Call Us

+86-13185543350

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-03 Origin: Site

Have you ever wondered about the Accumulators role in preventing rotary compressor failures, especially when a compressor stops working even though it appears fine? An accumulator acts as a safeguard between your compressor and major issues like liquid slugging, oil migration, sudden pressure fluctuations, and contamination from dirt or debris. Understanding the Accumulators role in preventing rotary compressor failures is crucial. Neglecting their maintenance or skipping essential inspections can lead to costly repairs and equipment breakdowns.

Accumulators keep rotary compressors safe by blocking liquid refrigerant. This stops damage like liquid slugging from happening. They help keep oil inside the compressor. This saves energy and stops the equipment from wearing out. Accumulators have special shapes like cylinders and L tubes. These shapes help separate liquid from vapor. This keeps the system steady. Inside, screens catch dirt and metal pieces. This stops expensive damage to the compressor. Using accumulators helps compressors last longer. They lower stress on parts and stop sudden pressure changes. Checking and fixing accumulators often helps find problems early. This can stop costly repairs. Without accumulators, compressors can break more easily. They may leak and not cool well. Accumulators help the system work better. They make sure refrigerant flows smoothly and stop the compressor from turning on and off too much.

Liquid slugging is very dangerous for rotary compressors. This happens when liquid refrigerant gets inside the compressor instead of vapor. It usually happens during cold startup or when the system is not stable. When liquid slugging happens, pressure inside the compressor rises fast. It can go up to 2400 kPa. This quick pressure change puts stress on the compressor parts. It can cause the compressor to break.

Liquid slugging is more common with R290 refrigerant. This refrigerant makes slugging happen more easily. Other things, like fast compressor speed or low suction gas, also make slugging worse. If your system does not have an accumulator, slugging is more likely. This is true during startup and defrosting. The main result is serious damage. Parts like valves and pistons can break. Sometimes, the whole compressor can fail.

Tip: Check for liquid slugging signs during regular maintenance. Finding it early can stop expensive damage.

Oil migration is another reason compressors can fail. Oil can leave the compressor and move to other parts. When oil covers heat exchangers, it blocks heat from moving. This makes the compressor work harder and use more energy. Oil fouling can lower heat transfer by up to 35%. This makes the system less efficient by 15-30%. Over time, oil migration raises energy costs. It also makes equipment last less time and break down more.

You can stop oil migration with good filters and regular checks. Some new solutions, like special additives, help remove leaked oil. Keeping oil in the right place helps avoid compressor failure. It also keeps your equipment working well.

Pressure surges, or compressor surge, cause strong shaking inside the compressor. These surges happen when refrigerant flow is not steady. You might hear loud sounds or feel vibrations. Pressure gauges may move a lot. Surges can happen a few times a minute or up to 15 times a second.

Pressure surges can cause:

Blades or impellers to break

Damage to seals and bearings

Fast temperature rises near the compressor inlet

Pressure going up and down again and again

If you do not fix these problems, surges can destroy the compressor. Surge control and regular checks help stop these dangers. Sensors near the compressor outlet and special temperature sensors at the inlet can warn you early.

Here is a table that shows common causes of rotary compressor failure and what they do:

| Failure Cause | Description | Effects / Indicators |

|---|---|---|

| Lubrication Problems | Oil loss, oil mixing, wrong oil, foaming, thin oil | Temperature changes, crankshaft color changes, wear, piston stuck or broken |

| Contamination | Water, copper oxide, dirt from setup or oil changes | Rust, oxidation, chemical problems, jamming, breakdown |

| High Discharge Temperature | High compression, not enough refrigerant | Overheating, piston wear, carbon on valve plate, vane problems |

| Liquid Return | Refrigerant mixes with oil, oil film goes away | More vibration, clean parts with no oil, friction damage |

| Liquid Blowby | Liquid in chamber from valve problems or bad air flow | Suction valve damage, valve plate damage, rod or piston cracks, grooves, or breaks |

| Mechanical Failures | Cracks in impellers and blades from shaking and vibration | Blades break, dents, rods break, imbalance, more vibration |

Knowing these risks helps you act before the compressor fails. Regular checks, good maintenance, and using accumulators help keep your compressor safe.

Foreign particles can get into your compressor and cause trouble. You might not see them, but they can do a lot of harm. These particles come from many places and hurt your equipment in different ways.

