Call Us

+86-18072289720

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-09 Origin: Site

An electric motor is a machine that turns electrical power into spinning power. This is explained by engineering rules. You see this happen when you turn on a fan. You also see it when a toy car moves. When you give electricity to an electric motor, it uses magnets and wires to make things move. This easy process helps electric motors use about half of all electricity in the world. They power many things you use every day.

Electric motors turn electrical energy into movement. They power things like fans, toys, and cars.

The main parts of an electric motor are the rotor and the stator. The rotor spins. The stator makes a magnetic field. This field helps the rotor turn.

Electric motors use magnetic fields and electric current. These create a force that spins the rotor. This force also makes torque.

AC motors use alternating current. They are common in home appliances. DC motors use direct current. They give better speed control.

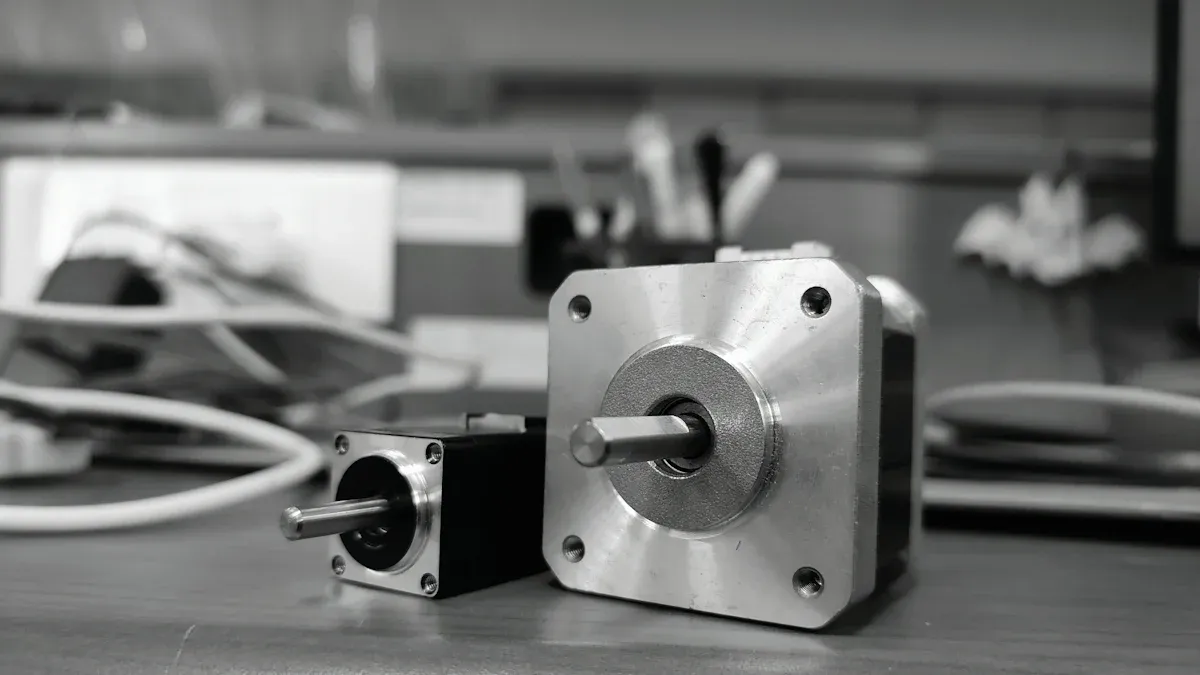

Some motors, like stepper and servo motors, give very exact control. People use them in robotics, 3D printers, and remote-controlled devices.

Electric motors save energy and lower pollution. They run quietly. This makes them good for the environment and saves money over time.

Some motors need care, like brushed DC motors. Brushless motors last longer and need less care.

Electric motors are used everywhere. They are in homes, factories, and transportation. They make life easier, cleaner, and more efficient.

You use an electric motor when you turn on a fan or start a toy car. The main job of an electric motor is to change electrical energy into movement. It takes electricity and makes things move. When electricity goes into the motor, it travels through coils of wire inside a magnetic field. This makes a force that spins the motor. In DC motors, commutators and brushes help switch the current’s direction. This keeps the motor spinning the same way, so it moves smoothly. You can see this energy change in many things, like kitchen tools and electric cars.

