Call Us

+86-18072289720

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-15 Origin: Site

Ever wondered how your fridge keeps your food fresh or your air conditioner cools your home? It's all thanks to the refrigeration cycle. This cycle is crucial in our daily lives, moving heat to create a cooler environment. In this post, you'll learn about the refrigeration cycle's components, including the vital refrigeration compressor, and its importance in everyday life.

The refrigeration cycle operates on a simple but powerful idea: it moves heat from one place to another. It doesn’t create cold; it removes heat. Think of it like a heat shuttle, pulling warmth out of a space and dumping it somewhere else. This process relies on a special fluid called refrigerant, which absorbs heat when it evaporates and releases heat when it condenses.

Heat absorption happens in the evaporator, where the refrigerant evaporates at low pressure, pulling heat from the surrounding air or space. This cools the area. The absorbed heat turns the refrigerant from liquid to vapor. Then, the refrigerant carries this heat to the condenser, where it releases heat to the outside air as it condenses back into liquid. This cycle repeats continuously to maintain a cool environment.

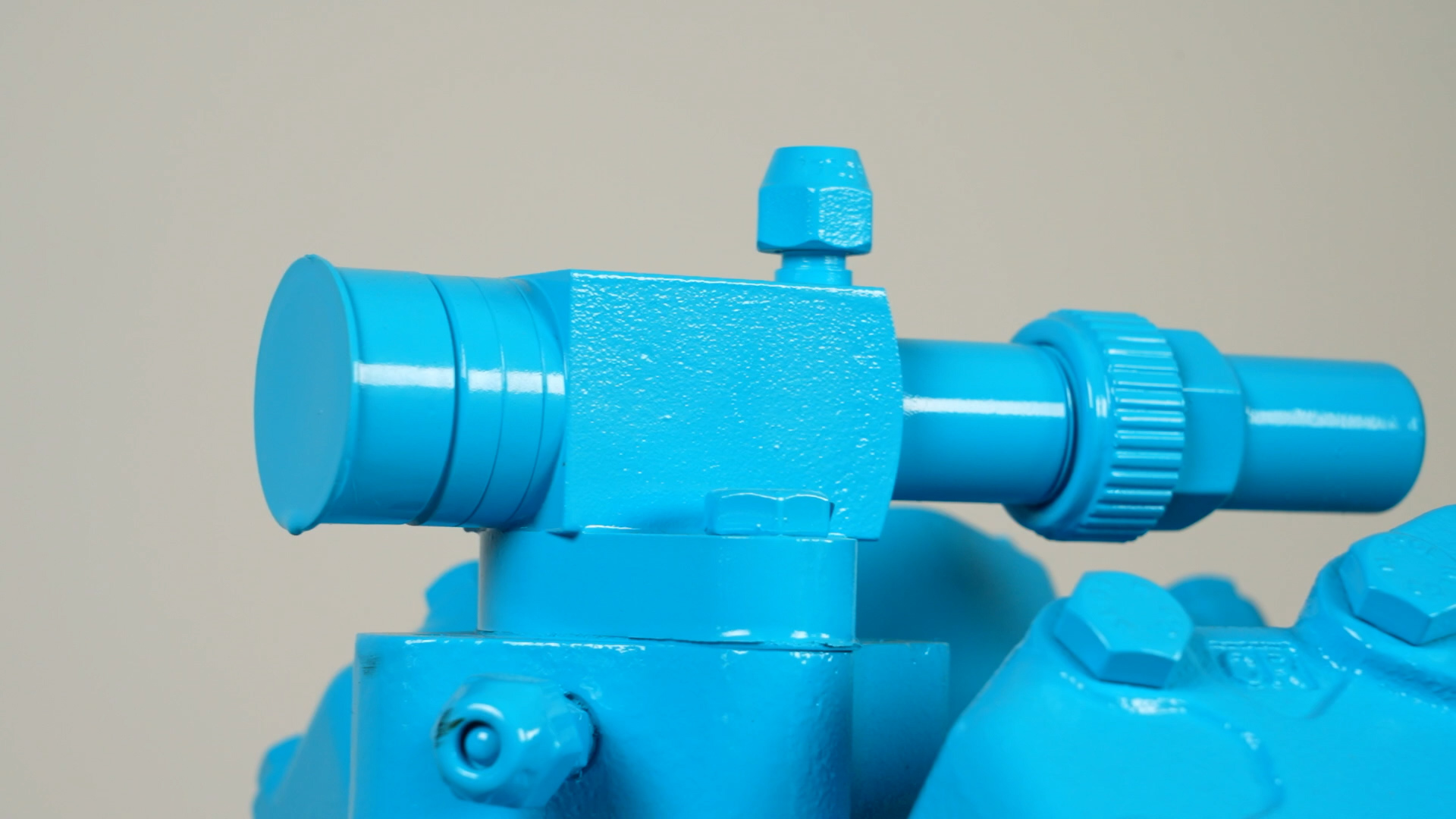

The compressor is the heart of the refrigeration cycle. It pumps the refrigerant through the system and controls the pressure. Starting with low-pressure, cool vapor from the evaporator, the compressor squeezes it into a high-pressure, hot vapor. This increase in pressure raises the refrigerant’s temperature, preparing it to release heat in the condenser.

Without the compressor, the refrigerant wouldn’t flow, and the cycle would stop. It ensures the refrigerant moves from the cold side (evaporator) to the hot side (condenser) efficiently. Compressors come in various types, but their main job remains the same: compress vapor to high pressure and temperature.

Note: Proper compressor function is essential for efficient heat transfer and overall refrigeration system performance.

The compressor is the system’s powerhouse. It takes in low-pressure, cool refrigerant vapor from the evaporator and squeezes it into high-pressure, hot vapor. This step raises the refrigerant’s temperature and pressure, preparing it for heat release in the condenser. Without the compressor, refrigerant wouldn’t flow, and the cycle would stop. It’s typically located in the outdoor unit of air conditioning systems.

