Call Us

+86-18072289720

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

YLG90Z-315

Blait

Blait’s High-Efficiency Industrial Screw Refrigeration Compressor is a professional-grade solution engineered for demanding commercial and industrial cooling and freezing applications. Designed with a robust semi-hermetic structure and advanced screw rotor technology, this compressor delivers stable performance, energy savings, and long service life—making it ideal for cold storage, food processing facilities, industrial refrigeration plants, and heavy-duty freezing systems. Whether operating under high-pressure or low-temperature conditions, it maintains superior cooling capacity while minimizing energy consumption, addressing the core needs of businesses seeking reliable and cost-effective refrigeration solutions.

Optimized screw rotor profiles (YZ57 tooth profile line, composed of arcs and higher-order curves) and advanced motor technology work in tandem to reduce power consumption without compromising cooling output. The compressor’s minimized leakage triangle area and high area utilization coefficient (0.41 & 0.45) further enhance energy efficiency, cutting operational costs significantly.

The semi-hermetic design allows internal inspection and component access without full system shutdown, reducing downtime and maintenance complexity. Built with industrial-grade materials resistant to wear, corrosion, and high pressure, it ensures durability even in harsh industrial environments.

Engineered for smooth performance, this industrial screw compressor features low vibration and noise levels, making it suitable for sensitive settings such as food processing facilities and pharmaceutical cold storage where quiet operation is critical.