All electric motors have important parts that work together to make things move. The two main parts are the rotor and the stator. The rotor spins and gives power to what the motor moves. The stator does not move and makes the magnetic field for the rotor. The air gap between the rotor and stator helps the magnetic field work well. Some motors also have commutators, windings, and permanent magnets. These parts help control electricity and the magnetic field’s strength.

Here is a quick look at the main components and what they do:

| Component | Primary Function |

|---|---|

| Rotor | Rotating part that turns the shaft to deliver mechanical power |

| Stator | Generates the magnetic field necessary to rotate the rotor |

| Bearings | Support the rotor shaft |

| Bracket/End Plate | Supports the bearings and stator |

| Lead Wires | Connect the motor to the power supply |

| Commutator | Reverses current direction in some motor types |

| Windings | Create magnetic fields for electromagnetic induction |

| Air Gap | Ensures efficient magnetic interaction between rotor and stator |

| Core | Provides a path for magnetic flux, made of iron or silicon steel |

| Insulator | Prevents unwanted current flow |

| Permanent Magnets | Generate magnetic fields in certain motors |

Electric motors work because of electromagnetic induction. When electricity goes through the windings, it makes a magnetic field. The stator makes its own magnetic field too. The rotor spins inside the stator and interacts with this field. The moving charges in the wires feel a push from the magnetic field. This push makes the rotor turn. The way the force pushes depends on the current and the magnetic field. You can use the right-hand rule to find out which way the force goes.

Magnetic fields only push on moving charges.

The force is always at a right angle to the current and the magnetic field.

The force gets stronger with more current, a stronger magnetic field, or a bigger angle.

This force makes the rotor spin and turns electrical energy into movement.

The Laplace force, also called the Lorentz force, is why motors spin. When current moves through the rotor’s wires, the stator’s magnetic field pushes on the charges. This push is always at a right angle to the current and the magnetic field. This creates a twisting force called torque. Torque is what makes the rotor turn. The amount of torque depends on the magnetic field’s strength, the current, and the rotor’s size. The stator and rotor magnetic fields work together to make torque. This lets electric motors do work in things like power tools and electric cars.

You can understand how electric motors work by looking at what happens inside. When you turn on the power, electrical current flows into the motor. This current moves through coils of wire, usually found in the stator. As the current flows, it creates a magnetic field around the coils. The rotor, which sits inside the stator, also has its own magnetic field. Sometimes, the rotor uses permanent magnets. Other times, it uses coils that make a magnetic field when current passes through them.

The magic happens when these two magnetic fields interact. The magnetic field from the stator pushes and pulls on the magnetic field in the rotor. This push and pull creates a force. The force acts on the rotor and makes it spin. You see this principle of operation in every electric motor, from the smallest toy to the biggest industrial machine.

Tip: The direction of the force always depends on the direction of the current and the magnetic field. You can use the "right-hand rule" to figure out which way the rotor will turn.

If you want the rotor to keep spinning, you need to keep changing the direction of the current. In many electric motors, a part called the commutator helps with this job. The commutator switches the current in the rotor windings at just the right moment. This keeps the magnetic fields pushing and pulling in the right way, so the rotor never gets stuck. In brushless motors, electronic controllers do the switching instead of a commutator.

Without current reversal, the rotor would stop after half a turn. By reversing the current at the right time, the motor keeps spinning smoothly. This is why electric motors can run fans, pumps, and even electric cars for hours without stopping.

Think about how you ride a bicycle. When you push the pedals, you make the wheels turn. In an electric motor, electricity acts like your legs, and the magnetic fields act like the pedals. The current gives energy to the coils, and the magnetic fields push the rotor, just like your legs push the pedals.

Let’s break down how electric motors work step by step:

You turn on the power, and current flows into the stator coils.

The stator coils create a magnetic field.

The rotor, with its own magnetic field, sits inside the stator.

The two magnetic fields interact and create a force.

This force applies torque to the rotor, making it spin.

The rotor spins on its shaft, turning electrical energy into mechanical energy.

In some motors, a commutator or electronic controller reverses the current to keep the rotor spinning.

The spinning shaft can power anything from a fan blade to a car wheel.

Note: The speed of the motor depends on how fast the magnetic field switches direction. Faster switching means faster spinning.

You can see the principle of operation in action every time you use a blender, a washing machine, or an electric scooter. Electric motors make life easier by turning electricity into useful motion.