You may find these foreign particles in compressor systems:

Nuts, bolts, and washers left after repairs

Gasket pieces from old seals

Debris from past breakdowns

Oil particles and sludge that build up

Ice made from water inside the system

These particles can get in because of bad air filters or cracked pipes. Sometimes, broken engine parts send debris into the system. Even tiny objects can cause big problems. For example, a small bolt once got past the inlet screen of a Honeywell LTS101 turboshaft engine. This little piece hurt the compressor blades. It showed that even strong screens cannot stop every object.

When these particles get inside, they can chip or pit metal parts. You might hear loud metal sounds if something hits the compressor wheel blades. Other damage includes broken blades, bent shafts, and hurt nozzle ring blades. If you lose power or hear odd sounds, foreign particles could be the reason.

A real test on a supercritical CO2 radial compressor showed how risky these particles are. In that test, 3 mm metal chips from welding got inside the compressor. The chips hurt the impeller section. This damage lowered the compression ratio and made the compressor work worse. The system was not safe until the problem was fixed.

Here are signs that foreign particles may be in your compressor:

Sudden loss of power

Strange vibrations or noises

Drop in compressor performance

Damage you can see during checks

Tip: Always look for loose parts and clean up before closing your compressor. Good air filters and regular checks help keep foreign particles out.

If you ignore these risks, you may have to pay for costly repairs or even lose your compressor. Keeping foreign particles out helps your compressor run well and saves you from downtime.

Most accumulators look like a cylinder. This shape is not just for style. The round body slows down the refrigerant flow. When refrigerant goes in, it spreads out inside. Heavy liquid falls to the bottom. Lighter vapor rises to the top. This stops liquid from rushing into the compressor. If liquid gets in, it can break the compressor. The cylinder shape also makes the accumulator strong. It can handle high pressure without bending.

Note: The size of the cylinder is planned. It holds enough liquid during sudden surges, like when starting up or defrosting.

Inside, there is an L-shaped tube. This tube moves vapor from the bottom to the outlet. If liquid gets in, the L tube gives it time to turn into vapor. The tube bends up, so only vapor goes through easily. Leftover liquid stays at the bottom until it becomes vapor. This keeps liquid slugging from hurting the compressor. Liquid slugging can break parts and stop your system.

At the bottom of the L tube is a small oil return hole. This hole lets oil go back to the compressor slowly. Oil helps the compressor parts move well. Without this hole, you could lose oil and have more breakdowns.

There are screens inside the accumulator. These screens act like guards. They catch dirt, metal chips, or gasket pieces. Even tiny things can cause big problems if they get inside. The screens stop the compressor from locking up or getting damaged. They also keep the refrigerant flow clean and steady.

Here is a table that shows how these features help:

| Feature | Purpose | How It Protects the Compressor |

|---|---|---|

| Cylindrical Shape | Slows and separates refrigerant | Stops liquid from entering compressor |

| L Tube Pathway | Guides vapor, allows liquid to vaporize | Prevents liquid slugging |

| Oil Return Hole | Returns oil to compressor | Maintains lubrication |

| Internal Screens | Blocks debris | Prevents internal damage |

Keeping these parts in good shape helps your system last longer and have fewer problems.

Accumulators help stop rotary compressor failures. When refrigerant goes into the accumulator, it slows down. The heavy liquid falls to the bottom. The lighter vapor rises up. Inside, a part like a bladder or diaphragm keeps gas and liquid apart. This helps the accumulator store energy and keep refrigerant in the right form. You should check the nitrogen gas pressure inside the accumulator. Gauges or sensors can help you do this. Keeping the pressure correct helps the accumulator work better and last longer.

A real test in a cooling system showed something important. A bigger accumulator made the system more stable and work better. The size and shape of the accumulator are important for separating liquid from vapor.

Accumulators are most helpful when they stop liquid slugging. If liquid refrigerant gets into the compressor, it can break parts. Flooding makes oil foam and raises crankcase pressure. You might see a cold crankcase, foamy oil, or low oil. The compressor may use more power and get too hot. The accumulator traps liquid and lets it turn into vapor before it reaches the compressor. This keeps your compressor safe and saves money on repairs.

Accumulators help stop:

Flooding and slugging

Oil foaming and losing lubrication

High crankcase pressure

Overheating and tripping

The L tube inside the accumulator is very important. It guides vapor up and out. Liquid stays at the bottom. The L tube gives leftover liquid time to turn into vapor. Only vapor goes to the compressor. This keeps the compressor safe and working well.