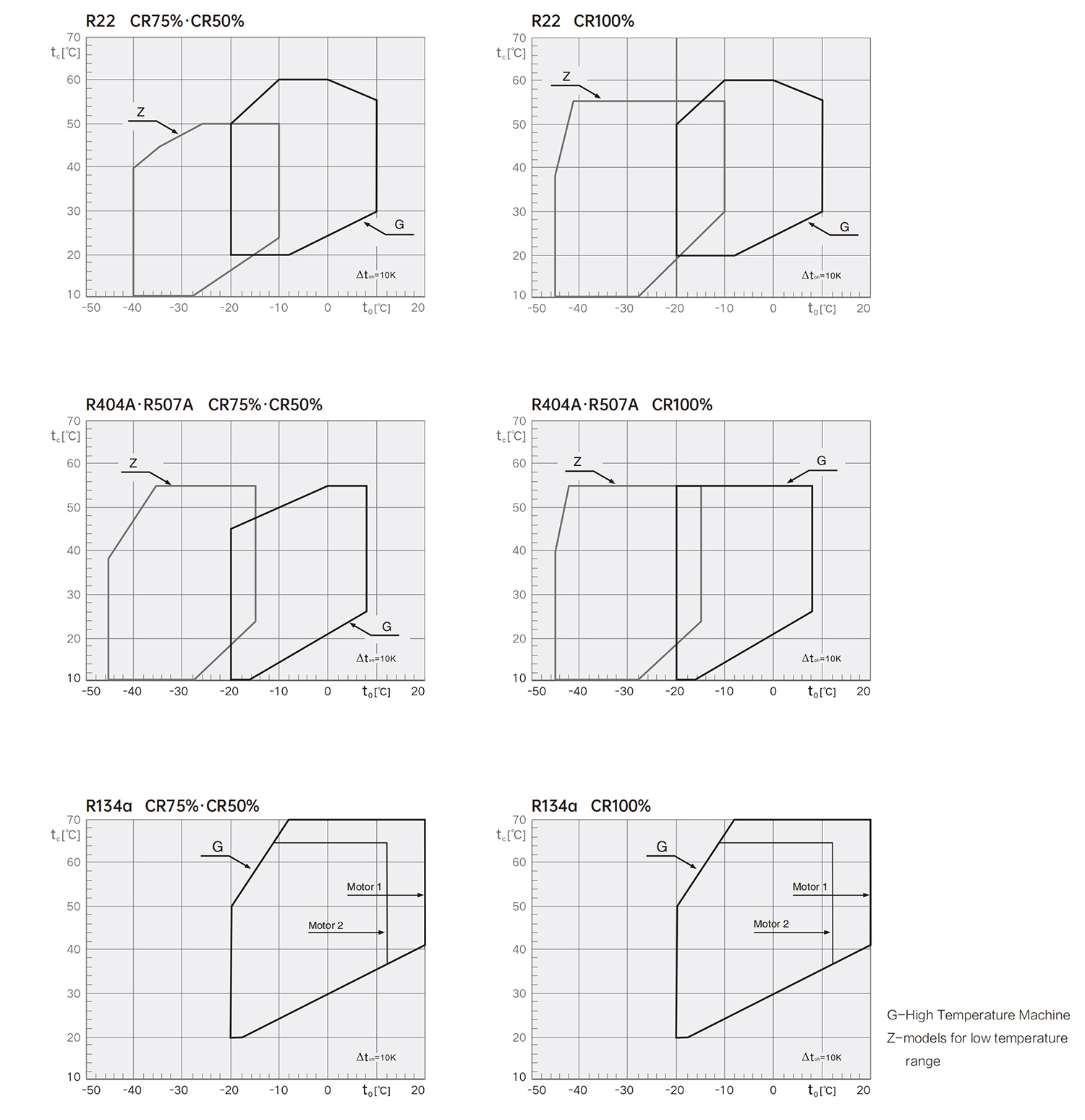

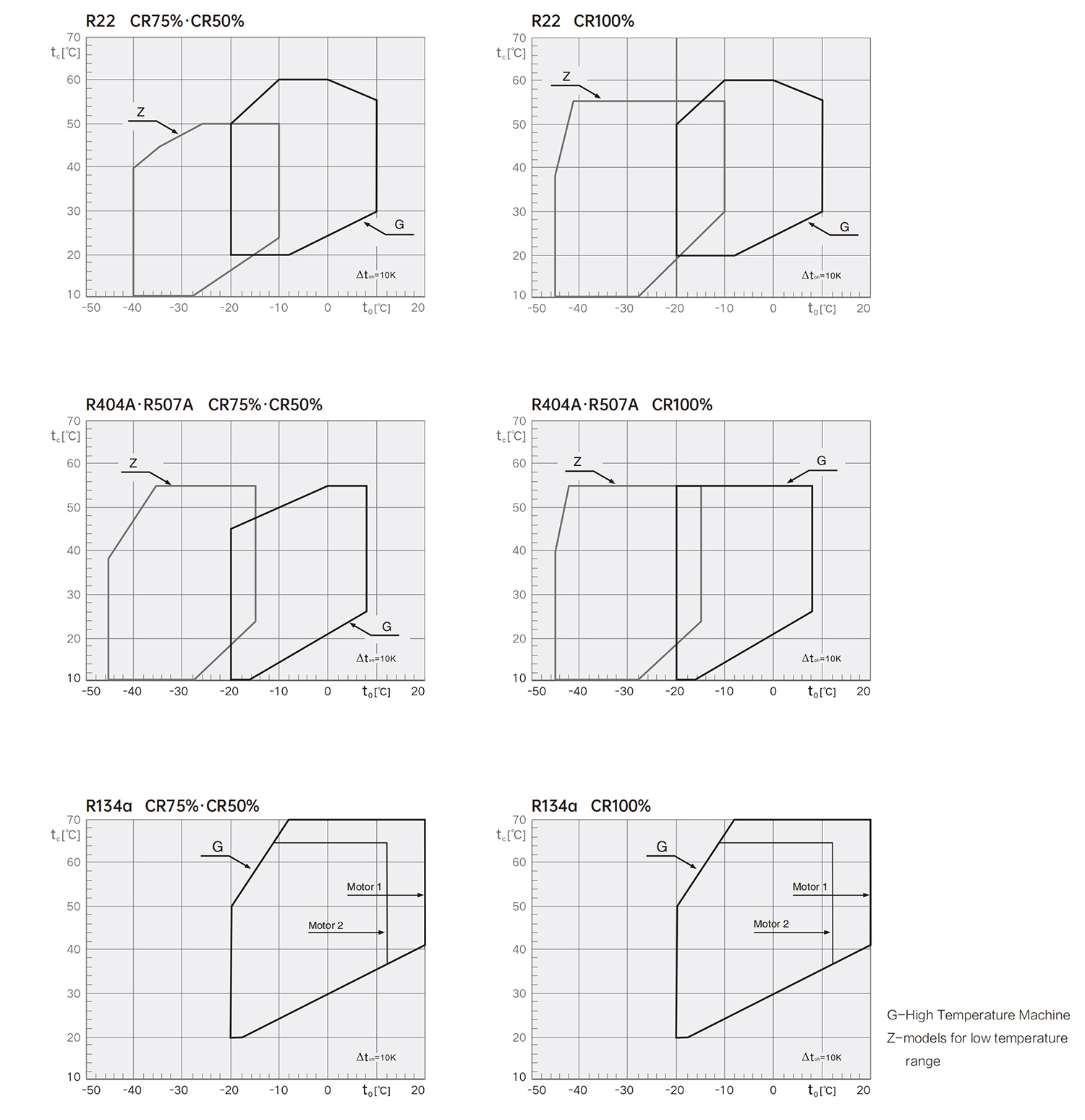

Supports both high and low-temperature applications (-50℃ to 20℃) for flexible system integration. The adjustable capacity function enables precise control over refrigeration output, improving part-load efficiency and adapting to variable load conditions seamlessly.

Tailored Industrial Solutions: Blait offers OEM and customized compressor specifications, including voltage, power, and installation accessories, to match unique project requirements—from small cold rooms to large-scale industrial freezing warehouses.

Proven R&D Strength: Backed by rigorous testing and engineering expertise, our screw compressors comply with international standards (GB/T19410-2018) and are trusted by industrial operators worldwide.

Global Refrigerant Compatibility: Compatible with common industrial refrigerants (R134a, R404A, R507A, NH₃), ensuring seamless integration with existing systems.

Long-Term Reliability: Precision engineering and high-quality components guarantee a long service life, reducing replacement and maintenance costs over time.

Blait’s High-Efficiency Industrial Screw Refrigeration Compressor is a professional-grade solution engineered for demanding commercial and industrial cooling and freezing applications. Designed with a robust semi-hermetic structure and advanced screw rotor technology, this compressor delivers stable performance, energy savings, and long service life—making it ideal for cold storage, food processing facilities, industrial refrigeration plants, and heavy-duty freezing systems. Whether operating under high-pressure or low-temperature conditions, it maintains superior cooling capacity while minimizing energy consumption, addressing the core needs of businesses seeking reliable and cost-effective refrigeration solutions.

Optimized screw rotor profiles (YZ57 tooth profile line, composed of arcs and higher-order curves) and advanced motor technology work in tandem to reduce power consumption without compromising cooling output. The compressor’s minimized leakage triangle area and high area utilization coefficient (0.41 & 0.45) further enhance energy efficiency, cutting operational costs significantly.