The rotor is like the heart of the motor. It sits inside and spins when you turn on the power. The spinning rotor connects to a shaft. This shaft moves things, like a fan or a car wheel. The rotor has conductors, such as copper or aluminum bars. These bars work with the magnetic field from the stator. This teamwork creates torque, which is the force that turns the rotor. The rotor’s core is made from thin steel sheets called laminations. Laminations help stop energy loss and make the motor work better. Some rotors use permanent magnets. Others use coils of wire. Materials like copper, aluminum, and steel make the rotor strong and help it last a long time.

The rotor is attached to a shaft in the center of the motor. This shaft lets the rotor spin easily. It also sends the spinning motion to the thing you want to move. Bearings hold up the shaft and help it turn with less friction. The rotor’s size and shape change depending on the motor’s job.

Tip: A smaller air gap between the rotor and stator makes the magnetic connection stronger and helps the motor work better.

The stator is the outer shell of the motor. It does not move while the rotor spins inside. The stator has coils of wire called windings. These windings carry electricity. They wrap around a core made from thin iron or steel sheets. The stator’s job is to make a strong magnetic field when current flows through the coils.

When you turn on the motor, electricity goes through the stator windings. This makes a magnetic field that reaches across the air gap to the rotor. The stator’s magnetic field pushes and pulls on the rotor to make it spin. The stator’s core, made from silicon steel laminations, helps guide the magnetic field and stops energy loss. The stator is important because it starts the process that makes the motor work.

Here is a table showing how some main parts of an electric motor help it work:

| Part | Contribution to Motor Function |

|---|---|

| Stator | Stays still and has coils that make a magnetic field to start the rotor moving. |

| Rotor | Spins to give power; works with the stator’s magnetic field to make torque. |

| Bearings | Hold up the rotor and shaft, help them turn smoothly, and lower friction. |

| Windings | Coils that make magnetic poles when powered, so the magnetic fields can work together. |

| Air Gap | Space between rotor and stator; a smaller gap means better performance and less wasted power. |

Most DC motors have commutators and brushes. The commutator is a special part on the rotor’s shaft. It looks like a ring made of copper pieces. Brushes are usually made of carbon. They press against the commutator and stay still while the commutator spins.

The commutator works like a switch. It changes the direction of the current in the rotor windings every half turn. This keeps the torque pushing the rotor the same way, so the motor spins smoothly. The brushes keep touching the spinning commutator. This makes sure the current flows at the right time. Without the commutator and brushes, the motor would stop and start instead of spinning well.

The commutator changes the current flow in the rotor every half turn.

Brushes touch the commutator to switch connections.

This system keeps the motor spinning one way and stops it from stalling.

All these important electric motor parts work together to turn electrical energy into movement. Each part has a special job. Together, they help the motor run smoothly and do its work well.

An electric motor needs a power supply to work. The power supply gives energy to the motor. This energy helps turn electricity into movement. There are two main types of power supplies for electric motors. These are alternating current (AC) and direct current (DC).

AC power comes from wall outlets at home or school. The current in AC power changes direction very quickly. In the United States, it switches direction 60 times each second. This is called 60 hertz (Hz). When you use an AC motor, the changing current helps the motor spin. The motor does not need extra parts to switch the current. The AC power supply does this job for you. This makes AC motors simple and easy to use.

DC power comes from batteries or special devices that change AC to DC. DC current only flows in one direction. If you use a DC motor, you need a way to reverse the current inside. The commutator, which is a key electric motor part, does this job. It switches the current’s direction every half turn. This keeps the rotor spinning the same way. Without this switching, the rotor would stop after half a turn.

You can see the main differences between AC and DC motors in the table below:

| Aspect | AC Motors | DC Motors |

|---|---|---|

| Power Supply | Powered by alternating current (single or three phase) | Powered by direct current (from batteries or rectified AC) |

| Operation | Rotor speed synchronized with AC frequency; electromagnetic field in stator causes rotation | Uses commutator to reverse current direction every half turn to maintain torque in one direction |

| Speed Control | Controlled by varying AC frequency using Variable Frequency Drives (VFDs) | Controlled by varying DC voltage; allows precise speed control |

| Efficiency | Three-phase induction motors efficient at high power and speed | Brushless DC motors efficient over broad range; brushed DC less efficient due to brushes |

| Maintenance | Generally low maintenance, especially brushless types | Brushed DC motors require frequent brush and commutator servicing |

| Cost | Cost-effective for large, constant speed/load applications | Higher initial cost for brushless DC; lifetime cost comparable to AC |

| Starting Torque | Lower starting torque; may require starting devices | High starting torque enabling quick acceleration |

| Applications | Household appliances, pumps, HVAC, industrial machinery | Mobile applications, robotics, electric vehicles, conveyor systems, precision equipment |

You should pick the right power supply for your motor’s job. For fans or washing machines, you will probably use an AC motor. For robots or electric cars, you will often use a DC motor. Each power supply works with different electric motor parts to help the motor run well.

