Call Us

+86-13185543350

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-07 Origin: Site

The importance of compressors in heat pumps cannot be overstated, as the compressor is the main component that enables the heat pump to both heat and cool effectively. It works by moving and compressing the refrigerant, which allows heat to transfer more efficiently. When the compressor operates well, the refrigerant reaches higher pressures and temperatures, improving the overall performance of the system. Modern heat pumps with advanced compressors achieve high coefficients of performance (COP), sometimes exceeding 4. This means you receive more than four times the amount of heat compared to the electricity consumed, resulting in significant energy savings. Because of the importance of compressors in heat pumps, having a high-quality compressor reduces power consumption and enhances system efficiency, making heat pumps a superior choice over traditional heating and cooling methods.

Compressors play a crucial role in heat pumps. A reliable compressor uses less energy and boosts the system’s effectiveness.

The compressor is the main part of a heat pump. It moves and squeezes refrigerant to move heat. This helps with heating and cooling in your home.

A good compressor saves energy and makes your home more comfortable. It also lowers your electric bills by making the heat pump work better.

Scroll and rotary compressors are common in homes. They are quiet, work well, and use less energy.

Cleaning, changing filters, and getting check-ups help your compressor last longer. These steps keep it working well.

Compressor problems can show as odd noises or weak heating and cooling. You might also see higher bills or the system shutting off a lot.

Variable-speed compressors can change how fast they run. This matches your heating or cooling needs. It saves energy and keeps comfort steady.

New compressor designs make less noise and shake less. This makes heat pumps quieter and nicer to have at home.

Picking the right compressor for your home is important. Think about size, how well it works, noise, and your weather. This helps your heat pump last longer and work better.

You might wonder why the compressor is so important in a heat pump. The answer is simple: the compressor acts as the heart of the system. It keeps everything moving and makes heating and cooling possible. When you turn on your heat pump, the compressor starts working right away. It takes in cold, low-pressure refrigerant gas and squeezes it into a hot, high-pressure gas. This step is essential because it allows the refrigerant to release heat when it moves through the condenser.

Think of the compressor like a bicycle pump. When you push down on the pump, you force air into the tire, raising the pressure. The compressor does the same thing with refrigerant. By increasing the pressure, it helps the refrigerant absorb and release heat more efficiently. Without this process, your heat pump would not be able to move heat from one place to another.

HVAC experts call the compressor the "heart" of the heat pump because it drives the entire system. It uses the most electricity and works the hardest. If the compressor stops working, the whole system fails. You will notice higher energy bills, less comfort, and poor heating or cooling. The importance of compressors in heat pumps cannot be ignored. They make heat transfer possible and keep your home comfortable all year.

Tip: Keep your compressor in good shape with regular maintenance. This helps your heat pump run smoothly and saves you money.

In a typical home, the compressor sits between the indoor evaporator and the outdoor condenser. It keeps the refrigerant moving through the system. The importance of compressors in heat pumps shows up every time you need to heat or cool your home. The compressor makes sure the refrigerant absorbs heat from the outside air, even when it is cold, and releases it inside.

Let’s look at a real-life example. Imagine you live in a cold area. One winter, your heat pump struggles to keep your house warm. A technician checks the system and finds the compressor is not building enough pressure. The refrigerant moves too slowly, so not enough heat gets inside. After replacing the compressor, your home feels warm again, even on freezing days.

The compressor in heat pumps must keep the refrigerant at the right pressure and temperature. This allows the system to work well, no matter the weather. If the compressor fails, you will see higher energy use, less comfort, and more repairs. The importance of compressors in heat pumps means you should always pay attention to how your system runs. Regular check-ups and quick repairs help your compressor last longer and keep your home comfortable.

Diagram Suggestion:

Picture a simple drawing. The compressor is in the middle, like a heart. Arrows show refrigerant moving from the evaporator to the compressor, then to the condenser, and then through the expansion valve back to the evaporator. This loop keeps your heat pump working.