The semi-hermetic design allows internal inspection and component access without full system shutdown, reducing downtime and maintenance complexity. Built with industrial-grade materials resistant to wear, corrosion, and high pressure, it ensures durability even in harsh industrial environments.

Engineered for smooth performance, this industrial screw compressor features low vibration and noise levels, making it suitable for sensitive settings such as food processing facilities and pharmaceutical cold storage where quiet operation is critical.

Supports both high and low-temperature applications (-50℃ to 20℃) for flexible system integration. The adjustable capacity function enables precise control over refrigeration output, improving part-load efficiency and adapting to variable load conditions seamlessly.

Tailored Industrial Solutions: Blait offers OEM and customized compressor specifications, including voltage, power, and installation accessories, to match unique project requirements—from small cold rooms to large-scale industrial freezing warehouses.

Proven R&D Strength: Backed by rigorous testing and engineering expertise, our screw compressors comply with international standards (GB/T19410-2018) and are trusted by industrial operators worldwide.

Global Refrigerant Compatibility: Compatible with common industrial refrigerants (R134a, R404A, R507A, NH₃), ensuring seamless integration with existing systems.

Long-Term Reliability: Precision engineering and high-quality components guarantee a long service life, reducing replacement and maintenance costs over time.

| Parameter | Value |

|---|---|

| Product Name | Energy-Saving Screw Compressor |

| Model | YLG20Z-84 screw compressor |

| Lubrication Method | Lubricated |

| Cooling System | Air-cooled |

| Power Source | AC |

| Structure Type | Semi-hermetic |

| Installation Type | Mobile |

| Type | Single-screw compressor |

| Displacement | 0.8-1.2 m³/min |

| Power | 7.5 kW |

| Compression Stage | Single-stage |

| Lubricant Capacity | 12 liters |

| Cooling Method | Air-cooling/Water-cooling |

| Voltage | 380V/50Hz |

| Minimum Order Quantity | 1 set/unit |

| Drive Method | Direct drive |

| Oil-free Type | Yes |

| Power Range | 4 kW to 355 kW |

| Origin | China |

The Energy-Saving Variable Speed Screw Compressor by Blait is engineered for industrial use. The YLG20Z-84 model is a reliable, single-stage compressor. Its direct drive system ensures efficient and smooth operation.