Tip: Always check what kind of power supply your motor needs before you use it. Using the wrong power supply can break the motor or make it stop working.

You can find many types of electric motors in the world around you. Each type works in a special way and fits different jobs. You can group electric motors by the kind of power they use and how they are built. Here is a simple list to help you see the main categories:

AC Motors: These run on alternating current from outlets.

DC Motors: These use direct current from batteries or power supplies.

Special Purpose Motors: These include stepper motors and other unique designs.

Let’s look at each group and see how they work.

AC electric motors use the changing direction of current from wall outlets. You see these motors in many home and industrial machines. There are two main types of AC motors: induction and synchronous.

Induction motors are the most common type of AC motor. You use them in fans, washing machines, and pumps. These motors do not need any special parts to start spinning. The stator creates a rotating magnetic field. The rotor follows this field and starts to spin. Induction motors are strong and last a long time. You do not need to do much to keep them working.

Key features:

Simple design

Low maintenance

Good for constant speed jobs

Synchronous motors spin at the same speed as the magnetic field in the stator. You find these motors in places where you need steady speed, like clocks or conveyor belts. Synchronous motors use extra parts, such as slip rings or permanent magnets, to keep the rotor in sync with the stator’s field.

Synchronous motors give you precise speed control. They work best when you need the motor to turn at a set rate.

DC motors use direct current. You get this current from batteries or special power supplies. There are two main types of DC motors: brushed and brushless.

Brushed DC motors use brushes and a commutator to switch the current in the rotor. You find these motors in toys, small tools, and car starters. Brushed motors are easy to control. You can change their speed by changing the voltage.

Pros:

Simple to use

Good for jobs that need quick starts

Cons:

Brushes wear out over time

Need more maintenance

Brushless DC motors do not use brushes. Instead, they use electronic parts to switch the current. These motors last longer and run more quietly than brushed motors. You see brushless motors in drones, computers, and electric cars.

Brushless motors give you high efficiency and less noise. You do not need to replace brushes, so they last longer.

Stepper motors are special purpose motors. You use them when you need precise control of movement. Stepper motors move in small steps instead of spinning smoothly. Each step moves the shaft a set amount. You find stepper motors in 3D printers, CNC machines, and robots.

| Motor Type | Defining Characteristics | Typical Applications |

|---|---|---|

| AC Motors | Continuous motion, speed set by frequency | Fans, conveyors, pumps |

| DC Motors | Speed set by voltage, brushed or brushless | Toys, tools, electric vehicles |

| Stepper Motors | Moves in steps, holds position without feedback | 3D printers, CNC, robotics |

You can see that the types of electric motors each have their own strengths. When you pick a motor, think about the job you need it to do. Some motors work best for steady speed. Others give you fine control or quick starts.

Servo motors help you control movement with high precision. You often find them in robots, remote-controlled cars, and even in some home appliances. When you need something to move to a specific position and stop, a servo motor is the right choice.

A servo motor uses a small electric motor, a set of gears, and a control circuit. The control circuit tells the motor how far to turn and when to stop. You send a signal to the servo, and it moves the shaft to the exact angle you want. The motor holds that position until you tell it to move again.

Tip: If you want to move something to a certain spot and keep it there, use a servo motor. It will not drift or lose its place.

You control a servo motor with a special signal called a pulse. The length of the pulse tells the motor what angle to move to. For example, a short pulse might move the shaft to 0 degrees. A longer pulse might move it to 90 or 180 degrees. The servo checks the signal many times each second. If the shaft is not in the right spot, the motor turns until it matches the signal.

Servo motors use feedback to stay accurate. Inside the servo, a sensor checks the shaft’s position. If the shaft moves away from the target angle, the control circuit sends power to the motor to correct it. This feedback loop keeps the shaft steady.

You see servo motors in many places:

Robotics: Servos move robot arms and legs to exact spots.

