Call Us

+86-18072289720

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Two Stage Screw Refrigeration Compressor

Blait

Blait’s Two Stage Screw Refrigeration Compressor (YLG Series) is an energy-saving powerhouse designed for heavy-duty industrial cooling and freezing systems. Featuring a semi-hermetic structure, variable speed drive (VSD) technology, and dual cooling options (air-cooled/water-cooled), this screw compressor delivers exceptional efficiency, durability, and operational flexibility. With a power range of 4 kW to 355 kW and displacement of 0.8-1.2 m³/min, it caters to diverse industrial needs—from large-scale cold storage to high-demand freezing lines. The advanced YZ57 screw rotor profile minimizes energy loss, making it a cost-effective and eco-friendly choice for modern industrial facilities.

Adopting the patented YZ57 tooth profile (composed of arcs and higher-order curves), the compressor boasts a high area utilization coefficient (0.41 & 0.45) and reduced leakage triangle area, maximizing compression efficiency and minimizing energy waste.

Equipped with advanced VSD, the compressor automatically adjusts motor speed based on real-time air demand, reducing energy consumption by over 30% compared to fixed-speed models. This technology also extends the machine’s lifespan by reducing wear during startup and low-load operation.

Offering both air-cooling and water-cooling options, the compressor adapts to different industrial environments. Its mobile installation design allows flexible placement, simplifying on-site setup and maintenance.

The semi-hermetic structure enhances durability and reduces refrigerant leakage, while the oil-free design ensures clean compressed air—ideal for industries with strict hygiene requirements. The 12-liter lubricant capacity and built-in oil flow monitoring system guarantee reliable lubrication.

A user-friendly control system enables real-time monitoring of temperature, pressure, and energy consumption, allowing operators to optimize settings and prevent downtime. The built-in energy recovery system captures up to 70% of waste energy from the oil circuit and motor, reusing it for heating or other industrial processes.

Withstands pressure differences of up to 2.0 MPa, featuring a standard PTC110°C temperature sensor and INT69 FSY protection module for safe operation under extreme conditions.

Blait is a leading provider of advanced screw compressors in China, with core advantages that set us apart:

Technological leadership in screw rotor design, developed through rigorous R&D and partnerships with industry experts.

ISO9001-certified manufacturing processes, using high-quality materials and precision machining to ensure product reliability.

Versatile product range (YLG20Z-84 ~ YLG30Z-118) to match specific cooling capacity and pressure requirements.

Energy recovery technology that cuts operational costs and supports sustainability goals.

Customizable OEM solutions and responsive technical support, tailored to your industrial needs.

Comprehensive testing with nationally accredited instruments, guaranteeing performance consistency and durability.

Blait’s Two Stage Screw Refrigeration Compressor (YLG Series) is an energy-saving powerhouse designed for heavy-duty industrial cooling and freezing systems. Featuring a semi-hermetic structure, variable speed drive (VSD) technology, and dual cooling options (air-cooled/water-cooled), this screw compressor delivers exceptional efficiency, durability, and operational flexibility. With a power range of 4 kW to 355 kW and displacement of 0.8-1.2 m³/min, it caters to diverse industrial needs—from large-scale cold storage to high-demand freezing lines. The advanced YZ57 screw rotor profile minimizes energy loss, making it a cost-effective and eco-friendly choice for modern industrial facilities.

Adopting the patented YZ57 tooth profile (composed of arcs and higher-order curves), the compressor boasts a high area utilization coefficient (0.41 & 0.45) and reduced leakage triangle area, maximizing compression efficiency and minimizing energy waste.

Equipped with advanced VSD, the compressor automatically adjusts motor speed based on real-time air demand, reducing energy consumption by over 30% compared to fixed-speed models. This technology also extends the machine’s lifespan by reducing wear during startup and low-load operation.

Offering both air-cooling and water-cooling options, the compressor adapts to different industrial environments. Its mobile installation design allows flexible placement, simplifying on-site setup and maintenance.

The semi-hermetic structure enhances durability and reduces refrigerant leakage, while the oil-free design ensures clean compressed air—ideal for industries with strict hygiene requirements. The 12-liter lubricant capacity and built-in oil flow monitoring system guarantee reliable lubrication.

A user-friendly control system enables real-time monitoring of temperature, pressure, and energy consumption, allowing operators to optimize settings and prevent downtime. The built-in energy recovery system captures up to 70% of waste energy from the oil circuit and motor, reusing it for heating or other industrial processes.