This compressor operates with a displacement of 0.8-1.2 m³/min, ideal for various industrial needs. It features a semi-hermetic structure and supports both air-cooling and water-cooling.

With a power capacity of 7.5 kW and a voltage requirement of 380V/50Hz, it delivers consistent performance. The lubrication method supports smooth operation with 12 liters of lubricant.

This model offers flexibility with its mobile installation type. Its oil-free design provides clean operation, suitable for demanding applications.

The power range from 4 kW to 355 kW makes it adaptable to various industrial setups. With a minimum order quantity of 1 unit, Blait ensures accessibility for businesses of all sizes.

Blait's screw compressors are designed for durability and energy efficiency, delivering reliable results for industrial applications.

| Technical Parameter | Description |

|---|---|

| Product Model | YLG20Z-84 ~ YLG30Z-118 |

| Tooth Profile Line | YZ57, composed of arcs and higher-order curves |

| Temperature Sensor | Standard PTC110°C |

| High-Pressure Working Conditions | Pressure difference resistance of 2.0MPa |

| Protection Module | Standard INT69 FSY protection module |

| Area Utilization Coefficient | 0.41 & 0.45 |

| Oil Flow Monitoring | Equipped with oil flow switch and monitoring of oil circulation as standard |

| Leakage Triangle Area | Smaller than conventional wires, reducing leakage losses effectively |

| Engine Displacement (50Hz) | 84m³/h ~ 118m³/h |

| Engine Displacement (60Hz) | 101m³/h ~ 142m³/h |

The Variable Speed Screw Compressor by Blait is an innovative solution for diverse industrial needs. Models range from YLG20Z-84 to YLG30Z-118, featuring an advanced YZ57 tooth profile line for optimized performance. Equipped with a PTC110°C temperature sensor and INT69 FSY protection module, it ensures safety and reliability under high-pressure conditions (up to 2.0MPa). A high area utilization coefficient (0.41 & 0.45) and minimized leakage triangle area enhance energy efficiency. With engine displacement of 84m³/h to 118m³/h (50Hz) and 101m³/h to 142m³/h (60Hz), plus standard oil flow monitoring, this compressor is durable, efficient, and ideal for demanding applications.

Dimensional Drawings:

Suction, Exhaust Valve Connector

| MODEL | YLG20Z-84 | YLG25Z-100 | YLG30Z-118 |

| SL | φ54(21/8") | φ54(2 1/8") | φ54(2 1/8") |

| DL | φ42(13/8") | φ42(1 3/8") | φ42(1 3/8") |

Application Scope lcon

Performance Parameter Table (R22)

Freqency 50 Hz

Based on 10 degree suction superheat;

and liquid re-cooling (Economiser operation)

| Compressor type | Cond temp(℃) | Qo(kw) Pe(kW) | Cooling capacity Qo (kw) Power consumption Pe (kW) | |||||||