RC Vehicles: They steer wheels or control flaps in cars, boats, and planes.

Cameras: Servos adjust the lens or move the camera for smooth shots.

Printers: They move the print head to the right place on the page.

| Application | What the Servo Does |

|---|---|

| Robot Arm | Moves joints to set positions |

| RC Car | Turns wheels for steering |

| Camera Gimbal | Keeps camera steady and level |

| 3D Printer | Moves print head for accuracy |

You pick a servo motor when you need control, speed, and accuracy. Servos can move fast, but they also stop exactly where you want. They use less power than some other motors because they only work when needed. You can find servo motors in many sizes, from tiny ones in toys to large ones in factory machines.

Note: Servo motors are different from stepper motors. Steppers move in steps, but servos use feedback for smooth, precise motion.

If you want to build a robot, control a camera, or move something to a set spot, a servo motor gives you the control you need.

You find AC motors in many home and factory machines. These motors use alternating current. This means the current changes direction many times each second. When you turn on the power, the stator makes a spinning magnetic field. This field moves around inside the motor. The rotor sits inside and follows the spinning field. The changing magnetic field in the stator makes a current in the rotor. This current makes the rotor spin.

AC motors do not need brushes or a commutator. The alternating current creates the spinning magnetic field by itself. This helps the motor run quietly and smoothly. There are fewer parts that wear out, so you get less maintenance and a longer life. The speed of an AC motor depends on the power supply’s frequency and the number of poles in the motor. If you want to change the speed, you can use a variable frequency drive.

AC motors are brushless, so you do not need to replace brushes or worry about extra friction.

Here is a quick comparison of AC and DC motor operation:

| Feature | AC Motor | DC Motor |

|---|---|---|

| Power Source | Alternating Current (AC) | Direct Current (DC) |

| Commutation | No mechanical commutator | Uses commutator and brushes |

| Maintenance | Low | Higher (due to brushes) |

| Speed Control | By frequency and voltage | By voltage or field current |

DC motors work in a different way than AC motors. They use direct current, which only flows one way. Inside a DC motor, you find a commutator and brushes. The commutator is a split ring on the rotor. Brushes press against the commutator and send current to the rotor windings. As the rotor turns, the commutator switches the current’s direction in the windings. This keeps the rotor spinning the same way.

DC motors let you control speed and torque very well. You can change the speed by changing the voltage or the field current. These motors give strong starting torque, so they are good for things that need a fast start or careful speed control. But the brushes and commutator wear out after some time. You need to check and replace them.

If you want steady and exact speed control, a DC motor is a good pick. Just remember to take care of the brushes for smooth running.

Stepper motors are different from other electric motors. They move in steps, not in a smooth spin. You control a stepper motor by sending electrical pulses to the stator coils. Each pulse makes a magnetic field that pulls the rotor to a new spot. The rotor lines up with the magnetic field, moving one step at a time.

You can change the direction by changing the order of the pulses. Stepper motors have many stator and rotor parts, so you get lots of steps in one turn. This lets you move the shaft to a very exact angle. You do not need extra sensors for position because the motor moves just as you tell it.

Stepper motors work well in:

3D printers

CNC machines

Robotic arms

Printers and scanners

Stepper motors give you very accurate position control. You can move to any angle you want, one step at a time.

You use stepper motors when you need to move something to a certain spot and keep it there. The step-by-step movement makes them great for jobs that need precision.

You often use servo motors when you need precise control over movement. These motors help you move things to exact positions and hold them there. You find servo motors in robots, remote-controlled cars, and even in some home appliances. When you want something to move to a specific angle and stop, a servo motor gives you that control.

A servo motor has three main parts: a small electric motor, a set of gears, and a control circuit. The control circuit receives a signal from a controller. This signal tells the servo motor how far to turn. The gears slow down the motor and increase its strength. This lets the servo move heavy objects with accuracy.

You control a servo motor with a special signal called a pulse. The length of the pulse tells the servo what angle to move to. For example, a short pulse might move the shaft to 0 degrees. A longer pulse could move it to 90 or 180 degrees. The servo checks this signal many times each second. If the shaft is not in the right spot, the control circuit sends power to the motor until it matches the signal.

Tip: Servo motors use feedback to stay accurate. Inside the servo, a sensor checks the shaft’s position. If the shaft moves away from the target angle, the control circuit corrects it right away.

