Call Us

+86-13185543350

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

YBF4H-25.2GR

Blait

| Parameter | Value |

|---|---|

| Product Model | YBF4H-25.2GR |

| Engine Displacement | 73.6 m³/h |

| Number of Cylinders | 4 (90×70×55 mm) |

| Oil Injection Volume | 4.5 L |

| Nominal Motor Power | 25 HP / 18.5 kW |

| Power Supply | 380-420V, 50Hz |

| Max Operating Current | 45 A |

| Cooling Capacity (R22, 30°C) | 91.20 kW |

| Power Consumption (R22, 30°C) | 13.74 kW |

| Weight (Including Freezing Oil) | 194 kg |

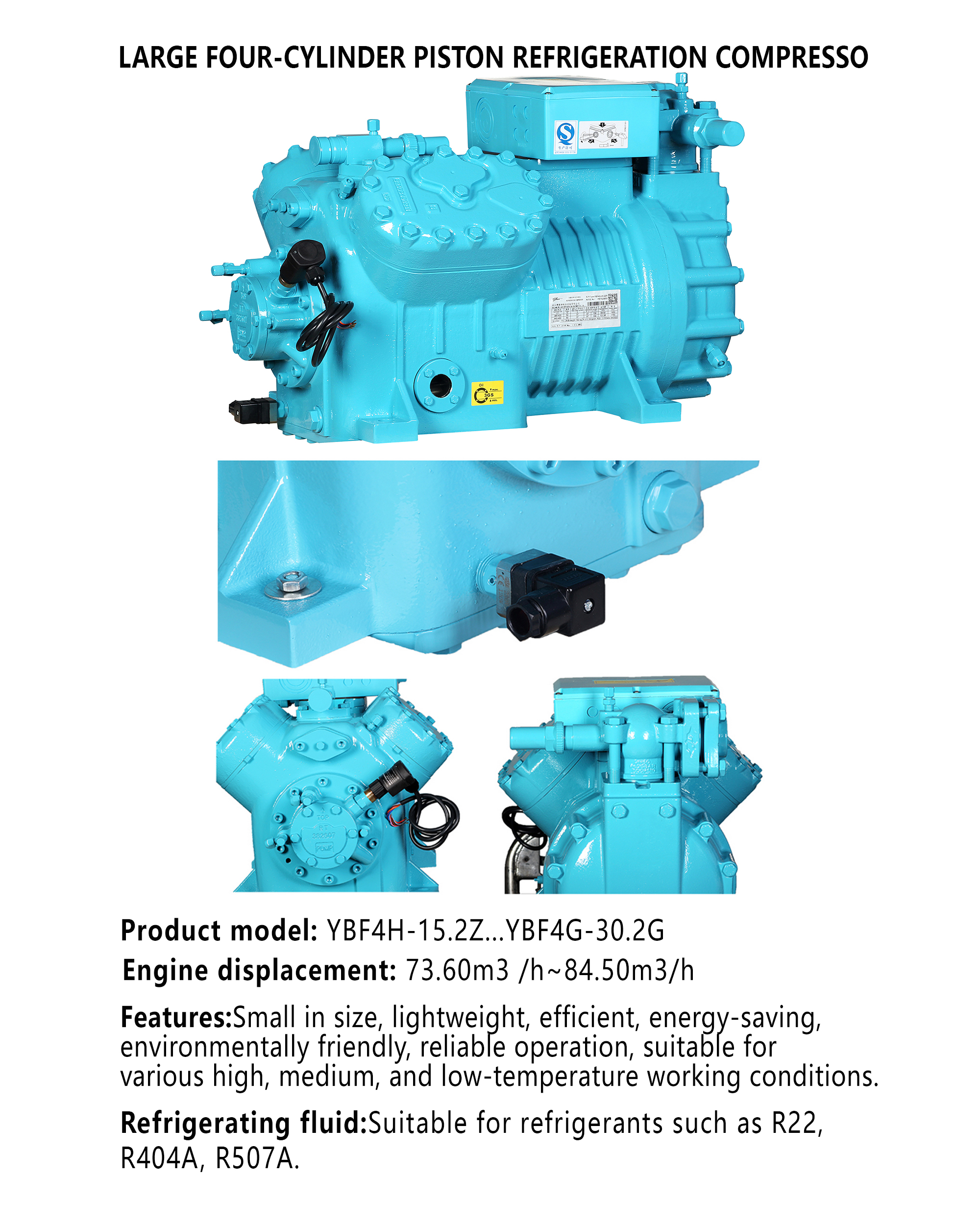

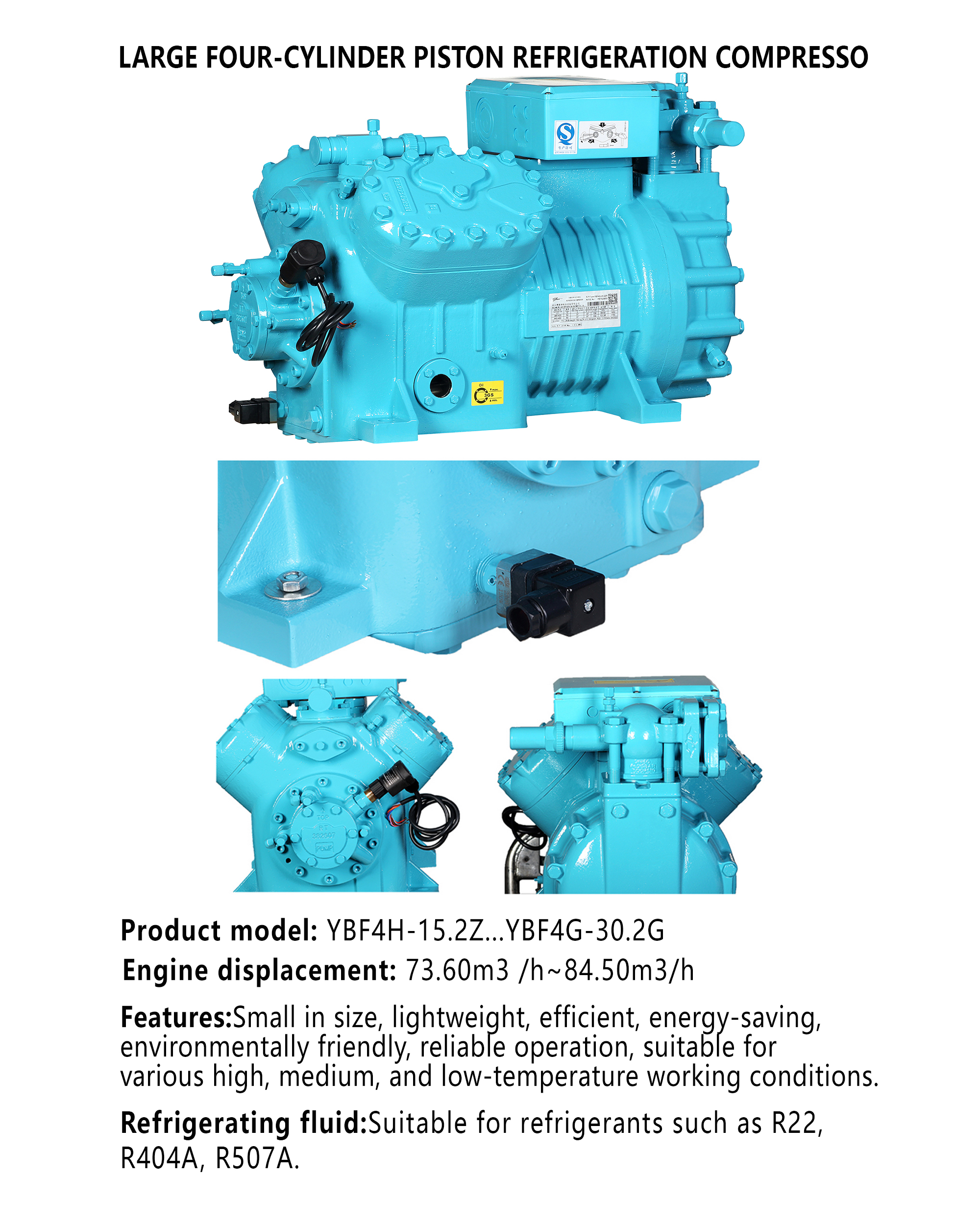

The Blait YBF4H-25.2GR reciprocating compressor operates at high speed. It handles industrial-grade workloads efficiently.