| Evaporating temperatue (C ) | ||||||||||

| -10 | -15 | -20 | -25 | -30 | -35 | -40 | -45 | |||

| YLG20Z-84 | 30 | Qo | 61.9 | 51.9 | 43.4 | 35.9 | 29.3 | 23.5 | 18.4 | 14.1 |

| Pe | 19.4 | 18.5 | 16.9 | 16.6 | 15.8 | 15.2 | 14.6 | 13.9 | ||

| 40 | Qo | 59.1 | 49.5 | 41.3 | 34 | 27.6 | 21.9 | 17.1 | 12.8 | |

| Pe | 23.2 | 22.2 | 21.3 | 20.5 | 19.7 | 19.2 | 18.3 | 17.4 | ||

| 50 | Qo | 55.1 | 46.3 | 38.4 | 31.4 | 25.2 | 19.8 | 15 | ||

| Pe | 27.8 | 26.8 | 26.2 | 25.3 | 24.5 | 23.2 | 21.8 | |||

| YLG25Z-100 | 30 | Qo | 71.4 | 60.6 | 50.9 | 42.3 | 34.7 | 28 | 22.2 | 17.2 |

| Pe | 22.2 | 21.3 | 20.5 | 19.8 | 18.6 | 17.9 | 17.2 | 16.6 | ||

| 40 | Qo | 68.7 | 58.1 | 48.6 | 40.3 | 32.8 | 26.4 | 20.7 | 15.8 | |

| Pe | 26.5 | 25.4 | 24.5 | 23.6 | 22.7 | 21.8 | 20.9 | 20.1 | ||

| 50 | Qo | 65.1 | 54.9 | 45.7 | 37.5 | 30.3 | 23.9 | 18.4 | ||

| Pe | 31.8 | 30.7 | 29.5 | 28.6 | 27.7 | 26.1 | 25 | |||

| YLG30Z-118 | 30 | Qo | 83.1 | 70.5 | 59.3 | 49.4 | 40.6 | 32.8 | 26.1 | 20.2 |

| Pe | 25.9 | 24.7 | 23.5 | 22.4 | 21.4 | 20.5 | 19.6 | 18.8 | ||

| 40 | Qo | 79.9 | 67.6 | 56.7 | 47 | 38.5 | 30.9 | 24.4 | 18.7 | |

| Pe | 30.5 | 29.3 | 28.2 | 27.1 | 26 | 25.1 | 23.9 | 22.8 | ||

| 50 | Qo | 75.2 | 63.6 | 53.1 | 43.8 | 35.5 | 28.2 | 21.8 | ||

| Pe | 36.5 | 35.6 | 33.9 | 32.6 | 31.5 | 30.3 | 28.7 | |||

Performance Parameter Table (R404A/R507A)

Freqency 50 Hz

Based on 10 degree suction superheat;

and liquid re-cooling (Economiser operation)

| Compressor type | Cond temp(℃) | Qo(kw) Pe(kW) | Cooling capacity Qo (kw) Power consumption Pe (kW) | ||||||

| Evaporating temperatue (C ) | |||||||||

| -15 | -20 | -25 | -30 | -35 | -40 | -45 | |||

| YLG20Z-84 | 30 | Qo | 56.8 | 47.9 | 40 | 33 | 26.8 | 21.4 | 16.7 |

| Pe | 22.6 | 22.1 | 21.4 | 20.7 | 19.7 | 18.6 | 18 | ||

| 40 | Qo | 53.7 | 53.7 | 37.5 | 30.7 | 24.7 | 19.5 | 14.9 | |

| Pe | 28.3 | 28.3 | 26.8 | 25.8 | 24.7 | 23.5 | 21.9 | ||

| 50 | Qo | 34.2 | 27.1 | 21.6 | 16.5 | 11.9 | |||

| Pe | 32.1 | 30.9 | 29.5 | 28.5 | 26.3 | ||||

| YLG25Z-100 | 30 | Qo | 66.3 | 55.9 | 46.7 | 38.5 | 31.3 | 25.1 | 19.6 |

| Pe | 25.3 | 24.5 | 23.8 | 22.9 | 22.5 | 21.2 | 20.3 | ||

| 40 | Qo | 62.6 | 52.7 | 43.9 | 36 | 29.1 | 23 | 17.7 | |

| Pe | 31.8 | 31.2 | 28.8 | 29.2 | 28.2 | 26.5 | 24.8 | ||

| 50 | Qo | 42.6 | 33.7 | 25.7 | 19.8 | 14.6 | |||

| Pe | 40.2 | 37.7 | 34.8 | 32.6 | 30.2 | ||||

| YLG30Z-118 | 30 | Qo | 75.6 | 63.9 | 53.4 | 44.1 | 36 | 28.9 | 22.7 |

| Pe | 29.1 | 28.1 | 27.2 | 26.3 | 24.9 | 24.1 | 22.8 | ||

| 40 | Qo | 71.4 | 60.3 | 50.3 | 41.5 | 33.8 | 26.9 | 21 | |

| Pe | 36.2 | 35.2 | 33.8 | 32.8 | 31.2 | 30 | 28.5 | ||

| 50 | Qo | 46.2 | 38 | 30.8 | 24 | 18.3 | |||

| Pe | 41.5 | 40.1 | 38.4 | 37.7 | 35.2 | ||||

Technical Data Sheet

| Compressor type | Displacement (50Hz) | Displacement (60Hz) | Discharge pipe | Suction pipe | Energy regulation | Power supply | Maximumoperating current | Maximumpower | Start/locked rotor current | Weight |

| m³/h | mm (inch) | % | V/φ/Hz | A | kW | A | kg | |||

| YLG20Z-84 | 84 | 101 | φ42(15/8") | φ54(21/8") | 100/90/55 | 400±10% △/△△3~/50HZ 460±10% △/△△3~/60HZ Part Winding | 48 | 29 | 129/210 | 166 |