You can see how this works in a simple example. Imagine you want to move a robot arm to pick up a block. You send a signal to the servo motor. The control circuit reads the signal and turns the shaft to the right angle. The feedback sensor checks the position. If the arm is not in the right place, the motor keeps turning until it is perfect. The servo then holds the arm steady until you send a new signal.

Here is a quick list of where you might use servo motors:

Robot arms and legs

Steering in RC cars and planes

Camera gimbals for smooth video

Printers and 3D printers for moving parts

Servo motors stand out because they can move fast and stop exactly where you want. They use less power than some other motors because they only work when needed. You can find servo motors in many sizes, from tiny ones in toys to large ones in factory machines.

The operation of a servo motor always depends on the control signal and the feedback system. This combination gives you the power to move things with speed and accuracy.

Electric motors are in many things at home. They help your appliances work well and stay quiet. A brushless DC motor keeps your fridge cold. This motor is fast and does not make much noise. Motors in ovens move air so food heats evenly. Washing machines use universal motors for strong spinning. Vacuum cleaners need powerful motors to suck up dirt. Dishwashers use high-voltage DC motors to pump water and clean dishes.

Here is a table that shows how appliances use electric motors:

| Household Appliance | Common Electric Motor Types Used | Key Application Details |

|---|---|---|

| Refrigerator | Brushless DC motors (BLDC) | Quiet, efficient, high-speed cooling |

| Oven | Brushless DC, AC motors | Circulate heat, precise control |

| Washing Machine | Universal, Shaded-pole motors | High torque, strong spin cycles |

| Vacuum Cleaner | Universal motors (series DC) | High speed, strong suction |

| Dishwasher | High-voltage DC, Inverter motors | Power pumps, energy savings |

Electric motors power almost every big appliance at home. These motors make chores easier and faster for you.

Electric motors have changed how people travel. You find them in cars, buses, trains, and even planes. Electric trains use motors powered by wires, batteries, or hydrogen fuel cells. These trains are quiet and do not pollute the air. New electric planes, like NASA’s X-57 and Eviation’s Alice, use many motors for smooth flight. Some companies are testing hydrogen planes for the future.

You also see electric motors in other vehicles:

Electric cars and trucks use motors for clean, quiet driving.

City buses run on electric power to cut pollution.

Trains use motors for fast, reliable trips.

Boats and ships use motors to steer and move.

Airplanes use motors for engines and small jobs inside.

Electric motors make travel cleaner, quieter, and more reliable. You get smoother rides and less pollution.

Factories and businesses need electric motors for many jobs. Motors power machines that build things, move stuff, and pack goods. In factories, motors run conveyor belts, robotic arms, and pumps. Motors help weld, paint, and process food. You can pick different motors for each job. DC motors give steady speed and easy control. AC motors are good for heavy work. Servo motors help robots move with precision. Stepper motors let machines move in small, exact steps.

Modern factories use smart motor control systems. These systems use sensors and computers to watch motors. They help save energy and keep machines safe. If a motor has a problem, sensors warn you early. This helps you fix things before they break and stop work.

Tip: Picking the right electric motor saves energy, lowers costs, and helps your factory work better.

Electric motors are important for making things you use every day. They help factories work faster, safer, and with better quality.

You use electric motors all the time, even if you do not notice. These small machines help many things in your home and neighborhood work well. Electric motors make life easier, safer, and more comfortable for you.

Many home appliances have electric motors inside. When you turn on a fan, the motor spins the blades to move air. If you use a blender or food processor, the motor turns sharp blades to chop and mix food fast. Your washing machine uses a motor to spin the drum or agitator. This helps clean your clothes with strong, steady movement. In your refrigerator, a motor runs the compressor. This keeps your food cold and fresh. When you vacuum the floor, the motor spins a fan inside to make suction.

Here are some devices that need electric motors:

Electric fans

Blenders

Food processors

Washing machines

Refrigerators

Vacuum cleaners

Ceiling fans

Dishwashers

You also see electric motors working outside your house. Elevators and escalators use motors to move people between floors. Power window regulators in cars let you move windows up or down with a button. Electric cars use big motors to turn the wheels. This gives you a quiet and clean ride.

Tip: When you use an appliance, listen for a soft hum or whir. That sound is often from an electric motor doing its job.