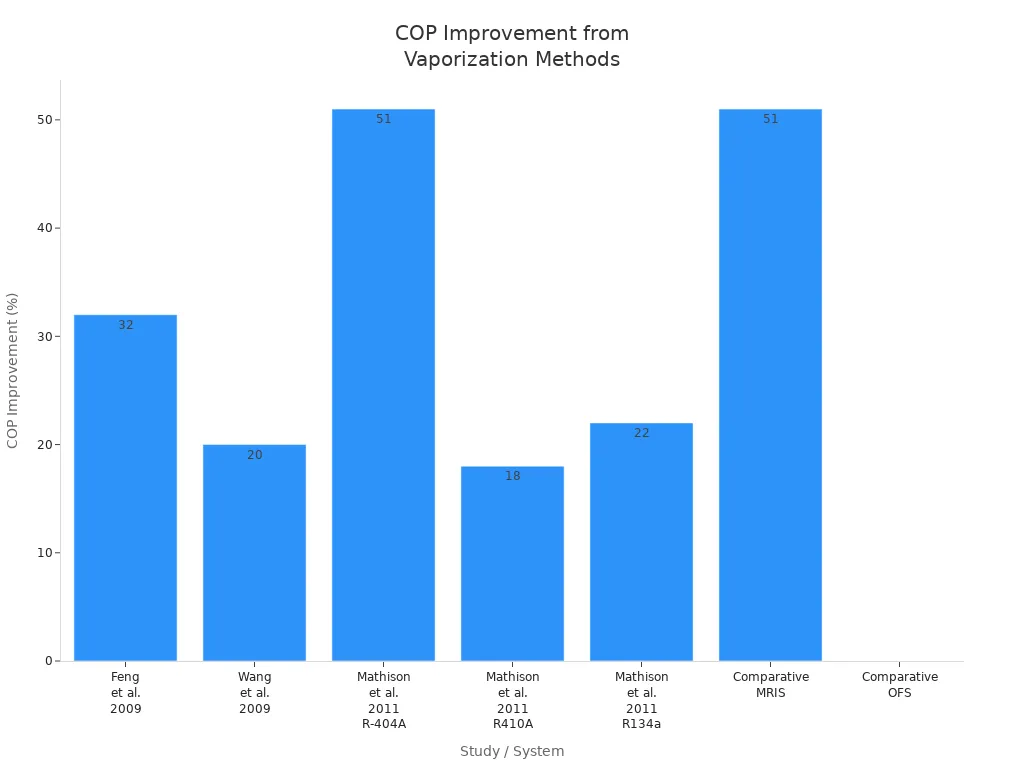

When vaporization happens before compression, the system works better. Studies show vapor injection and other ways can make heating and cooling up to 30% better. Efficiency can go up by over 50%. The chart below shows how different vaporization methods help:

Making sure only vapor goes to the compressor lowers heat and power use. This helps the compressor last longer and use less energy.

Compressor floodback happens when liquid gets into the compressor during normal use. Accumulators help by holding extra liquid. This keeps it away from the compressor. The accumulator keeps your system safe when there is too much liquid, like at startup or low load.

The accumulator also controls how refrigerant goes back to the compressor. Small holes let liquid and oil move back slowly and safely. This stops a sudden rush of liquid. Only vapor goes to the compressor. The accumulator protects your system and keeps it running well.

When you look inside an accumulator, you will find internal screens. These screens act like a filter for your system. They catch dirt, metal shavings, and other small objects before they can reach the compressor. If you let these particles pass through, they can cause serious problems. The screens use fine mesh material. This mesh traps even tiny pieces that you might not see with your eyes.

You can think of these screens as a safety net. They sit at the entry and exit points inside the accumulator. When refrigerant flows through, the screens stop unwanted debris. This process keeps the refrigerant clean. Clean refrigerant helps your compressor run smoothly and last longer.

Here are some things the screens can catch:

Metal chips from repairs or wear

Gasket fragments from old seals

Dust and dirt from the environment

Sludge or oil particles

Tip: Always check the screens during routine maintenance. If you see buildup, clean or replace the screens right away.

The screens inside the accumulator do more than just filter. They protect the most important parts of your compressor. When you keep particles out, you stop damage before it starts. Small objects can scratch, pit, or even break moving parts inside the compressor. Over time, this damage can lead to expensive repairs or total failure.