Withstands pressure differences of up to 2.0 MPa, featuring a standard PTC110°C temperature sensor and INT69 FSY protection module for safe operation under extreme conditions.

Blait is a leading provider of advanced screw compressors in China, with core advantages that set us apart:

Technological leadership in screw rotor design, developed through rigorous R&D and partnerships with industry experts.

ISO9001-certified manufacturing processes, using high-quality materials and precision machining to ensure product reliability.

Versatile product range (YLG20Z-84 ~ YLG30Z-118) to match specific cooling capacity and pressure requirements.

Energy recovery technology that cuts operational costs and supports sustainability goals.

Customizable OEM solutions and responsive technical support, tailored to your industrial needs.

Comprehensive testing with nationally accredited instruments, guaranteeing performance consistency and durability.

| Parameter | Value |

|---|---|

| Product Name | Energy-Saving Screw Compressor |

| Model | Two Stage screw compressor |

| Lubrication Method | Lubricated |

| Cooling System | Air-cooled |

| Power Source | AC |

| Structure Type | Semi-hermetic |

| Installation Type | Mobile |

| Type | Single-screw compressor |

| Displacement | 0.8-1.2 m³/min |

| Power | 7.5 kW |

| Compression Stage | Single-stage |

| Lubricant Capacity | 12 liters |

| Cooling Method | Air-cooling/Water-cooling |

| Voltage | 380V/50Hz |

| Minimum Order Quantity | 1 set/unit |

| Drive Method | Direct drive |

| Oil-free Type | Yes |

| Power Range | 4 kW to 355 kW |

| Origin | China |

The Energy-Saving Variable Speed Screw Compressor by Blait is engineered for industrial use. The YLG20Z-84 model is a reliable, single-stage compressor. Its direct drive system ensures efficient and smooth operation.

This compressor operates with a displacement of 0.8-1.2 m³/min, ideal for various industrial needs. It features a semi-hermetic structure and supports both air-cooling and water-cooling.

With a power capacity of 7.5 kW and a voltage requirement of 380V/50Hz, it delivers consistent performance. The lubrication method supports smooth operation with 12 liters of lubricant.

This model offers flexibility with its mobile installation type. Its oil-free design provides clean operation, suitable for demanding applications.

The power range from 4 kW to 355 kW makes it adaptable to various industrial setups. With a minimum order quantity of 1 unit, Blait ensures accessibility for businesses of all sizes.

Blait's screw compressors are designed for durability and energy efficiency, delivering reliable results for industrial applications.

| Technical Parameter | Description |

|---|---|

| Product Model | YLG20Z-84 ~ YLG30Z-118 |

| Tooth Profile Line | YZ57, composed of arcs and higher-order curves |

| Temperature Sensor | Standard PTC110°C |

| High-Pressure Working Conditions | Pressure difference resistance of 2.0MPa |

| Protection Module | Standard INT69 FSY protection module |

| Area Utilization Coefficient | 0.41 & 0.45 |

| Oil Flow Monitoring | Equipped with oil flow switch and monitoring of oil circulation as standard |

| Leakage Triangle Area | Smaller than conventional wires, reducing leakage losses effectively |

| Engine Displacement (50Hz) | 84m³/h ~ 118m³/h |

| Engine Displacement (60Hz) | 101m³/h ~ 142m³/h |

The Variable Speed Screw Compressor by Blait is an innovative solution for diverse industrial needs. Models range from YLG20Z-84 to YLG30Z-118, featuring an advanced YZ57 tooth profile line for optimized performance. Equipped with a PTC110°C temperature sensor and INT69 FSY protection module, it ensures safety and reliability under high-pressure conditions (up to 2.0MPa). A high area utilization coefficient (0.41 & 0.45) and minimized leakage triangle area enhance energy efficiency. With engine displacement of 84m³/h to 118m³/h (50Hz) and 101m³/h to 142m³/h (60Hz), plus standard oil flow monitoring, this compressor is durable, efficient, and ideal for demanding applications.