You can see how different devices use electric motors in this table:

| Device | How the Motor Helps |

|---|---|

| Electric Fan | Spins blades to move air |

| Blender | Turns blades to chop and mix food |

| Washing Machine | Rotates drum or agitator to clean clothes |

| Refrigerator | Runs compressor to keep food cold |

| Vacuum Cleaner | Powers fan to create suction |

| Dishwasher | Drives pumps and spray arms for cleaning |

| Elevator | Lifts and lowers the cabin |

| Escalator | Moves steps for easy transport |

| Power Window | Raises and lowers car windows |

You need electric motors for many things you do every day. These motors save you time and hard work. They help you cook, clean, stay cool, and travel safely. If you look around, you will see electric motors power much of your world. You can see how these simple machines make your life better each day.

Electric motors give you many good things at home and in factories. They work very well and use most of the electricity to make things move. Most electric motors turn 80% to 95% of the power they get into motion. This is much better than engines that burn fuel, which only use about 20% to 30% of their energy. You save energy and spend less money over time.

Electric motors are also better for the environment. They do not make dirty air when running, so the air stays cleaner. You can use solar or wind power to run them, which is even better for the planet. In factories, using special motors and speed controls can cut energy use by up to 60%. This helps lower greenhouse gases and helps the world fight climate change.

You will see that electric motors are quiet. They make less noise than engines that burn fuel. This means your home, car, and city are quieter. Electric motors give full torque right away, so machines and cars start fast. Some electric vehicles use regenerative braking, which saves energy and helps brakes last longer.

It is easier to take care of electric motors because they have fewer moving parts. You do not need to fix them as often, so you save time and money. Electricity costs less than gas or diesel and does not change price as much. You can find electric motors in many sizes, from tiny ones in toys to big ones in trains. This means you can use them for almost any job.

Tip: Picking electric motors helps you use cleaner energy, save money, and get good, steady performance.

Here is a simple table that shows how electric motors help save energy and lower pollution in factories:

| Feature | Impact |

|---|---|

| High efficiency (up to 95%) | Saves energy and lowers costs |

| No local emissions | Improves air quality |

| Quiet operation | Reduces noise pollution |

| Variable speed drives | Cuts energy use by 25% to 60% |

| Renewable energy compatibility | Supports clean energy goals |

There are also some problems with electric motors you should know. One big problem is that electric vehicles cannot go as far as gas cars. Batteries do not hold as much energy, so you may need to stop and charge more often on long trips. There are not as many charging stations as gas stations, so travel can be harder in some places.

Charging takes longer than filling up with gas. You might have to wait 30 minutes or even a few hours, depending on the charger and battery. Electric motors and batteries cost more at first than regular engines. This makes electric vehicles and some machines more expensive to buy, even if you save money later.

Some electric motors, like brushed DC motors, need more care. The brushes and commutators wear out and must be replaced. In places with lots of dust or gas, brushed motors can make sparks, which is not safe. Brushless motors fix many of these problems, but they can cost more.

Making high-efficiency motors can also use rare earth materials and water. This can hurt the environment, but the energy you save while using the motor is usually more important than the impact from making it.

Note: The good and bad sides of electric motors depend on what you need and where you use them. Think about range, charging, cost, and care before you decide.

You use electric motors all the time, even if you do not see them. These machines change electricity into movement. They power things like fans and electric cars.

Electric motors help cut down on pollution. They also support clean energy and make devices work better and quieter.

You can find electric motors in homes, factories, and vehicles. They help make life easier and better for the planet.

If you look around your home or school, you will see electric motors in many appliances and machines. As technology gets better, motors will become smarter, smaller, and more eco-friendly.

An electric motor’s main job is to turn electricity into movement. The motor uses electrical energy to make things spin or move. You see this in fans, cars, and many home devices.

Yes! Electric motors are in blenders, washing machines, fans, and toothbrushes. Motors help these things work fast and easily.

You can hear a soft hum or whir when it runs. If something spins, moves, or shakes with power, it probably has an electric motor.

Most electric motors do not need much care. Brushless motors last longer and need less fixing. Brushed motors might need new brushes after some time.

AC motors use power from wall outlets. DC motors use batteries or special power supplies. AC motors are good for steady jobs. DC motors let you control speed better.

Electric motors are safe if you use them the right way. Always follow the instructions. Keep motors dry and away from water. Unplug devices before you clean or fix them.

Yes, you can change the speed. For AC motors, use a variable frequency drive. For DC motors, change the voltage or use a controller. This helps you set the speed you want.

No products found