| YLG30G-84 | 84 | 101 | 100/90/70 | 52 | 33 | 126/218 | 170 | |||

| YLG25Z-100 | 100 | 121 | 100/80/45 | 52 | 33 | 126/218 | 169 | |||

| YLG35G-100 | 100 | 121 | 100/85/60 | 58 | 37.3 | 153/266 | 178 | |||

| YLG30Z-118 | 118 | 142 | 100/75/45 | 58 | 37 | 153/266 | 174 | |||

| YLG40G-118 | 118 | 142 | 100/80/55 | 66 | 42 | 182/311 | 183 | |||

| Parameter | Value |

|---|---|

| Product Name | Energy-Saving Screw Compressor |

| Model | YLG20Z-84 screw compressor |

| Lubrication Method | Lubricated |

| Cooling System | Air-cooled |

| Power Source | AC |

| Structure Type | Semi-hermetic |

| Installation Type | Mobile |

| Type | Single-screw compressor |

| Displacement | 0.8-1.2 m³/min |

| Power | 7.5 kW |

| Compression Stage | Single-stage |

| Lubricant Capacity | 12 liters |

| Cooling Method | Air-cooling/Water-cooling |

| Voltage | 380V/50Hz |

| Minimum Order Quantity | 1 set/unit |

| Drive Method | Direct drive |

| Oil-free Type | Yes |

| Power Range | 4 kW to 355 kW |

| Origin | China |

The Energy-Saving Variable Speed Screw Compressor by Blait is engineered for industrial use. The YLG20Z-84 model is a reliable, single-stage compressor. Its direct drive system ensures efficient and smooth operation.

This compressor operates with a displacement of 0.8-1.2 m³/min, ideal for various industrial needs. It features a semi-hermetic structure and supports both air-cooling and water-cooling.

With a power capacity of 7.5 kW and a voltage requirement of 380V/50Hz, it delivers consistent performance. The lubrication method supports smooth operation with 12 liters of lubricant.

This model offers flexibility with its mobile installation type. Its oil-free design provides clean operation, suitable for demanding applications.

The power range from 4 kW to 355 kW makes it adaptable to various industrial setups. With a minimum order quantity of 1 unit, Blait ensures accessibility for businesses of all sizes.

Blait's screw compressors are designed for durability and energy efficiency, delivering reliable results for industrial applications.

| Technical Parameter | Description |

|---|---|

| Product Model | YLG20Z-84 ~ YLG30Z-118 |

| Tooth Profile Line | YZ57, composed of arcs and higher-order curves |

| Temperature Sensor | Standard PTC110°C |

| High-Pressure Working Conditions | Pressure difference resistance of 2.0MPa |

| Protection Module | Standard INT69 FSY protection module |

| Area Utilization Coefficient | 0.41 & 0.45 |

| Oil Flow Monitoring | Equipped with oil flow switch and monitoring of oil circulation as standard |

| Leakage Triangle Area | Smaller than conventional wires, reducing leakage losses effectively |

| Engine Displacement (50Hz) | 84m³/h ~ 118m³/h |

| Engine Displacement (60Hz) | 101m³/h ~ 142m³/h |

The Variable Speed Screw Compressor by Blait is an innovative solution for diverse industrial needs. Models range from YLG20Z-84 to YLG30Z-118, featuring an advanced YZ57 tooth profile line for optimized performance. Equipped with a PTC110°C temperature sensor and INT69 FSY protection module, it ensures safety and reliability under high-pressure conditions (up to 2.0MPa). A high area utilization coefficient (0.41 & 0.45) and minimized leakage triangle area enhance energy efficiency. With engine displacement of 84m³/h to 118m³/h (50Hz) and 101m³/h to 142m³/h (60Hz), plus standard oil flow monitoring, this compressor is durable, efficient, and ideal for demanding applications.