Dimensional Drawings:

Suction, Exhaust Valve Connector

| MODEL | YLG20Z-84 | YLG25Z-100 | YLG30Z-118 |

| SL | φ54(21/8") | φ54(2 1/8") | φ54(2 1/8") |

| DL | φ42(13/8") | φ42(1 3/8") | φ42(1 3/8") |

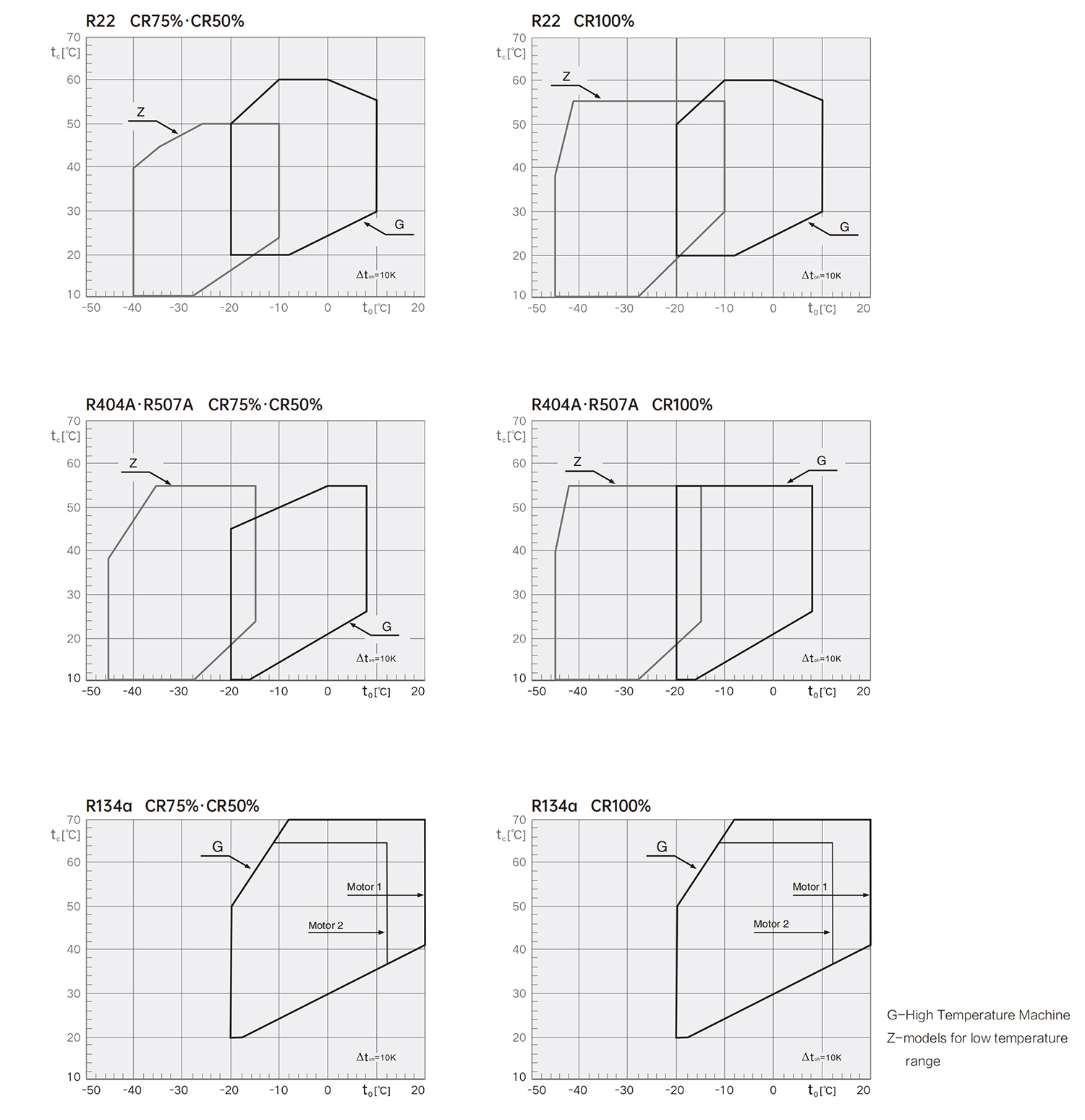

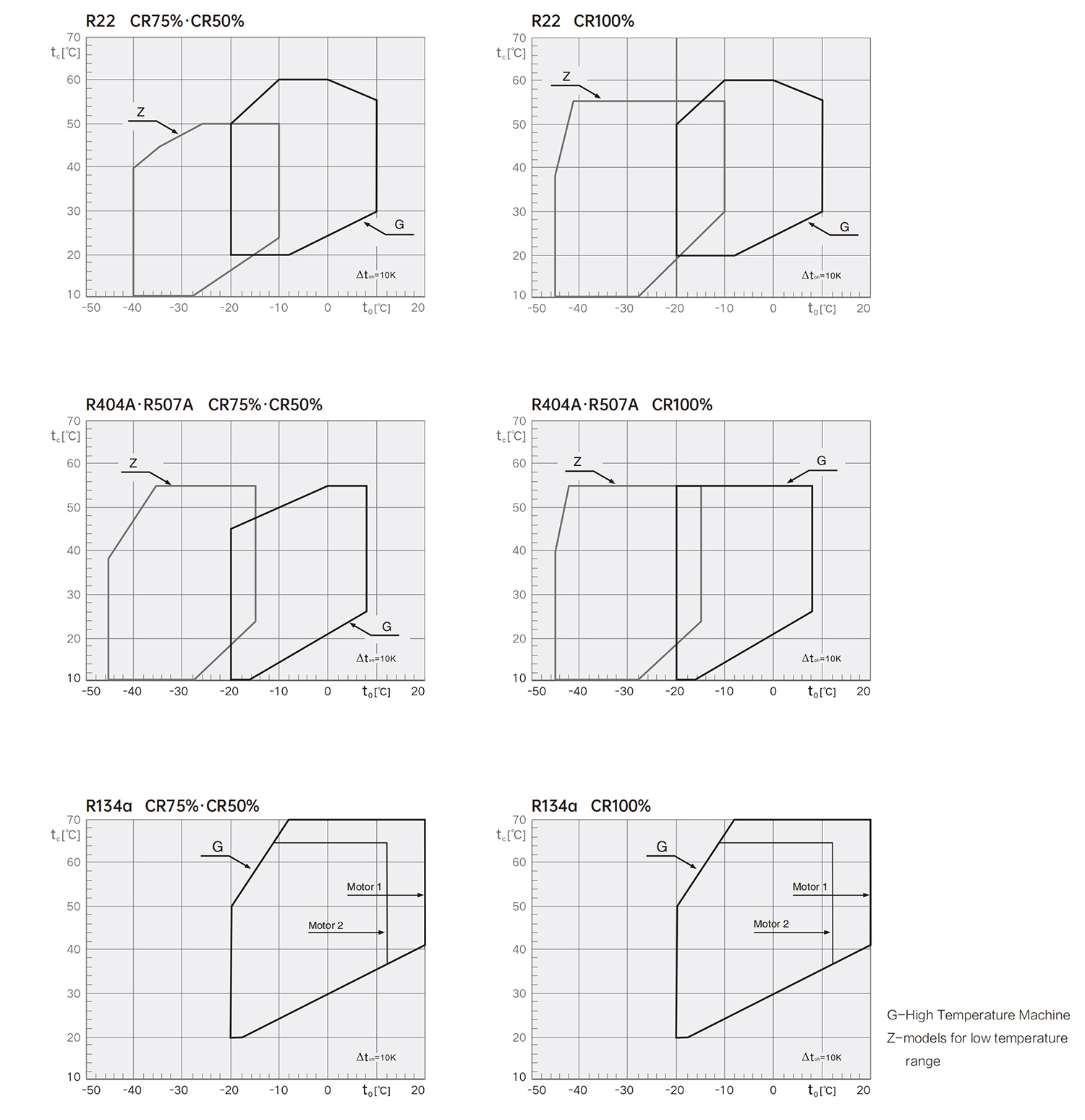

Application Scope lcon

Performance Parameter Table (R22)

Freqency 50 Hz

Based on 10 degree suction superheat;

and liquid re-cooling (Economiser operation)

| Compressor type | Cond temp(℃) | Qo(kw) Pe(kW) | Cooling capacity Qo (kw) Power consumption Pe (kW) | |||||||