Next, the hot, high-pressure vapor enters the condenser. This component acts like a heat exchanger. It cools the refrigerant by releasing heat into the outside air. As the refrigerant cools, it changes from vapor to liquid—a process called condensation. The condenser ensures the refrigerant is a high-pressure, low-temperature liquid before it moves on. Air-cooled condensers use fans to blow air across coils, while water-cooled ones circulate water to remove heat.

After the condenser, the liquid refrigerant passes through the expansion device. This part reduces the refrigerant’s pressure suddenly. The drop in pressure causes some of the liquid to “flash” into vapor, creating a cold, two-phase mixture. This flashing prepares the refrigerant to absorb heat in the evaporator. Expansion devices come in several types, including thermostatic expansion valves (TXV), fixed orifices, and electronic expansion valves (EEV).

Finally, the cold, low-pressure refrigerant enters the evaporator. This is the part inside your home or the cooled space. The evaporator absorbs heat from the air, causing the refrigerant to boil and turn back into vapor. A fan blows air across the evaporator coil, cooling the air and removing moisture. The refrigerant, now a low-pressure vapor, returns to the compressor to start the cycle again.

Note: Each component in the refrigeration cycle plays a vital role in moving heat and maintaining efficiency; proper function ensures consistent cooling performance.

Refrigeration compressors come in several types, each designed to move refrigerant vapor efficiently through the system. Their main job remains the same: compress low-pressure vapor into high-pressure, high-temperature vapor. However, the way they achieve this varies, affecting efficiency, noise, size, and cost.

These are among the oldest and most common types. They work like a car engine’s piston, moving back and forth inside cylinders. As the piston moves down, it draws in low-pressure refrigerant vapor. When it moves up, it compresses the vapor and pushes it out at high pressure.

Advantages:

Durable and reliable

Good for a wide range of capacities

Relatively simple design

Disadvantages:

Can be noisy and produce vibrations

More moving parts mean more wear and tear

Scroll compressors use two spiral-shaped scrolls. One scroll remains fixed, while the other orbits around it. This motion traps and compresses refrigerant vapor in pockets between the scrolls.