The compressor works like the heart of your heat pump. It acts as a pump that keeps things moving. Your heart pushes blood through your body. The compressor pushes refrigerant through the system. This movement lets the heat pump move heat from one place to another. When the compressor runs, it pulls refrigerant from the evaporator and sends it to the condenser. Without this flow, your heat pump cannot heat or cool. If the compressor stops, the refrigerant will not move. You might see your system running but not changing the temperature. Sometimes, you may hear odd sounds or see the heat pump turn off. In these cases, you need a professional to check the compressor.

The main job of the compressor is to squeeze the refrigerant gas. When refrigerant enters the compressor, it is a low-pressure, low-temperature gas. The compressor squeezes this gas, making it higher in pressure and temperature. This step is very important. By raising the pressure, the compressor gives the refrigerant enough energy to release heat in the condenser. In modern heat pump systems, this squeezing increases the heat in the refrigerant. The compressor gets the refrigerant ready for the next stage, where it can release or take in heat as needed. If the compressor cannot squeeze the refrigerant, the heat pump will not work well. You may notice poor performance and higher energy bills.

The heat exchange process depends on the compressor. Here is how it works:

1. The compressor takes in low-pressure, low-temperature refrigerant gas from the evaporator. 2. It squeezes the gas, turning it into a high-pressure, high-temperature gas. 3. The hot gas moves to the condenser, where it releases heat and becomes a liquid. 4. The liquid refrigerant goes through the expansion valve, dropping in pressure and temperature. 5. The cold refrigerant returns to the evaporator, ready to take in heat again.

This cycle repeats every time your heat pump runs. The compressor makes this process work, so your home stays comfortable. If the compressor fails, the heat pump cannot move heat. You lose both heating and cooling. Regular maintenance helps keep the compressor working well and your heat pump running smoothly.

When you look inside a heat pump, you will see different compressor types. Each type works best for certain jobs. The most common are scroll compressors and rotary compressors. Some heat pumps use other types, like reciprocating or screw compressors. These are used in bigger or special systems.

Here is a table that shows where each compressor type is used and some market trends:

Compressor Type | Typical Application | Market Share / Trend Highlights (2024) |

|---|---|---|

Scroll | Residential | Favored for compact design and quiet operation; common in residential heat pumps. |

Screw | Commercial & Industrial | Used in high capacity, efficiency-demanding commercial/industrial applications. |

Reciprocating | Small to medium scale | Versatile use in small to medium applications. |

Centrifugal | Large scale | Suited for large-scale settings. |

Rotary (Single Rotary) | Residential & Light Commercial | Holds largest revenue share in rotary compressor market in 2024; dominant in residential applications. |

Rotary (Twin Rotary) | High-end Residential & Commercial | Fastest growing segment; energy-efficient, low noise; gaining traction in commercial applications. |

Scroll compressors are often found in home heat pumps. They have two spiral-shaped parts that move in circles. This design makes them small and quiet. You can put a scroll compressor in small spaces. It also makes less noise in your house.

Advantages of scroll compressors:

Small size fits in many places.

Fewer moving parts mean less maintenance.

High energy efficiency helps lower your power bills.

Quiet operation is great for bedrooms or living rooms.

Long lifespan with fewer repair needs.

Disadvantages:

Higher upfront cost than piston compressors.

Not good for very high flow rates or large amounts of liquid refrigerant.

Output pressure can change, so they may not work for every job.

Note: Scroll compressors give steady, warm air and use less energy than old designs. You might pay more at first, but you save money later.

Rotary compressors are also popular in heat pumps for homes and small businesses. They use a spinning part to squeeze the refrigerant. This gives you steady air and good performance.

Here is a quick comparison between rotary and reciprocating compressors:

Aspect | Rotary Compressors | Reciprocating Compressors |

|---|---|---|

Efficiency | Higher in continuous use; fewer moving parts; steady air output | Better for short bursts; less efficient in long use |

Reliability | More durable; longer lifespan (up to 20 years); less maintenance needed | Needs more repairs; shorter lifespan (about 10 years) |

Noise Level | Quieter, good for homes | Louder, better for outdoor or industrial use |

Cost | Higher at first, but saves money over time | Cheaper to buy, but costs more to maintain |

You will see rotary compressors in most air source heat pumps. These compressors help your system run quietly and efficiently. They also last a long time, so you do not have to worry about frequent repairs.