You will notice fewer breakdowns when you keep the screens in good shape. The compressor will run with less noise and vibration. You also lower the risk of sudden shutdowns. Clean screens mean the oil and refrigerant stay pure. This purity helps all moving parts work together without extra friction.

Here is a table that shows how screens protect your compressor:

| Problem Caused by Particles | How Screens Help | Result for Compressor |

|---|---|---|

| Scratched surfaces | Trap sharp debris | Less wear and tear |

| Blocked oil passages | Catch sludge and dirt | Better lubrication |

| Broken blades or valves | Stop large fragments | Fewer mechanical failures |

If you want your compressor to last, pay attention to the screens in your accumulator. This small step can save you time and money.

You want your compressor to last a long time. Accumulators help by taking in sudden pressure jumps. When the system gets a shock, the accumulator softens the blow. This keeps the compressor and other parts safe from harm. Less stress means less damage over time. You will see your compressor needs fewer fixes. It can run longer before needing service. By stopping these shocks, you make the service times farther apart. Your equipment keeps working well.

Liquid slugging can ruin a compressor very fast. If liquid refrigerant gets inside, it can break valves and pistons. Accumulators stop this by catching the liquid first. This keeps the compressor safe from sudden breakdowns. You do not have to pay for big repairs. This is very helpful during startup or when there is compressor floodback. Keeping liquid out stops damage and keeps your compressor safe.

Your compressor needs oil to work right. Accumulators help send oil back to the compressor slowly. This keeps all the moving parts oiled. When oil flows well, you do not lose lubrication. There is less friction and less heat inside. Good oil flow also stops compressor floodback. Floodback can wash away oil and cause harm. With enough oil, your compressor runs quietly and lasts longer.

Compressor floodback often causes emergency repairs. Too much liquid in the compressor can make it fail fast. Accumulators hold extra liquid and let it out as vapor. This stops compressor floodback and keeps your system running. You spend less time fixing things. Your system works better and does not break down by surprise.

When you protect your compressor from stress and liquid, you do not need new parts as much. Accumulators keep bad liquids and dirt away from important parts. You save money on new parts and have less downtime. Your maintenance is easier to plan.

Accumulators make checking your system easier. You can look at the accumulator for signs of floodback or dirt. If you find problems early, you can fix them before they get worse. Routine checks are faster and simpler. This helps keep your system in good shape.

Foreign particles can cause big trouble in your compressor. Accumulators use screens to catch dirt and metal pieces. This keeps your compressor safe from sudden failures. You avoid costly repairs and your system lasts longer.

Accumulators act like cushions in your system. They handle pressure changes and keep things steady. With an accumulator, you see fewer pressure swings. The compressor does not turn on and off as much. Your system holds steady pressure where you need it. You use less energy and protect your compressor from extra wear.

Benefits of steady operation include:

Better energy use

More steady pressure

Fewer compressor cycles

Longer life for your equipment

With an accumulator, you can spot problems early. If you see liquid or dirt in the accumulator, you know something is wrong. Finding issues early lets you fix them before a breakdown. You keep your compressor safe and avoid surprise downtime.

You want your rotary compressor to work well. Accumulators help by making refrigerant flow smooth. When refrigerant goes into the accumulator, it slows down. Heavy liquid falls to the bottom. Vapor rises to the top. This is called phase separation. It keeps liquid away from the compressor. Only vapor moves on to the next part.

Good phase separation stops problems like liquid slugging. The compressor does not get hit by sudden liquid bursts. This means less stress and more steady work. You get a smooth flow of refrigerant. This helps your compressor use energy better.

Tip: Good phase separation also keeps oil in the right place. This means less damage to moving parts and fewer breakdowns.

When your system works well, you save energy and money. Accumulators are important for this. They keep refrigerant in the right form. The compressor does not waste power. Only vapor goes into the compressor. It works less and uses less electricity.

Tests on rotary compressors show some big changes. The temperature inside the cylinder can drop by up to 7 °C. This makes volumetric efficiency go up by 3.5%. Electrical efficiency goes up by 4.4%. These results come from careful tests. The tests use special tools to measure cooling and power use.

You get these benefits because the compressor works easier. Lower temperatures mean less heat is lost. Your system cools faster and uses less energy. This helps lower your utility bills.