| Evaporating temperatue (C ) | ||||||||||

| -10 | -15 | -20 | -25 | -30 | -35 | -40 | -45 | |||

| YLG20Z-84 | 30 | Qo | 61.9 | 51.9 | 43.4 | 35.9 | 29.3 | 23.5 | 18.4 | 14.1 |

| Pe | 19.4 | 18.5 | 16.9 | 16.6 | 15.8 | 15.2 | 14.6 | 13.9 | ||

| 40 | Qo | 59.1 | 49.5 | 41.3 | 34 | 27.6 | 21.9 | 17.1 | 12.8 | |

| Pe | 23.2 | 22.2 | 21.3 | 20.5 | 19.7 | 19.2 | 18.3 | 17.4 | ||

| 50 | Qo | 55.1 | 46.3 | 38.4 | 31.4 | 25.2 | 19.8 | 15 | ||

| Pe | 27.8 | 26.8 | 26.2 | 25.3 | 24.5 | 23.2 | 21.8 | |||

| YLG25Z-100 | 30 | Qo | 71.4 | 60.6 | 50.9 | 42.3 | 34.7 | 28 | 22.2 | 17.2 |

| Pe | 22.2 | 21.3 | 20.5 | 19.8 | 18.6 | 17.9 | 17.2 | 16.6 | ||

| 40 | Qo | 68.7 | 58.1 | 48.6 | 40.3 | 32.8 | 26.4 | 20.7 | 15.8 | |

| Pe | 26.5 | 25.4 | 24.5 | 23.6 | 22.7 | 21.8 | 20.9 | 20.1 | ||

| 50 | Qo | 65.1 | 54.9 | 45.7 | 37.5 | 30.3 | 23.9 | 18.4 | ||

| Pe | 31.8 | 30.7 | 29.5 | 28.6 | 27.7 | 26.1 | 25 | |||

| YLG30Z-118 | 30 | Qo | 83.1 | 70.5 | 59.3 | 49.4 | 40.6 | 32.8 | 26.1 | 20.2 |

| Pe | 25.9 | 24.7 | 23.5 | 22.4 | 21.4 | 20.5 | 19.6 | 18.8 | ||

| 40 | Qo | 79.9 | 67.6 | 56.7 | 47 | 38.5 | 30.9 | 24.4 | 18.7 | |

| Pe | 30.5 | 29.3 | 28.2 | 27.1 | 26 | 25.1 | 23.9 | 22.8 | ||

| 50 | Qo | 75.2 | 63.6 | 53.1 | 43.8 | 35.5 | 28.2 | 21.8 | ||

| Pe | 36.5 | 35.6 | 33.9 | 32.6 | 31.5 | 30.3 | 28.7 | |||

Performance Parameter Table (R404A/R507A)

Freqency 50 Hz

Based on 10 degree suction superheat;

and liquid re-cooling (Economiser operation)

| Compressor type | Cond temp(℃) | Qo(kw) Pe(kW) | Cooling capacity Qo (kw) Power consumption Pe (kW) | ||||||

| Evaporating temperatue (C ) | |||||||||

| -15 | -20 | -25 | -30 | -35 | -40 | -45 | |||

| YLG20Z-84 | 30 | Qo | 56.8 | 47.9 | 40 | 33 | 26.8 | 21.4 | 16.7 |

| Pe | 22.6 | 22.1 | 21.4 | 20.7 | 19.7 | 18.6 | 18 | ||

| 40 | Qo | 53.7 | 53.7 | 37.5 | 30.7 | 24.7 | 19.5 | 14.9 | |

| Pe | 28.3 | 28.3 | 26.8 | 25.8 | 24.7 | 23.5 | 21.9 | ||

| 50 | Qo | 34.2 | 27.1 | 21.6 | 16.5 | 11.9 | |||

| Pe | 32.1 | 30.9 | 29.5 | 28.5 | 26.3 | ||||

| YLG25Z-100 | 30 | Qo | 66.3 | 55.9 | 46.7 | 38.5 | 31.3 | 25.1 | 19.6 |

| Pe | 25.3 | 24.5 | 23.8 | 22.9 | 22.5 | 21.2 | 20.3 | ||

| 40 | Qo | 62.6 | 52.7 | 43.9 | 36 | 29.1 | 23 | 17.7 | |

| Pe | 31.8 | 31.2 | 28.8 | 29.2 | 28.2 | 26.5 | 24.8 | ||

| 50 | Qo | 42.6 | 33.7 | 25.7 | 19.8 | 14.6 | |||

| Pe | 40.2 | 37.7 | 34.8 | 32.6 | 30.2 | ||||

| YLG30Z-118 | 30 | Qo | 75.6 | 63.9 | 53.4 | 44.1 | 36 | 28.9 | 22.7 |

| Pe | 29.1 | 28.1 | 27.2 | 26.3 | 24.9 | 24.1 | 22.8 | ||

| 40 | Qo | 71.4 | 60.3 | 50.3 | 41.5 | 33.8 | 26.9 | 21 | |

| Pe | 36.2 | 35.2 | 33.8 | 32.8 | 31.2 | 30 | 28.5 | ||

| 50 | Qo | 46.2 | 38 | 30.8 | 24 | 18.3 | |||

| Pe | 41.5 | 40.1 | 38.4 | 37.7 | 35.2 | ||||

Technical Data Sheet

| Compressor type | Displacement (50Hz) | Displacement (60Hz) | Discharge pipe | Suction pipe | Energy regulation | Power supply | Maximumoperating current | Maximumpower | Start/locked rotor current | Weight |