Some heat pumps use other compressor types. Reciprocating compressors use pistons to move refrigerant. These work well in small or medium systems but need more maintenance. Screw compressors use two spiral screws and are best for big commercial or industrial heat pumps. Centrifugal compressors use a spinning part and are found in very large systems, like district heating.

New ideas are changing how compressors work. For example, variable-speed scroll compressors can change their speed to match your heating or cooling needs. This saves energy and keeps your home comfortable, even when the weather changes. Some new compressors use special refrigerants that are better for the environment and work well in cold places.

Tip: When you pick a heat pump, ask about the compressor type. The right compressor can make your system quieter, more efficient, and last longer.

You want your heat pump to use less energy. It should still keep your home comfortable. The compressor is very important for this. When it works well, it moves refrigerant from low to high pressure and temperature. This helps your heat pump give out more heat than the electricity it uses. If the compressor does not work well, your heat pump needs more energy. This makes the system less efficient and raises your bills.

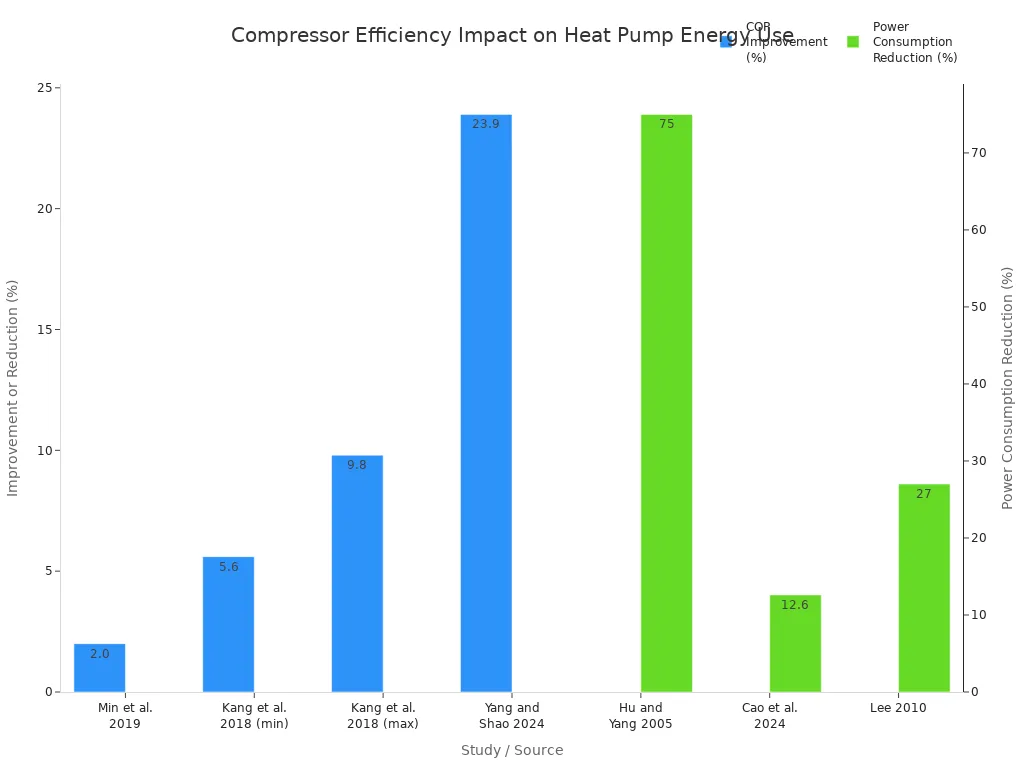

If compressors get old or you skip maintenance, they lose efficiency. Studies show poor care or a bad compressor can lower efficiency by up to 30%. This means your heat pump will not work as well. You will also pay more money. But if you take care of your compressor, the coefficient of performance (COP) stays high. COP tells you how much heat you get for each unit of electricity. A better compressor means a higher COP. This is important for saving energy at home.

Capacity means how much heating or cooling your heat pump can give. The compressor controls this amount. When the compressor runs faster, it gives more heating or cooling. If you need more heat on a cold day, the compressor speeds up. This gives you more warmth. The faster the compressor goes, the more heat it gives. But it also uses more energy.