Starting and stopping too much can wear out your compressor. Accumulators help stop this problem. They control refrigerant flow and keep liquid away from the compressor. This makes the system run smoother. Your compressor cycles less often. This means less wear on its parts.

A system that cycles less lasts longer. You spend less time and money fixing it. You also avoid sudden breakdowns. With fewer cycles, your compressor stays in good shape. It gives you steady performance.

| Benefit | How Accumulators Help |

|---|---|

| Smoother refrigerant flow | Prevents liquid slugging |

| Better energy efficiency | Keeps vapor entering compressor |

| Less compressor cycling | Reduces wear and extends lifespan |

Keeping your accumulator in good shape helps your compressor work well every day.

You can find problems with the accumulator if you know what to check. When it fails, it cannot keep out moisture or dirt. This lets leaks happen in the refrigerant. You might hear odd sounds, like hissing or bubbling. These noises mean refrigerant could be leaking out. If your cooling feels weak, the accumulator may not work right. Poor cooling happens when refrigerant does not move well. Sometimes, the system can even freeze up.

A broken accumulator can also make bad smells. Moisture inside lets mold or mildew grow. If you smell something musty, look at the accumulator. High pressure in the system is another warning. When the accumulator gets clogged, pressure goes up. This can hurt the compressor and make cooling worse. If you ignore these signs, you could burn out the compressor and pay a lot for repairs.

Tip: If your A/C cools badly, makes weird sounds, or smells musty, check the accumulator first.

If you run a rotary compressor without an accumulator, you risk big problems. Without it, liquid refrigerant can get to the compressor. This causes liquid slugging, which can break valves and pistons. Oil does not return to the compressor as it should. Moving parts lose oil and get dry. When oil stops flowing, friction and heat go up. Over time, this can burn out the compressor.

You also have a bigger chance of dirt getting inside. Metal chips, dirt, and gasket pieces can enter and cause harm. The compressor may break early, and you might lose the whole system. Cooling gets worse, and you may need to buy new parts.

Here is a quick list of what can happen if you skip the accumulator:

Compressor fails more often

More refrigerant leaks

Bad cooling and freeze-ups

Higher chance of compressor burnout

More dirt and moisture in the system

You should check your accumulator every time you do maintenance. Look for rust, leaks, or clogs. If you see oil or refrigerant around it, there may be a leak. Listen for strange sounds and check for musty smells. Use a pressure gauge to see if pressure is too high.

If you find any of these problems, change the accumulator right away. Do not wait until it fails completely. A new accumulator keeps your compressor safe and your system working well. Always use the right size and type for your system. Checking and replacing the accumulator on time saves money and keeps your compressor safe.

Note: A good accumulator helps your compressor last longer and break down less.

Accumulators help stop damage to your rotary compressor. They also help your system work well every day. When you use and take care of them, your compressor is more reliable. You get better efficiency and have fewer times when things break.

Tip: Look at your accumulator often. Change it if you notice any problems.

If you are not sure what to do, ask an expert to check your system. Act now to keep your compressor safe and make your equipment last longer.

An accumulator stops liquid refrigerant from getting into the compressor. It holds extra liquid and lets only vapor move on. This helps stop damage and keeps your compressor working well.

Check your accumulator every time you do regular maintenance. Look for leaks, rust, or anything blocking it. If you see damage or your system is not working right, replace the accumulator.

You should never use a rotary compressor without an accumulator. Without it, liquid refrigerant can get inside and break the compressor. Your system will break down more and cost more to fix.

You might notice weak cooling, strange sounds, or bad smells. High pressure or leaks are also signs of trouble. If you see these things, check your accumulator as soon as you can.

Yes, an accumulator helps send oil back to the compressor. It has a small hole that lets oil move slowly. This keeps parts moving smoothly and helps them last longer.

The accumulator has screens made of fine mesh inside. These screens catch dirt, metal pieces, and other small things. Clean refrigerant goes to the compressor and keeps it safe from harm.

Phase separation keeps liquid and vapor apart inside the accumulator. Heavy liquid stays at the bottom, and vapor rises up. Only vapor goes to the compressor, which stops liquid slugging and helps the system work better.

If you do not take care of the accumulator, your system may leak or cool badly. The compressor could even stop working. You might have to pay more for repairs and wait longer for fixes. Checking the accumulator often keeps your system safe and running well.

No products found