Advantages:

Smooth and quiet operation

Fewer moving parts, so less maintenance

High efficiency, especially at partial loads

Disadvantages:

Usually more expensive upfront

Limited capacity range compared to reciprocating compressors

Rotary compressors have a roller or blade that rotates inside a cylinder. As it spins, it traps refrigerant vapor and compresses it by reducing the space inside the cylinder.

Advantages:

Compact and lightweight

Quiet operation

Good for small to medium cooling capacities

Disadvantages:

Less efficient than scroll compressors at larger sizes

Can wear faster if not properly maintained

| Feature | Reciprocating | Scroll | Rotary |

|---|---|---|---|

| Noise Level | Moderate to High | Low | Low |

| Efficiency | Moderate | High | Moderate |

| Maintenance | Higher | Lower | Moderate |

| Size & Weight | Larger and heavier | Moderate | Small and lightweight |

| Cost | Generally lower | Higher | Moderate |

| Best Use | Wide range, industrial | Residential, commercial | Small to medium systems |

Choosing the right compressor depends on your system’s size, application, and budget. Scroll compressors are popular for residential AC due to quiet operation and efficiency. Reciprocating compressors suit larger industrial systems where durability matters. Rotary compressors fit well in compact systems like mini-splits.

Tip: Selecting a compressor type that matches your system’s size and use case improves efficiency and reduces maintenance costs over time.

The refrigeration cycle is a continuous loop made up of four key processes: compression, condensation, expansion, and evaporation. Each step changes the refrigerant’s pressure and temperature, allowing it to absorb heat from one area and release it elsewhere.

The cycle begins at the compressor. It takes in low-pressure, cool refrigerant vapor from the evaporator. The compressor squeezes this vapor, raising its pressure and temperature sharply. This high-pressure, hot vapor is then pushed into the condenser. Imagine the compressor as a pump that moves refrigerant through the system, creating the pressure difference needed for heat transfer.

Next, the hot, high-pressure vapor enters the condenser coil. Here, the refrigerant releases heat to the outside air or water, cooling down as it moves through the coil. As it cools, the vapor condenses into a high-pressure liquid. This phase change from vapor to liquid releases a lot of heat, which is why the condenser feels warm during operation.

The high-pressure liquid refrigerant then flows to the expansion device, such as a thermostatic expansion valve or fixed orifice. This device suddenly reduces the pressure of the refrigerant. The rapid pressure drop causes part of the liquid to flash into vapor, creating a cold, low-pressure liquid-vapor mixture. This mixture is ready to absorb heat in the next stage.

Finally, the cold, low-pressure refrigerant enters the evaporator coil inside the cooled space. As warm air blows over the coil, the refrigerant absorbs heat and evaporates, turning back into vapor. This heat absorption cools the surrounding air. The refrigerant, now a low-pressure vapor, returns to the compressor to start the cycle again.

Tip: Regularly check superheat and subcooling values during maintenance to ensure each stage of the refrigeration cycle operates efficiently and prevents compressor damage.

The refrigeration cycle is a finely tuned process, but several common problems can disrupt its efficiency and performance. Understanding these issues helps in early detection and timely repair, saving energy and preventing costly breakdowns.

Low refrigerant levels often result from leaks in the system. When refrigerant escapes, the cycle cannot absorb and transfer heat effectively. This causes the evaporator coil to become too cold, potentially freezing up, and the compressor to work harder, risking damage. Signs of leaks include reduced cooling, hissing sounds near pipes, or oily residue around fittings.

Leaks not only reduce efficiency but harm the environment, especially if the refrigerant is a greenhouse gas. Regular leak detection and prompt repairs are essential. Technicians use electronic leak detectors or ultraviolet dye to locate leaks during maintenance.

Both condenser and evaporator coils need to be clean to function properly. Dirty coils act as insulation, blocking heat transfer. A dirty condenser coil can’t release heat efficiently, causing refrigerant to remain too hot and pressure to rise. This makes the compressor work harder and consume more energy.