Your heat pump cannot go too low or too high in output. The compressor must keep a minimum speed to stay safe. If it goes too slow, refrigerant and oil may not flow right. This can hurt the system. System design and software help control these limits. Even small heat pumps have a minimum output. They cannot always run at very low levels. This keeps your system safe and working well.

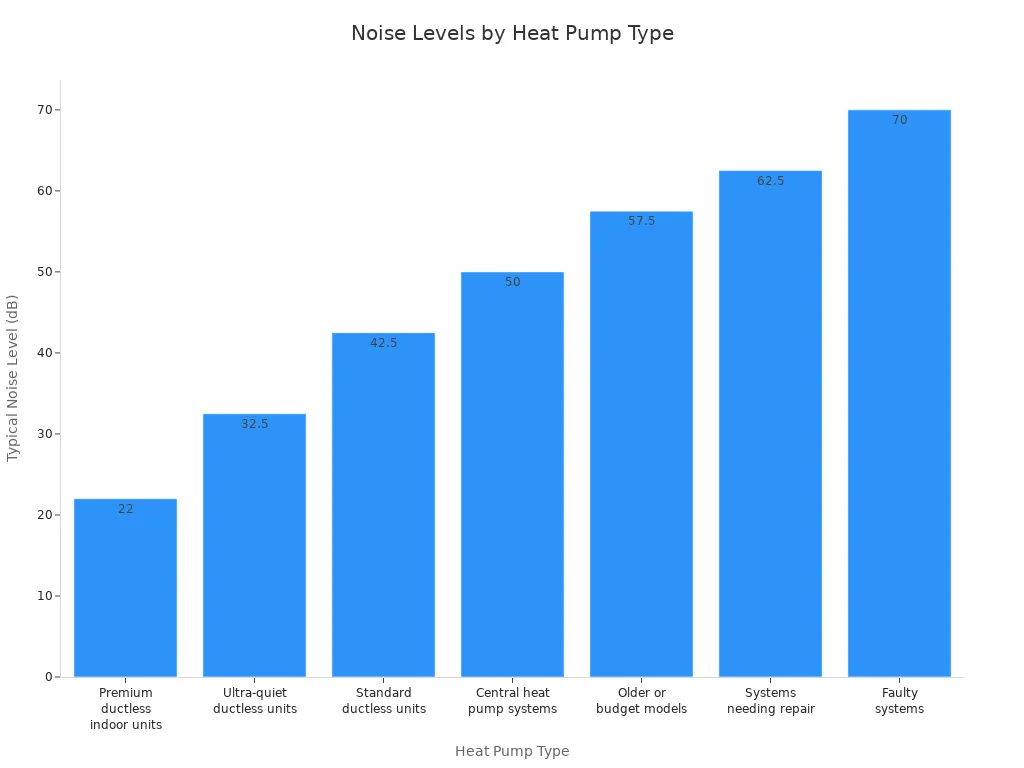

Noise and vibration are important for comfort at home. The compressor makes most of the sound in a heat pump. Some systems are very quiet. Others can be loud, especially if they are old or broken. Ductless mini-split heat pumps are the quietest. Their indoor units can be as low as 19-35 decibels (dB). This is softer than a whisper. Central heat pump systems are usually 45-55 dB. This is about as loud as a normal talk. Old or broken systems can reach 60 dB or more. This can be annoying.

Heat Pump Type | Typical Noise Level (dB) | Real-World Sound Comparison |

|---|---|---|

Premium ductless indoor units | 19-25 | Whisper, rustling leaves |

Ultra-quiet ductless units | 30-35 | Quiet library, soft whisper |

Standard ductless units | 40-45 | Quiet office, refrigerator hum |

Central heat pump systems | 45-55 | Normal conversation, moderate rainfall |

Older or budget models | 55-60 | Background music, dishwasher |

Systems needing repair | 60-65 | Busy restaurant, normal TV volume |

Faulty systems | 70+ | Vacuum cleaner, city traffic |

Good installation helps lower noise and vibration. You can use anti-vibration pads. You can also put the unit away from bedrooms or living rooms. Premium brands add special features to make heat pumps quieter. If you hear new or loud sounds, your compressor may need help. Keeping your system in good shape helps you enjoy quiet and comfortable heat pump performance.

