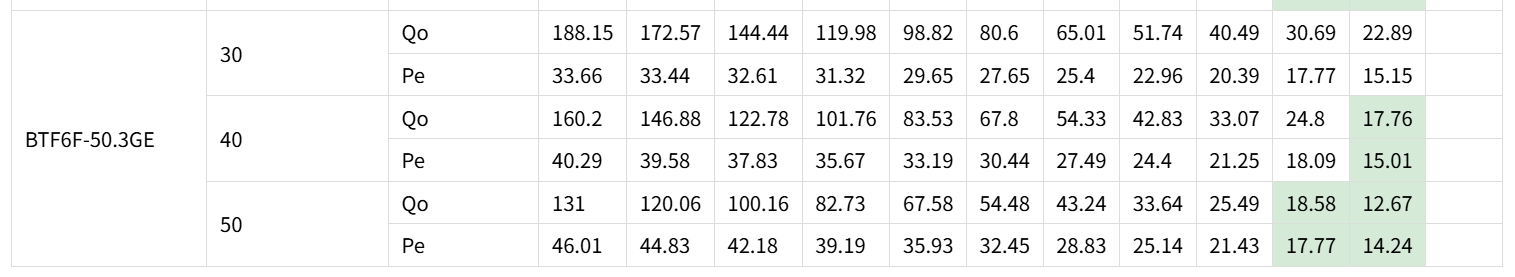

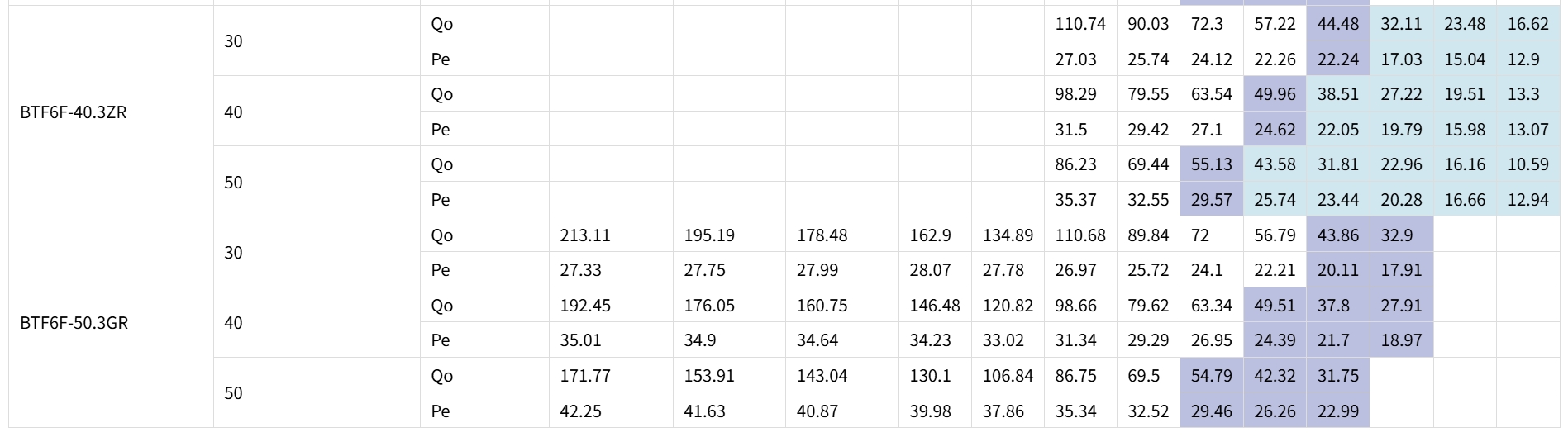

The T Series six-cylinder reciprocating compressors (model range BTF6H-25.3Z to BTF6F-50.3G) are high-performance units designed for industrial refrigeration, large-scale cold storage facilities, and cold chain transportation applications. Supporting multiple refrigerants including R22, R404A, and R507A, these compressors deliver high efficiency, low energy consumption, excellent sealing performance, and adjustable capacity. Applications span commercial freezing, food refrigeration, chemical refrigeration, and natural gas compression.