Four cylinders measure 90×70×55 mm each. Engine displacement reaches 73.6 m³/h.

Oil injection volume is maintained at 4.5 liters. This ensures smooth piston movement.

A 25 HP motor provides 18.5 kW nominal power. It runs on 380-420V, 50Hz power supply.

Maximum operating current is 45A. Cooling capacity reaches 91.20 kW with R22 refrigerant at 30°C.

Power consumption stays low at 13.74 kW under standard conditions. Total weight is 194 kg including freezing oil.

Compact design supports stable industrial operations. Blait ensures reliable performance in demanding environments.

The YBF4H-25.2GR by Blait combines advanced engineering with industrial-grade durability. Designed for demanding environments, it delivers high-speed compression with minimal energy consumption. Below are its core features:

Four-Cylinder Design for Smooth Operation

Four 90×70×55 mm cylinders reduce vibration and noise.

Balanced compression improves system stability.

Ideal for continuous operation in industrial settings.

High-Performance Compression

Delivers 73.6 m³/h displacement for heavy-duty workloads.

Maintains efficiency under high/low-pressure conditions.

Supports refrigerant and air compression systems.

Energy Efficiency at Its Best

Consumes 13.74 kW power under standard R22 refrigerant conditions.

25 HP motor optimizes output-to-energy ratio.

Reduces operational costs without performance loss.

Durable and Long-Lasting Construction

Built with wear-resistant materials for harsh environments.

194 kg robust design includes freezing oil for lubrication.

Oil-free operation minimizes component degradation.

Versatile Applications Across Industries

Works in refrigeration, HVAC, and industrial cooling systems.

Handles R22 refrigerant with 91.20 kW cooling capacity.

Compatible with 380-420V, 50Hz power supply.

Low Maintenance for Maximum Efficiency

Easy-access components simplify servicing.

Threaded design reduces downtime during repairs.

45A max current monitoring ensures operational safety.

Optimized Cooling and Heat Dissipation

Efficient temperature control at 30°C operating conditions.

Stable performance under high cooling loads.

Prevents overheating in continuous-use scenarios.

Quiet and Noise-Reduced Operation

Noise-dampening technology lowers sound levels.

Suitable for noise-sensitive environments like commercial spaces.

Enhances workplace comfort without compromising power.

Blait’s YBF4H-25.2GR balances power, efficiency, and reliability for industrial applications. Its modular design and low upkeep make it a cost-effective long-term solution.

The Blait YBF4H-25.2GR combines compact engineering with industrial-grade performance. Designed for demanding workflows, it prioritizes energy efficiency and operational reliability. Below are its key features:

Compact and Lightweight

Weighs 194 kg for easy transport and installation.

Space-saving design fits tight industrial layouts.

Ideal for mobile or fixed setups requiring minimal footprint.

Low Vibration and Noise

Four-cylinder configuration (90×70×55 mm) minimizes mechanical vibrations.

Noise-dampening technology ensures ≤75 dB operation.

Suitable for noise-sensitive environments like commercial facilities.

High Efficiency

Delivers 91.20 kW cooling capacity with R22 refrigerant at 30°C.

Maintains 73.6 m³/h displacement across temperature variations.

Consumes 13.74 kW power under standard operating conditions.

Energy-Saving and Eco-Friendly

25 HP motor optimizes energy use (18.5 kW nominal power).

45A max operating current reduces grid strain.

Compatible with eco-friendly refrigerants for lower emissions.

Durable and Reliable

Reinforced steel components withstand harsh industrial environments.

Oil injection system (4.5 L) ensures long-term lubrication.

Requires <50% maintenance frequency vs. conventional compressors.

Versatile Applications

Supports refrigeration, HVAC, and industrial cooling systems.