When you choose a heat pump for your home, you want it to work well every day. Reliability means your system keeps running without breaking down. The compressor plays a big part in this. If your compressor works well, your heat pump will last longer and need fewer repairs.

A reliable compressor helps your heat pump handle different weather. On cold winter nights or hot summer days, the compressor must keep working. If it fails, your heat pump cannot move heat. You might notice your house feels too cold or too hot. Sometimes, the system will not turn on at all. That is why you should pay attention to how your heat pump sounds and works.

Here are some signs that show your heat pump is reliable:

It starts up quickly and runs smoothly.

You do not hear loud or strange noises from the outdoor unit.

The system keeps your home at the right temperature.

You do not see sudden spikes in your energy bills.

The heat pump does not need repairs often.

Tip: Schedule regular check-ups for your heat pump. A technician can spot small problems before they become big ones.

The design of the compressor affects reliability. Scroll compressors and rotary compressors have fewer moving parts. This means they break down less often. Older types, like reciprocating compressors, have more parts that can wear out. If you want a system that lasts, look for a heat pump with a modern compressor.

You can also help your heat pump last longer by following these steps:

Keep the outdoor unit clean and free of leaves or dirt.

Change or clean the air filters every few months.

Make sure the area around the heat pump stays clear.

Listen for new noises and call a technician if you hear anything strange.

Get a professional to check the refrigerant level once a year.

Here is a quick table to help you see what affects reliability:

Factor | Impact on Reliability |

|---|---|

Compressor type | Fewer moving parts = more reliable |

Regular maintenance | Prevents breakdowns |

Clean surroundings | Reduces wear and tear |

Proper installation | Ensures smooth operation |

If you take care of your heat pump, it will take care of you. A reliable system gives you comfort and peace of mind all year.

When you pick a compressor for your heat pump, you need to think about a few key things. The right compressor helps your system work well and last longer.

Always look at the energy efficiency rating. Compressors with higher ratings use less power and save you money. Some tools, like Danfoss COMPASS, let you put in details like refrigerant type and temperature. These tools help you find compressors that work best and have a high coefficient of performance (COP). This means you get more heating or cooling for each dollar you spend.

Make sure the compressor fits your heat pump system. The refrigerant type, supply temperature, and system setup must all match. If you use the wrong compressor, your system might not work right or could break down early.

Size is important. If the compressor is too big, your heat pump will turn on and off a lot. This wastes energy and wears out parts faster. If it is too small, your system will have trouble keeping your home comfortable. Doing the right load calculations helps you avoid these problems.

Some compressors are quiet, but others are loud. If you want a quiet home, pick models with low noise ratings. Scroll and rotary compressors are usually quieter than older ones.

Pick a compressor from a brand people trust. Good brands give strong warranties and better support. This helps you feel safe if something goes wrong.

Your local weather matters when picking a compressor. In places with big temperature changes, variable-speed compressors help keep your home comfy and efficient. In very cold areas, scroll compressors with refrigerant injection can give more heat and work better, even when it is freezing outside.

Taking care of your compressor helps your heat pump work well and last longer.

You should have regular inspections. A technician can find small problems before they get worse.

Keep the outdoor unit clean. Take away leaves, dirt, and other junk. This helps air move and stops overheating.

Low or high refrigerant levels can hurt your compressor. Have a professional check and fix them if needed.

Change or clean your air filters every few months. Clean filters help your system breathe and work better.

Get a professional to service your system once a year. Regular maintenance can help your heat pump last up to 20 years or more.

Tip: Good maintenance stops breakdowns and saves you money on repairs.

Look out for these warning signs. They often mean your compressor needs help.

Loud banging, rattling, or hissing sounds are not normal. These noises can mean something is wrong inside.

If your home feels less comfy or you notice weak airflow, your compressor may be having trouble.

If your energy bill suddenly goes up, your compressor might be working too hard.

If your system will not start or keeps turning off, the compressor could be the problem.