Features heavy-duty cast iron crankcases and cylinder blocks for enhanced structural stability and vibration resistance, ensuring long-term reliable operation.

Precision-engineered pistons with self-lubricating piston rings (featuring stepped groove design) maintain high compression efficiency throughout the entire lifecycle, reducing energy consumption.

Multiple sets of high-quality piston rod packing seals effectively prevent toxic and corrosive gas leaks, enhancing safety.

Equipped with an adjustable variable clearance head, it flexibly adjusts the compressor's actual displacement according to operating conditions, optimizing energy usage.

Covers single-stage to multi-stage configurations and multi-cylinder combinations for diverse displacement requirements, accommodating operating conditions from 110.5 m³/h to 151.6 m³/h.

Supports multiple refrigerants including R22, R404A, and R507A, widely applied in freezing, refrigeration, cold chain transportation, chemical refrigeration, natural gas compression, and other sectors.

Commercial cold storage and supermarket cold chain systems

Freezing processing and refrigeration facilities

Large-scale food, seafood, and aquatic product processing plants

Chemical and refrigeration engineering projects

Natural gas compression stations and gas recovery systems

Other industrial applications requiring reliable high-flow, high-pressure compressors

Custom-designed units based on compression ratio, flow rate, refrigerant type, etc.;

Selectable interface types (welded flanges, threaded connections, etc.);

Optional auxiliary accessories: oil separators, coolers, inlet filters, noise reduction enclosures, etc.;

On-site layout adaptable to space, vibration, ventilation, and other conditions.

Regularly replace lubricating oil, oil filters, and air filter elements;

Inspect piston rings, valves, and seals for wear based on operating conditions;

Comprehensive inspections recommended every 3–6 months (frequency adjusted per operating environment and load);

Ensure adequate heat dissipation and ventilation for compressors; avoid operation in high-temperature environments.

The T Series six-cylinder reciprocating compressors (model range BTF6H-25.3Z to BTF6F-50.3G) are high-performance units designed for industrial refrigeration, large-scale cold storage facilities, and cold chain transportation applications. Supporting multiple refrigerants including R22, R404A, and R507A, these compressors deliver high efficiency, low energy consumption, excellent sealing performance, and adjustable capacity. Applications span commercial freezing, food refrigeration, chemical refrigeration, and natural gas compression.

Features heavy-duty cast iron crankcases and cylinder blocks for enhanced structural stability and vibration resistance, ensuring long-term reliable operation.

Precision-engineered pistons with self-lubricating piston rings (featuring stepped groove design) maintain high compression efficiency throughout the entire lifecycle, reducing energy consumption.

Multiple sets of high-quality piston rod packing seals effectively prevent toxic and corrosive gas leaks, enhancing safety.

Equipped with an adjustable variable clearance head, it flexibly adjusts the compressor's actual displacement according to operating conditions, optimizing energy usage.

Covers single-stage to multi-stage configurations and multi-cylinder combinations for diverse displacement requirements, accommodating operating conditions from 110.5 m³/h to 151.6 m³/h.

Supports multiple refrigerants including R22, R404A, and R507A, widely applied in freezing, refrigeration, cold chain transportation, chemical refrigeration, natural gas compression, and other sectors.

Commercial cold storage and supermarket cold chain systems

Freezing processing and refrigeration facilities

Large-scale food, seafood, and aquatic product processing plants

Chemical and refrigeration engineering projects

Natural gas compression stations and gas recovery systems

Other industrial applications requiring reliable high-flow, high-pressure compressors

Custom-designed units based on compression ratio, flow rate, refrigerant type, etc.;

Selectable interface types (welded flanges, threaded connections, etc.);

Optional auxiliary accessories: oil separators, coolers, inlet filters, noise reduction enclosures, etc.;

On-site layout adaptable to space, vibration, ventilation, and other conditions.

Regularly replace lubricating oil, oil filters, and air filter elements;

Inspect piston rings, valves, and seals for wear based on operating conditions;

Comprehensive inspections recommended every 3–6 months (frequency adjusted per operating environment and load);

Ensure adequate heat dissipation and ventilation for compressors; avoid operation in high-temperature environments.

No products found