| m³/h | mm (inch) | % | V/φ/Hz | A | kW | A | kg | |||

| YLG20Z-84 | 84 | 101 | φ42(15/8") | φ54(21/8") | 100/90/55 | 400±10% △/△△3~/50HZ 460±10% △/△△3~/60HZ Part Winding | 48 | 29 | 129/210 | 166 |

| YLG30G-84 | 84 | 101 | 100/90/70 | 52 | 33 | 126/218 | 170 | |||

| YLG25Z-100 | 100 | 121 | 100/80/45 | 52 | 33 | 126/218 | 169 | |||

| YLG35G-100 | 100 | 121 | 100/85/60 | 58 | 37.3 | 153/266 | 178 | |||

| YLG30Z-118 | 118 | 142 | 100/75/45 | 58 | 37 | 153/266 | 174 | |||

| YLG40G-118 | 118 | 142 | 100/80/55 | 66 | 42 | 182/311 | 183 | |||

| Parameter | Value |

|---|---|

| Product Name | Energy-Saving Screw Compressor |

| Model | Two Stage screw compressor |

| Lubrication Method | Lubricated |

| Cooling System | Air-cooled |

| Power Source | AC |

| Structure Type | Semi-hermetic |

| Installation Type | Mobile |

| Type | Single-screw compressor |

| Displacement | 0.8-1.2 m³/min |

| Power | 7.5 kW |

| Compression Stage | Single-stage |

| Lubricant Capacity | 12 liters |

| Cooling Method | Air-cooling/Water-cooling |

| Voltage | 380V/50Hz |

| Minimum Order Quantity | 1 set/unit |

| Drive Method | Direct drive |

| Oil-free Type | Yes |

| Power Range | 4 kW to 355 kW |

| Origin | China |

The Energy-Saving Variable Speed Screw Compressor by Blait is engineered for industrial use. The YLG20Z-84 model is a reliable, single-stage compressor. Its direct drive system ensures efficient and smooth operation.

This compressor operates with a displacement of 0.8-1.2 m³/min, ideal for various industrial needs. It features a semi-hermetic structure and supports both air-cooling and water-cooling.

With a power capacity of 7.5 kW and a voltage requirement of 380V/50Hz, it delivers consistent performance. The lubrication method supports smooth operation with 12 liters of lubricant.

This model offers flexibility with its mobile installation type. Its oil-free design provides clean operation, suitable for demanding applications.

The power range from 4 kW to 355 kW makes it adaptable to various industrial setups. With a minimum order quantity of 1 unit, Blait ensures accessibility for businesses of all sizes.

Blait's screw compressors are designed for durability and energy efficiency, delivering reliable results for industrial applications.

| Technical Parameter | Description |

|---|---|

| Product Model | YLG20Z-84 ~ YLG30Z-118 |

| Tooth Profile Line | YZ57, composed of arcs and higher-order curves |

| Temperature Sensor | Standard PTC110°C |

| High-Pressure Working Conditions | Pressure difference resistance of 2.0MPa |

| Protection Module | Standard INT69 FSY protection module |

| Area Utilization Coefficient | 0.41 & 0.45 |

| Oil Flow Monitoring | Equipped with oil flow switch and monitoring of oil circulation as standard |

| Leakage Triangle Area | Smaller than conventional wires, reducing leakage losses effectively |

| Engine Displacement (50Hz) | 84m³/h ~ 118m³/h |

| Engine Displacement (60Hz) | 101m³/h ~ 142m³/h |

The Variable Speed Screw Compressor by Blait is an innovative solution for diverse industrial needs. Models range from YLG20Z-84 to YLG30Z-118, featuring an advanced YZ57 tooth profile line for optimized performance. Equipped with a PTC110°C temperature sensor and INT69 FSY protection module, it ensures safety and reliability under high-pressure conditions (up to 2.0MPa). A high area utilization coefficient (0.41 & 0.45) and minimized leakage triangle area enhance energy efficiency. With engine displacement of 84m³/h to 118m³/h (50Hz) and 101m³/h to 142m³/h (60Hz), plus standard oil flow monitoring, this compressor is durable, efficient, and ideal for demanding applications.