Dimensional Drawings:

Suction, Exhaust Valve Connector

| MODEL | YLG20Z-84 | YLG25Z-100 | YLG30Z-118 |

| SL | φ54(21/8") | φ54(2 1/8") | φ54(2 1/8") |

| DL | φ42(13/8") | φ42(1 3/8") | φ42(1 3/8") |

Application Scope lcon

Performance Parameter Table (R22)

Freqency 50 Hz

Based on 10 degree suction superheat;

and liquid re-cooling (Economiser operation)

| Compressor type | Cond temp(℃) | Qo(kw) Pe(kW) | Cooling capacity Qo (kw) Power consumption Pe (kW) | |||||||

| Evaporating temperatue (C ) | ||||||||||

| -10 | -15 | -20 | -25 | -30 | -35 | -40 | -45 | |||

| YLG20Z-84 | 30 | Qo | 61.9 | 51.9 | 43.4 | 35.9 | 29.3 | 23.5 | 18.4 | 14.1 |

| Pe | 19.4 | 18.5 | 16.9 | 16.6 | 15.8 | 15.2 | 14.6 | 13.9 | ||

| 40 | Qo | 59.1 | 49.5 | 41.3 | 34 | 27.6 | 21.9 | 17.1 | 12.8 | |

| Pe | 23.2 | 22.2 | 21.3 | 20.5 | 19.7 | 19.2 | 18.3 | 17.4 | ||

| 50 | Qo | 55.1 | 46.3 | 38.4 | 31.4 | 25.2 | 19.8 | 15 | ||

| Pe | 27.8 | 26.8 | 26.2 | 25.3 | 24.5 | 23.2 | 21.8 | |||

| YLG25Z-100 | 30 | Qo | 71.4 | 60.6 | 50.9 | 42.3 | 34.7 | 28 | 22.2 | 17.2 |

| Pe | 22.2 | 21.3 | 20.5 | 19.8 | 18.6 | 17.9 | 17.2 | 16.6 | ||

| 40 | Qo | 68.7 | 58.1 | 48.6 | 40.3 | 32.8 | 26.4 | 20.7 | 15.8 | |

| Pe | 26.5 | 25.4 | 24.5 | 23.6 | 22.7 | 21.8 | 20.9 | 20.1 | ||

| 50 | Qo | 65.1 | 54.9 | 45.7 | 37.5 | 30.3 | 23.9 | 18.4 | ||

| Pe | 31.8 | 30.7 | 29.5 | 28.6 | 27.7 | 26.1 | 25 | |||

| YLG30Z-118 | 30 | Qo | 83.1 | 70.5 | 59.3 | 49.4 | 40.6 | 32.8 | 26.1 | 20.2 |

| Pe | 25.9 | 24.7 | 23.5 | 22.4 | 21.4 | 20.5 | 19.6 | 18.8 | ||

| 40 | Qo | 79.9 | 67.6 | 56.7 | 47 | 38.5 | 30.9 | 24.4 | 18.7 | |

| Pe | 30.5 | 29.3 | 28.2 | 27.1 | 26 | 25.1 | 23.9 | 22.8 | ||

| 50 | Qo | 75.2 | 63.6 | 53.1 | 43.8 | 35.5 | 28.2 | 21.8 | ||

| Pe | 36.5 | 35.6 | 33.9 | 32.6 | 31.5 | 30.3 | 28.7 | |||

Performance Parameter Table (R404A/R507A)

Freqency 50 Hz

Based on 10 degree suction superheat;

and liquid re-cooling (Economiser operation)

| Compressor type | Cond temp(℃) | Qo(kw) Pe(kW) | Cooling capacity Qo (kw) Power consumption Pe (kW) | ||||||