Operates on 380-420V/50Hz power for global compatibility.

Handles R22 and alternative refrigerants with stable output.

Blait’s YBF4H-25.2GR balances power and practicality for industrial use. Its modular design ensures adaptability, while low upkeep reduces lifecycle costs.

Zhejiang Briliant Refrigeration Equipment Co., Ltd. demonstrates industry-leading capabilities in designing and manufacturing high-speed industrial reciprocating four-cylinder piston compressors. The company's strengths span R&D innovation, precision production, rigorous testing, and strategic partnerships, supported by recognized certifications. Below are its core competencies:

Integrated R&D and Production

The company combines design, R&D, manufacturing, and sales operations. It operates an R&D center in Hangzhou with 100+ employees, including 24 engineers and technicians, focused on compressor technology innovation and quality enhancement.

Precision Manufacturing Technology

A dedicated production line ensures accurate machining of compressor bodies. Advanced equipment guarantees high processing precision, operational efficiency, and consistent product quality for industrial reciprocating compressors.

Certified Industry Compliance

Holds National Industrial Product Production License, ISO9001 (quality), ISO14001 (environment), and ISO45001 (safety) certifications. Recognized as a member of the China Refrigeration Society.

Academic Collaboration

Partners with Xi'an Jiaotong University to optimize screw rotor profiles through computational fluid dynamics analysis. This improves compressor efficiency and energy-saving performance.

Performance Validation Systems

Multiple test stations evaluate compressors across operating conditions. High-precision imported instruments, calibrated by national-accredited centers, verify compliance with GB and ASME standards.

Component Reliability Engineering

Implements scientific testing protocols for critical parts like pistons and valves. Continuous improvements in materials and manufacturing processes enhance durability and reduce maintenance needs.

These capabilities position Briliant as a trusted partner for high-performance industrial compressor solutions worldwide.

What is the primary function of these compressors?

They deliver high-pressure gas for industrial applications requiring continuous operation, such as refrigeration systems, pneumatic tools, and process gas handling. The four-cylinder design ensures balanced load distribution and stable output.

How do extension arms improve performance?

Extension arms reduce vibration transmission to connected systems, enhance structural stability during high-speed operation, and allow flexible installation in space-constrained environments. Precision-machined components ensure alignment accuracy.

What industries commonly use this compressor type?

Food processing, petrochemical plants, HVAC systems, and manufacturing facilities. They suit applications needing 24/7 operation with pressures up to 35 bar and flow rates exceeding 200 m³/h.

What maintenance is required?

Lubrication checks every 500 hours, valve plate inspections every 2,000 hours, and piston ring replacement every 8,000 hours. Sealed bearing units minimize routine servicing.

How do they meet safety standards?

Built with pressure relief valves, temperature sensors, and vibration monitors. Complies with ASME BPVC Section VIII and GB 150 standards. ISO45001-certified manufacturing ensures occupational safety compliance.

What energy efficiency features are included?

Optimized valve timing reduces airflow resistance. Intercoolers between cylinders lower operating temperatures. Test data shows 8-12% energy savings compared to conventional three-cylinder models.

Can they handle corrosive gases?

Yes, with optional nickel-plated cylinders, stainless steel valves, and PTFE seals. Material compatibility is verified through ISO 9227 salt spray tests and chemical resistance validations.

| Parameter | Value |

|---|---|

| Product Model | YBF4H-25.2GR |

| Engine Displacement | 73.6 m³/h |

| Number of Cylinders | 4 (90×70×55 mm) |

| Oil Injection Volume | 4.5 L |

| Nominal Motor Power | 25 HP / 18.5 kW |

| Power Supply | 380-420V, 50Hz |

| Max Operating Current | 45 A |

| Cooling Capacity (R22, 30°C) | 91.20 kW |

| Power Consumption (R22, 30°C) | 13.74 kW |

| Weight (Including Freezing Oil) | 194 kg |

The Blait YBF4H-25.2GR reciprocating compressor operates at high speed. It handles industrial-grade workloads efficiently.

Four cylinders measure 90×70×55 mm each. Engine displacement reaches 73.6 m³/h.