Dimensional Drawings:

Suction, Exhaust Valve Connector

| MODEL | YLG20Z-84 | YLG25Z-100 | YLG30Z-118 |

| SL | φ54(21/8") | φ54(2 1/8") | φ54(2 1/8") |

| DL | φ42(13/8") | φ42(1 3/8") | φ42(1 3/8") |

Application Scope lcon

Performance Parameter Table (R22)

Freqency 50 Hz

Based on 10 degree suction superheat;

and liquid re-cooling (Economiser operation)

| Compressor type | Cond temp(℃) | Qo(kw) Pe(kW) | Cooling capacity Qo (kw) Power consumption Pe (kW) | |||||||

| Evaporating temperatue (C ) | ||||||||||

| -10 | -15 | -20 | -25 | -30 | -35 | -40 | -45 | |||

| YLG20Z-84 | 30 | Qo | 61.9 | 51.9 | 43.4 | 35.9 | 29.3 | 23.5 | 18.4 | 14.1 |

| Pe | 19.4 | 18.5 | 16.9 | 16.6 | 15.8 | 15.2 | 14.6 | 13.9 | ||

| 40 | Qo | 59.1 | 49.5 | 41.3 | 34 | 27.6 | 21.9 | 17.1 | 12.8 | |

| Pe | 23.2 | 22.2 | 21.3 | 20.5 | 19.7 | 19.2 | 18.3 | 17.4 | ||

| 50 | Qo | 55.1 | 46.3 | 38.4 | 31.4 | 25.2 | 19.8 | 15 | ||

| Pe | 27.8 | 26.8 | 26.2 | 25.3 | 24.5 | 23.2 | 21.8 | |||

| YLG25Z-100 | 30 | Qo | 71.4 | 60.6 | 50.9 | 42.3 | 34.7 | 28 | 22.2 | 17.2 |

| Pe | 22.2 | 21.3 | 20.5 | 19.8 | 18.6 | 17.9 | 17.2 | 16.6 | ||

| 40 | Qo | 68.7 | 58.1 | 48.6 | 40.3 | 32.8 | 26.4 | 20.7 | 15.8 | |

| Pe | 26.5 | 25.4 | 24.5 | 23.6 | 22.7 | 21.8 | 20.9 | 20.1 | ||

| 50 | Qo | 65.1 | 54.9 | 45.7 | 37.5 | 30.3 | 23.9 | 18.4 | ||

| Pe | 31.8 | 30.7 | 29.5 | 28.6 | 27.7 | 26.1 | 25 | |||

| YLG30Z-118 | 30 | Qo | 83.1 | 70.5 | 59.3 | 49.4 | 40.6 | 32.8 | 26.1 | 20.2 |

| Pe | 25.9 | 24.7 | 23.5 | 22.4 | 21.4 | 20.5 | 19.6 | 18.8 | ||

| 40 | Qo | 79.9 | 67.6 | 56.7 | 47 | 38.5 | 30.9 | 24.4 | 18.7 | |

| Pe | 30.5 | 29.3 | 28.2 | 27.1 | 26 | 25.1 | 23.9 | 22.8 | ||

| 50 | Qo | 75.2 | 63.6 | 53.1 | 43.8 | 35.5 | 28.2 | 21.8 | ||

| Pe | 36.5 | 35.6 | 33.9 | 32.6 | 31.5 | 30.3 | 28.7 | |||

Performance Parameter Table (R404A/R507A)

Freqency 50 Hz

Based on 10 degree suction superheat;

and liquid re-cooling (Economiser operation)

| Compressor type | Cond temp(℃) | Qo(kw) Pe(kW) | Cooling capacity Qo (kw) Power consumption Pe (kW) | ||||||