If your system turns on and off a lot or trips breakers, your compressor is under stress. Call a professional right away if you see these problems.

Note: Finding problems early and fixing them fast can stop big breakdowns and keep your heat pump working well.

Variable-speed compressors have changed how heat pumps work. They help you feel more comfortable and save energy. Old compressors only turn on or off. Variable-speed compressors can go faster or slower. This matches how much heating or cooling you need. Your heat pump does not waste energy by always running at full power.

Variable-speed compressors use inverter drives to change speed.

They give your home just the right amount of heating or cooling.

You get steady temperatures with fewer hot or cold spots.

The compressor starts gently, so parts last longer.

Your heat pump lasts longer because it avoids hard stops and starts.

The compressor is quieter because it runs slower most of the time.

These systems can use about 30% less energy than old ones.

You help the environment by making less greenhouse gas.

Variable-speed technology works in both warm and cold places. It uses smart sensors and controls to keep your home comfy and your bills low.

You want your heat pump to be quiet at home. New compressor designs help lower noise so you can relax. Companies use smart ideas to make compressors quieter.

Inverter-driven compressors change speed to make less noise.

Fans with special shapes make less air noise.

Vibration pads and rubber mounts stop shaking from reaching your house.

Soundproofing inside the compressor blocks and absorbs noise.

Better refrigerant flow and special coatings help cut noise.

Technology Type | Description |

|---|---|

Mechanical Design Improvements | Balanced scroll compressors reduce vibration and noise. |

Vibration Isolation | Flexible hoses and mounts keep vibrations from spreading. |

Acoustic Noise Damping | Foam and barriers inside the unit absorb sound. |

Pulsation Noise Reduction | Larger discharge spaces lower pressure surges and noise. |

Mechanical Noise Reduction | Special valves and parts cut down on rattling and banging. |

Pressure Pulsation Damping | Expansion chambers smooth out pressure changes for quieter operation. |

Some companies use electric controls to shape the motor’s current. This lowers vibrations, which cause most of the noise. You get a quieter home without losing heating or cooling.

Compressor technology now helps you protect the planet. New features make heat pumps greener and more efficient.

Inverter-driven compressors save energy by running only as needed.

Cold climate heat pumps use two-stage and variable-speed compressors to work in freezing weather.

Vapor injection warms the refrigerant, making the system work better.

Electronic valves and sensors control refrigerant for top performance.

Modern heat pumps can reach up to 400% efficiency, even in cold places.

Modulated compressors let your heat pump work in more weather and use less energy.

Built-in diagnostics and protection make your system last longer and easier to fix.

Over 200 million scroll compressors are used around the world. This shows that eco-friendly compressor technology is now common. When you pick a heat pump with these features, you save money and help the planet.

You help your heat pump work its best. The compressor is the main part of your system. It helps your home stay comfortable and saves energy. Pick the right compressor for your heat pump. Clean the coils, change the filters, and get a pro to check it. These steps stop big repairs and keep your system working well. More people are buying heat pumps now. If you make smart choices and take care of your system, your home will stay comfy. Learn about new heat pump news and ask experts for advice.

You will find the compressor moves and squeezes the refrigerant. This action lets your heat pump move heat into or out of your home. The compressor makes heating and cooling possible.

You might hear loud noises, notice weak heating or cooling, or see higher energy bills. Sometimes, your heat pump will not start. If you see these signs, call a technician.

You should schedule a professional check-up once a year. Clean the outdoor unit and change filters every few months. Regular care helps your compressor last longer and work better.

Yes, you can replace only the compressor if it fails. A technician will check if the rest of your system works well. Sometimes, replacing the whole unit makes more sense if it is old.

Scroll and rotary compressors work best for most homes. They run quietly, use less energy, and last a long time. Ask your installer which type fits your needs.

Yes! Variable-speed compressors adjust their speed to match your needs. This feature helps you use less electricity and keeps your home more comfortable.

Most noise comes from the compressor. Some sounds are normal, like a gentle hum. Loud banging, rattling, or hissing means something is wrong. You should get it checked if you hear new or strange noises.

A well-maintained compressor can last 10 to 20 years. Regular cleaning and yearly check-ups help you reach the longest lifespan.

No products found