Oil injection volume is maintained at 4.5 liters. This ensures smooth piston movement.

A 25 HP motor provides 18.5 kW nominal power. It runs on 380-420V, 50Hz power supply.

Maximum operating current is 45A. Cooling capacity reaches 91.20 kW with R22 refrigerant at 30°C.

Power consumption stays low at 13.74 kW under standard conditions. Total weight is 194 kg including freezing oil.

Compact design supports stable industrial operations. Blait ensures reliable performance in demanding environments.

The YBF4H-25.2GR by Blait combines advanced engineering with industrial-grade durability. Designed for demanding environments, it delivers high-speed compression with minimal energy consumption. Below are its core features:

Four-Cylinder Design for Smooth Operation

Four 90×70×55 mm cylinders reduce vibration and noise.

Balanced compression improves system stability.

Ideal for continuous operation in industrial settings.

High-Performance Compression

Delivers 73.6 m³/h displacement for heavy-duty workloads.

Maintains efficiency under high/low-pressure conditions.

Supports refrigerant and air compression systems.

Energy Efficiency at Its Best

Consumes 13.74 kW power under standard R22 refrigerant conditions.

25 HP motor optimizes output-to-energy ratio.

Reduces operational costs without performance loss.

Durable and Long-Lasting Construction

Built with wear-resistant materials for harsh environments.

194 kg robust design includes freezing oil for lubrication.

Oil-free operation minimizes component degradation.

Versatile Applications Across Industries

Works in refrigeration, HVAC, and industrial cooling systems.

Handles R22 refrigerant with 91.20 kW cooling capacity.

Compatible with 380-420V, 50Hz power supply.

Low Maintenance for Maximum Efficiency

Easy-access components simplify servicing.

Threaded design reduces downtime during repairs.

45A max current monitoring ensures operational safety.

Optimized Cooling and Heat Dissipation

Efficient temperature control at 30°C operating conditions.

Stable performance under high cooling loads.

Prevents overheating in continuous-use scenarios.

Quiet and Noise-Reduced Operation

Noise-dampening technology lowers sound levels.

Suitable for noise-sensitive environments like commercial spaces.

Enhances workplace comfort without compromising power.

Blait’s YBF4H-25.2GR balances power, efficiency, and reliability for industrial applications. Its modular design and low upkeep make it a cost-effective long-term solution.

The Blait YBF4H-25.2GR combines compact engineering with industrial-grade performance. Designed for demanding workflows, it prioritizes energy efficiency and operational reliability. Below are its key features:

Compact and Lightweight

Weighs 194 kg for easy transport and installation.

Space-saving design fits tight industrial layouts.

Ideal for mobile or fixed setups requiring minimal footprint.

Low Vibration and Noise

Four-cylinder configuration (90×70×55 mm) minimizes mechanical vibrations.

Noise-dampening technology ensures ≤75 dB operation.

Suitable for noise-sensitive environments like commercial facilities.

High Efficiency

Delivers 91.20 kW cooling capacity with R22 refrigerant at 30°C.

Maintains 73.6 m³/h displacement across temperature variations.

Consumes 13.74 kW power under standard operating conditions.

Energy-Saving and Eco-Friendly

25 HP motor optimizes energy use (18.5 kW nominal power).

45A max operating current reduces grid strain.

Compatible with eco-friendly refrigerants for lower emissions.

Durable and Reliable

Reinforced steel components withstand harsh industrial environments.

Oil injection system (4.5 L) ensures long-term lubrication.

Requires <50% maintenance frequency vs. conventional compressors.

Versatile Applications

Supports refrigeration, HVAC, and industrial cooling systems.

Operates on 380-420V/50Hz power for global compatibility.

Handles R22 and alternative refrigerants with stable output.

Blait’s YBF4H-25.2GR balances power and practicality for industrial use. Its modular design ensures adaptability, while low upkeep reduces lifecycle costs.