| Evaporating temperatue (C ) | |||||||||

| -15 | -20 | -25 | -30 | -35 | -40 | -45 | |||

| YLG20Z-84 | 30 | Qo | 56.8 | 47.9 | 40 | 33 | 26.8 | 21.4 | 16.7 |

| Pe | 22.6 | 22.1 | 21.4 | 20.7 | 19.7 | 18.6 | 18 | ||

| 40 | Qo | 53.7 | 53.7 | 37.5 | 30.7 | 24.7 | 19.5 | 14.9 | |

| Pe | 28.3 | 28.3 | 26.8 | 25.8 | 24.7 | 23.5 | 21.9 | ||

| 50 | Qo | 34.2 | 27.1 | 21.6 | 16.5 | 11.9 | |||

| Pe | 32.1 | 30.9 | 29.5 | 28.5 | 26.3 | ||||

| YLG25Z-100 | 30 | Qo | 66.3 | 55.9 | 46.7 | 38.5 | 31.3 | 25.1 | 19.6 |

| Pe | 25.3 | 24.5 | 23.8 | 22.9 | 22.5 | 21.2 | 20.3 | ||

| 40 | Qo | 62.6 | 52.7 | 43.9 | 36 | 29.1 | 23 | 17.7 | |

| Pe | 31.8 | 31.2 | 28.8 | 29.2 | 28.2 | 26.5 | 24.8 | ||

| 50 | Qo | 42.6 | 33.7 | 25.7 | 19.8 | 14.6 | |||

| Pe | 40.2 | 37.7 | 34.8 | 32.6 | 30.2 | ||||

| YLG30Z-118 | 30 | Qo | 75.6 | 63.9 | 53.4 | 44.1 | 36 | 28.9 | 22.7 |

| Pe | 29.1 | 28.1 | 27.2 | 26.3 | 24.9 | 24.1 | 22.8 | ||

| 40 | Qo | 71.4 | 60.3 | 50.3 | 41.5 | 33.8 | 26.9 | 21 | |

| Pe | 36.2 | 35.2 | 33.8 | 32.8 | 31.2 | 30 | 28.5 | ||

| 50 | Qo | 46.2 | 38 | 30.8 | 24 | 18.3 | |||

| Pe | 41.5 | 40.1 | 38.4 | 37.7 | 35.2 | ||||

Technical Data Sheet

| Compressor type | Displacement (50Hz) | Displacement (60Hz) | Discharge pipe | Suction pipe | Energy regulation | Power supply | Maximumoperating current | Maximumpower | Start/locked rotor current | Weight |

| m³/h | mm (inch) | % | V/φ/Hz | A | kW | A | kg | |||

| YLG20Z-84 | 84 | 101 | φ42(15/8") | φ54(21/8") | 100/90/55 | 400±10% △/△△3~/50HZ 460±10% △/△△3~/60HZ Part Winding | 48 | 29 | 129/210 | 166 |

| YLG30G-84 | 84 | 101 | 100/90/70 | 52 | 33 | 126/218 | 170 | |||

| YLG25Z-100 | 100 | 121 | 100/80/45 | 52 | 33 | 126/218 | 169 | |||

| YLG35G-100 | 100 | 121 | 100/85/60 | 58 | 37.3 | 153/266 | 178 | |||

| YLG30Z-118 | 118 | 142 | 100/75/45 | 58 | 37 | 153/266 | 174 | |||

| YLG40G-118 | 118 | 142 | 100/80/55 | 66 | 42 | 182/311 | 183 | |||

Delivers consistent cooling for massive cold storage facilities, maintaining ultra-low temperatures for long-term preservation of goods.

Supports manufacturing processes that require high-capacity cooling, such as chemical production, plastic molding, and metal processing.

Provides rapid and stable freezing for food processing plants, ensuring product quality and extending shelf life.

Integrates with industrial HVAC systems to regulate temperature in large factories, warehouses, and commercial buildings.

Delivers consistent cooling for massive cold storage facilities, maintaining ultra-low temperatures for long-term preservation of goods.

Supports manufacturing processes that require high-capacity cooling, such as chemical production, plastic molding, and metal processing.

Provides rapid and stable freezing for food processing plants, ensuring product quality and extending shelf life.

Integrates with industrial HVAC systems to regulate temperature in large factories, warehouses, and commercial buildings.

Monitor lubricant levels regularly and replace every 1,000 hours of operation.

Inspect the oil flow switch and cooling system monthly to ensure proper function.

Clean air/water cooling filters quarterly to prevent clogging and efficiency loss.

Check screw rotor alignment and seals annually for leakage or wear.

Blait offers a 1-year warranty on the Two Stage Screw Refrigeration Compressor, covering defects in materials and workmanship. Our global service network provides on-site maintenance, spare parts supply, and technical consultation, ensuring your compressor operates at peak performance for years to come.

Monitor lubricant levels regularly and replace every 1,000 hours of operation.

Inspect the oil flow switch and cooling system monthly to ensure proper function.

Clean air/water cooling filters quarterly to prevent clogging and efficiency loss.

Check screw rotor alignment and seals annually for leakage or wear.

Blait offers a 1-year warranty on the Two Stage Screw Refrigeration Compressor, covering defects in materials and workmanship. Our global service network provides on-site maintenance, spare parts supply, and technical consultation, ensuring your compressor operates at peak performance for years to come.

No products found