| Evaporating temperatue (C ) | |||||||||

| -15 | -20 | -25 | -30 | -35 | -40 | -45 | |||

| YLG20Z-84 | 30 | Qo | 56.8 | 47.9 | 40 | 33 | 26.8 | 21.4 | 16.7 |

| Pe | 22.6 | 22.1 | 21.4 | 20.7 | 19.7 | 18.6 | 18 | ||

| 40 | Qo | 53.7 | 53.7 | 37.5 | 30.7 | 24.7 | 19.5 | 14.9 | |

| Pe | 28.3 | 28.3 | 26.8 | 25.8 | 24.7 | 23.5 | 21.9 | ||

| 50 | Qo | 34.2 | 27.1 | 21.6 | 16.5 | 11.9 | |||

| Pe | 32.1 | 30.9 | 29.5 | 28.5 | 26.3 | ||||

| YLG25Z-100 | 30 | Qo | 66.3 | 55.9 | 46.7 | 38.5 | 31.3 | 25.1 | 19.6 |

| Pe | 25.3 | 24.5 | 23.8 | 22.9 | 22.5 | 21.2 | 20.3 | ||

| 40 | Qo | 62.6 | 52.7 | 43.9 | 36 | 29.1 | 23 | 17.7 | |

| Pe | 31.8 | 31.2 | 28.8 | 29.2 | 28.2 | 26.5 | 24.8 | ||

| 50 | Qo | 42.6 | 33.7 | 25.7 | 19.8 | 14.6 | |||

| Pe | 40.2 | 37.7 | 34.8 | 32.6 | 30.2 | ||||

| YLG30Z-118 | 30 | Qo | 75.6 | 63.9 | 53.4 | 44.1 | 36 | 28.9 | 22.7 |

| Pe | 29.1 | 28.1 | 27.2 | 26.3 | 24.9 | 24.1 | 22.8 | ||

| 40 | Qo | 71.4 | 60.3 | 50.3 | 41.5 | 33.8 | 26.9 | 21 | |

| Pe | 36.2 | 35.2 | 33.8 | 32.8 | 31.2 | 30 | 28.5 | ||

| 50 | Qo | 46.2 | 38 | 30.8 | 24 | 18.3 | |||

| Pe | 41.5 | 40.1 | 38.4 | 37.7 | 35.2 | ||||

Technical Data Sheet

| Compressor type | Displacement (50Hz) | Displacement (60Hz) | Discharge pipe | Suction pipe | Energy regulation | Power supply | Maximumoperating current | Maximumpower | Start/locked rotor current | Weight |

| m³/h | mm (inch) | % | V/φ/Hz | A | kW | A | kg | |||

| YLG20Z-84 | 84 | 101 | φ42(15/8") | φ54(21/8") | 100/90/55 | 400±10% △/△△3~/50HZ 460±10% △/△△3~/60HZ Part Winding | 48 | 29 | 129/210 | 166 |

| YLG30G-84 | 84 | 101 | 100/90/70 | 52 | 33 | 126/218 | 170 | |||

| YLG25Z-100 | 100 | 121 | 100/80/45 | 52 | 33 | 126/218 | 169 | |||

| YLG35G-100 | 100 | 121 | 100/85/60 | 58 | 37.3 | 153/266 | 178 | |||

| YLG30Z-118 | 118 | 142 | 100/75/45 | 58 | 37 | 153/266 | 174 | |||

| YLG40G-118 | 118 | 142 | 100/80/55 | 66 | 42 | 182/311 | 183 | |||

Delivers reliable low-temperature performance for preserving food, pharmaceuticals, and industrial goods, maintaining stable temperatures even in large-scale facilities.

Ensures product quality during processing and storage with precise temperature control, ideal for dairy processing, beverage cooling, and meat/poultry freezing.

Supports heavy-duty cooling for factories, chemical plants, and processing facilities, operating continuously under demanding load conditions.

Suitable for supermarkets, cold chain logistics, and large-scale refrigeration systems, adapting to varying commercial refrigeration needs.

Delivers reliable low-temperature performance for preserving food, pharmaceuticals, and industrial goods, maintaining stable temperatures even in large-scale facilities.

Ensures product quality during processing and storage with precise temperature control, ideal for dairy processing, beverage cooling, and meat/poultry freezing.

Supports heavy-duty cooling for factories, chemical plants, and processing facilities, operating continuously under demanding load conditions.

Suitable for supermarkets, cold chain logistics, and large-scale refrigeration systems, adapting to varying commercial refrigeration needs.

Regularly check lubricant levels (12 liters capacity) and replace every 1,000 operating hours.

Clean or replace air filters and oil filters quarterly to ensure optimal airflow and lubrication.

Inspect suction/exhaust valves and oil flow switches annually for leaks or malfunctions.

Compressor Warranty: 12 months from the date of installation, covering manufacturing defects.

Accessories & Parts: Replacement for quality-related issues within the warranty period.

Technical Support: Remote installation guidance, troubleshooting assistance, and wiring diagrams provided upon request.

Regularly check lubricant levels (12 liters capacity) and replace every 1,000 operating hours.

Clean or replace air filters and oil filters quarterly to ensure optimal airflow and lubrication.

Inspect suction/exhaust valves and oil flow switches annually for leaks or malfunctions.

Compressor Warranty: 12 months from the date of installation, covering manufacturing defects.

Accessories & Parts: Replacement for quality-related issues within the warranty period.

Technical Support: Remote installation guidance, troubleshooting assistance, and wiring diagrams provided upon request.

No products found