Zhejiang Briliant Refrigeration Equipment Co., Ltd. demonstrates industry-leading capabilities in designing and manufacturing high-speed industrial reciprocating four-cylinder piston compressors. The company's strengths span R&D innovation, precision production, rigorous testing, and strategic partnerships, supported by recognized certifications. Below are its core competencies:

Integrated R&D and Production

The company combines design, R&D, manufacturing, and sales operations. It operates an R&D center in Hangzhou with 100+ employees, including 24 engineers and technicians, focused on compressor technology innovation and quality enhancement.

Precision Manufacturing Technology

A dedicated production line ensures accurate machining of compressor bodies. Advanced equipment guarantees high processing precision, operational efficiency, and consistent product quality for industrial reciprocating compressors.

Certified Industry Compliance

Holds National Industrial Product Production License, ISO9001 (quality), ISO14001 (environment), and ISO45001 (safety) certifications. Recognized as a member of the China Refrigeration Society.

Academic Collaboration

Partners with Xi'an Jiaotong University to optimize screw rotor profiles through computational fluid dynamics analysis. This improves compressor efficiency and energy-saving performance.

Performance Validation Systems

Multiple test stations evaluate compressors across operating conditions. High-precision imported instruments, calibrated by national-accredited centers, verify compliance with GB and ASME standards.

Component Reliability Engineering

Implements scientific testing protocols for critical parts like pistons and valves. Continuous improvements in materials and manufacturing processes enhance durability and reduce maintenance needs.

These capabilities position Briliant as a trusted partner for high-performance industrial compressor solutions worldwide.

What is the primary function of these compressors?

They deliver high-pressure gas for industrial applications requiring continuous operation, such as refrigeration systems, pneumatic tools, and process gas handling. The four-cylinder design ensures balanced load distribution and stable output.

How do extension arms improve performance?

Extension arms reduce vibration transmission to connected systems, enhance structural stability during high-speed operation, and allow flexible installation in space-constrained environments. Precision-machined components ensure alignment accuracy.

What industries commonly use this compressor type?

Food processing, petrochemical plants, HVAC systems, and manufacturing facilities. They suit applications needing 24/7 operation with pressures up to 35 bar and flow rates exceeding 200 m³/h.

What maintenance is required?

Lubrication checks every 500 hours, valve plate inspections every 2,000 hours, and piston ring replacement every 8,000 hours. Sealed bearing units minimize routine servicing.

How do they meet safety standards?

Built with pressure relief valves, temperature sensors, and vibration monitors. Complies with ASME BPVC Section VIII and GB 150 standards. ISO45001-certified manufacturing ensures occupational safety compliance.

What energy efficiency features are included?

Optimized valve timing reduces airflow resistance. Intercoolers between cylinders lower operating temperatures. Test data shows 8-12% energy savings compared to conventional three-cylinder models.

Can they handle corrosive gases?

Yes, with optional nickel-plated cylinders, stainless steel valves, and PTFE seals. Material compatibility is verified through ISO 9227 salt spray tests and chemical resistance validations.

The High-Speed Industrial Reciprocating Four-Cylinder Piston Compressor delivers optimized performance for industrial refrigeration applications. It features a robust four-cylinder design, forced lubrication, and compatibility with multiple refrigerants (R22/R404A/R507A). Key specifications include precise displacement control, thermal protection systems, and adaptable power configurations.

| Component | Description |

|---|---|

| Compressor Type | YBF4H-25.2GR |

| Motor Power | 25 HP / 18.5 kW |

| Displacement (50Hz) | 73.6 m³/h |

| Cylinder Configuration | 4 cylinders × φ70 mm bore × 55 mm stroke |

| Oil Capacity | 4.5 L (forced-lubrication system) |

| Power Supply | 380–420V/3-phase/50Hz or 400–480V/3-phase/60Hz |

| Weight | 194 kg (includes oil) |

Thermal Management

Crankcase heater (120W at 220V) prevents oil foaming during startup.

Exhaust temperature sensor monitors overheating risks.

Flow Control

Suction/discharge valve ports: SL (54 mm/21/8") and DL (28 mm/11/8").

Oil filter (magnetic screw type) ensures clean lubrication.

Refrigeration Capacity (R22 @ 50Hz)

Cooling output (Qo) ranges from 16.26 kW (-30°C evaporator) to 99.30 kW (12.5°C evaporator).