Similarly, dirty evaporator coils reduce heat absorption from the indoor air, leading to poor cooling and potential coil freezing. Dust, dirt, and debris buildup from poor filtration or lack of cleaning are common causes. Regular coil cleaning keeps the system running smoothly and lowers energy costs.

Frozen evaporator coils happen when the refrigerant flow is insufficient or airflow is restricted. Causes include low refrigerant, dirty coils, or blocked air filters. Ice buildup prevents heat absorption, reducing cooling power and causing the system to shut off prematurely, a phenomenon called short cycling.

Short cycling not only wastes energy but also strains the compressor, shortening its lifespan. To prevent this, maintain proper refrigerant charge, ensure clean coils and filters, and verify that fans work correctly.

Several factors cause refrigeration systems to consume more energy than necessary:

Low refrigerant or leaks forcing the compressor to run longer.

Dirty coils reducing heat exchange efficiency.

Malfunctioning fans or controls.

Short cycling increasing start-stop cycles.

Aging equipment with worn parts.

High energy use raises operating costs and may indicate system issues needing attention. Regular maintenance, including refrigerant checks, coil cleaning, and component inspections, helps optimize energy efficiency.

Tip: Schedule routine inspections focusing on refrigerant levels, coil cleanliness, and airflow to prevent common refrigeration cycle problems and maintain system efficiency.

Proper maintenance keeps refrigeration systems running smoothly and efficiently. Neglecting upkeep can cause performance drops, higher energy bills, and costly repairs. Here’s what you need to know to maintain and optimize your refrigeration cycle.

Routine checks help catch problems early. Regular maintenance includes inspecting all components, cleaning coils, and verifying refrigerant levels. This prevents unexpected breakdowns and extends equipment life. Scheduling professional service at least once a year ensures the system gets a thorough checkup.

Refrigerant leaks reduce cooling capacity and increase energy use. They also harm the environment. During maintenance, technicians use leak detectors or UV dyes to find leaks. Fixing leaks promptly restores proper refrigerant charge and system balance. Keeping refrigerant levels correct protects the compressor and improves efficiency.

Superheat and subcooling are key indicators of system health. Superheat shows if the refrigerant vapor entering the compressor is dry enough to prevent damage. Subcooling confirms the liquid refrigerant entering the expansion device is fully cooled for efficient operation.

Technicians measure these values during maintenance to verify the system operates within recommended ranges. Incorrect superheat or subcooling signals issues like improper refrigerant charge, faulty expansion valves, or airflow problems.

Clean coils regularly: Dirty coils block heat transfer, causing the compressor to work harder.

Maintain airflow: Ensure filters and fans are clean and unobstructed.

Use variable speed drives: These adjust compressor and fan speeds to match cooling demand, saving energy.

Monitor system controls: Proper thermostat and sensor operation optimize cycling and reduce wear.

Upgrade components: Modern compressors and expansion devices improve efficiency and reliability.

Implementing these tips boosts system performance, lowers energy costs, and extends equipment life.

Tip: Schedule seasonal professional maintenance focusing on refrigerant levels, coil cleanliness, and superheat/subcooling checks to keep refrigeration systems operating at peak efficiency.

The refrigeration cycle efficiently moves heat using components like compressors, condensers, and evaporators. Refrigeration compressors are crucial for maintaining efficient cooling by compressing refrigerant vapor. Zhejiang Briliant Refrigeration Equipment Co., Ltd. offers advanced refrigeration solutions, ensuring optimal performance and energy efficiency. Their products provide reliable cooling and superior value.

A: The refrigeration compressor is crucial as it pumps refrigerant through the system, increasing its pressure and temperature to facilitate heat release in the condenser.

A: The refrigeration cycle involves compression, condensation, expansion, and evaporation, allowing refrigerant to absorb heat from one area and release it elsewhere.

A: Regular maintenance ensures efficient operation, prevents breakdowns, and extends the system’s lifespan by checking refrigerant levels, cleaning coils, and verifying airflow.

No products found