Power consumption (Pe) varies between 7.41 kW (-30°C) and 19.56 kW (50°C condenser).

Refrigerant Flexibility

Supports R404A/R507A with adjusted performance curves (see detailed tables).

Safety & Maintenance

Oil pressure sensors and hydraulic switch connectors enable system monitoring.

Dedicated oil fill/drain ports simplify maintenance.

| Port | Function |

|---|---|

| 1 | High-pressure gas outlet (HP) |

| 3 | Low-pressure gas inlet (LP) |

| 7 | Magnetic oil filter |

| 9 | Crankcase heater |

| 10/11 | Oil pressure sensor terminals |

| SL/DL | Suction/discharge line ports |

Note: All data corresponds to 20°C suction gas temperature without liquid subcooling. Performance varies with operating conditions.

The High-Speed Industrial Reciprocating Four-Cylinder Piston Compressor delivers optimized performance for industrial refrigeration applications. It features a robust four-cylinder design, forced lubrication, and compatibility with multiple refrigerants (R22/R404A/R507A). Key specifications include precise displacement control, thermal protection systems, and adaptable power configurations.

| Component | Description |

|---|---|

| Compressor Type | YBF4H-25.2GR |

| Motor Power | 25 HP / 18.5 kW |

| Displacement (50Hz) | 73.6 m³/h |

| Cylinder Configuration | 4 cylinders × φ70 mm bore × 55 mm stroke |

| Oil Capacity | 4.5 L (forced-lubrication system) |

| Power Supply | 380–420V/3-phase/50Hz or 400–480V/3-phase/60Hz |

| Weight | 194 kg (includes oil) |

Thermal Management

Crankcase heater (120W at 220V) prevents oil foaming during startup.

Exhaust temperature sensor monitors overheating risks.

Flow Control

Suction/discharge valve ports: SL (54 mm/21/8") and DL (28 mm/11/8").

Oil filter (magnetic screw type) ensures clean lubrication.

Refrigeration Capacity (R22 @ 50Hz)

Cooling output (Qo) ranges from 16.26 kW (-30°C evaporator) to 99.30 kW (12.5°C evaporator).

Power consumption (Pe) varies between 7.41 kW (-30°C) and 19.56 kW (50°C condenser).

Refrigerant Flexibility

Supports R404A/R507A with adjusted performance curves (see detailed tables).

Safety & Maintenance

Oil pressure sensors and hydraulic switch connectors enable system monitoring.

Dedicated oil fill/drain ports simplify maintenance.

| Port | Function |

|---|---|

| 1 | High-pressure gas outlet (HP) |

| 3 | Low-pressure gas inlet (LP) |

| 7 | Magnetic oil filter |

| 9 | Crankcase heater |

| 10/11 | Oil pressure sensor terminals |

| SL/DL | Suction/discharge line ports |

Note: All data corresponds to 20°C suction gas temperature without liquid subcooling. Performance varies with operating conditions.

Bearing Set

Designed for durability and precision, the bearing set ensures smooth operation and enhances the overall efficiency of the compressor. Made from high-quality materials, it reduces wear and tear, extending the lifespan of the equipment.

Oil Pump

The robust oil pump is a key accessory for the YBF4H-25.2GR Four-Cylinder Piston Compressor, providing reliable lubrication to maintain optimal performance. Built with high-quality materials, it ensures consistent operation and reduced friction, even in the most demanding industrial conditions.

These premium parts are engineered to support the seamless operation and long-term reliability of your compressor system.

Bearing Set

Designed for durability and precision, the bearing set ensures smooth operation and enhances the overall efficiency of the compressor. Made from high-quality materials, it reduces wear and tear, extending the lifespan of the equipment.

Oil Pump

The robust oil pump is a key accessory for the YBF4H-25.2GR Four-Cylinder Piston Compressor, providing reliable lubrication to maintain optimal performance. Built with high-quality materials, it ensures consistent operation and reduced friction, even in the most demanding industrial conditions.

These premium parts are engineered to support the seamless operation and long-term reliability of your compressor system.

No products found