Call Us

+86-13185543350

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-07 Origin: Site

A reciprocating compressor is also called a piston compressor. It uses a piston that moves inside a cylinder to squeeze gas. You can find this compressor where tools need strong air. These places include car repair shops, factories, and food plants. The piston goes back and forth. It pulls in air and pushes it into a smaller space. Knowing how a reciprocating compressor works helps you pick the right tool. This is important for jobs that need high pressure and steady work.

A reciprocating compressor uses a piston that moves back and forth. This squeezes air or gas to make it higher pressure. This compressor is good for jobs that need strong, steady air pressure. It does not give a lot of air flow. The main parts are the piston, cylinder, crankshaft, valves, and housing. Each part is important for how it works. There are single-acting and double-acting types. Double-acting types give more air but need more care. Oil-lubricated compressors last longer but need more upkeep. Oil-free types give clean air for special jobs. Air-cooled compressors are easier to take care of. Water-cooled ones work better in small spaces. Reciprocating compressors are used in car shops, factories, oil and gas, and HVAC systems. They are used because they can do many things. They are simple and do not cost a lot. They are good for jobs that do not run all the time. But they can be loud, shake, and need regular care.

Some people call a reciprocating compressor a piston compressor or a positive displacement compressor. This machine has a piston that moves back and forth inside a cylinder. When you turn it on, the piston pulls in air. Then it squeezes the air into a smaller space. This makes the pressure go up. You can use a reciprocating compressor for many things. It can power air tools or fill tires.

Here is a table that shows how a reciprocating compressor is different from other types:

Characteristic | Description |

|---|---|

Compression Mechanism | Uses pistons inside cylinders to squeeze air (positive displacement) |

Size and Weight | Smaller and lighter than many other compressor types |

Complexity and Cost | Not as complex and costs less |

Application | Good for homes, workshops, and small business projects |

Stages | Comes in single- or multi-stage for different pressure needs |

Reliability and Service Life | Strong and lasts a long time because of tough build |

Installation and Maintenance | Simple to set up and easy to take care of |

Cooling and Lubrication | Can use air or water to cool, and may need oil or not |

Capacity Limitations | Not the best for very big or super high-pressure jobs |

Comparison to Other Types | Squeezes air with pistons, not spinning parts like centrifugal compressors |

Configurations | Can be single-acting or double-acting |

A reciprocating compressor works using the positive displacement principle. This means it traps a set amount of air in a chamber. The piston moves and makes the space smaller. When the space gets smaller, the air pressure goes up. You get steady air at high pressure. This way, you can use the compressor for jobs that need strong, steady air, even if it runs slowly.

If you need more pressure, you can use a multi-stage reciprocating compressor. In this type, air goes through more than one cylinder. Each cylinder squeezes the air more. This helps the compressor reach higher pressures without wasting energy.

Tip: The positive displacement principle lets you control pressure and flow. This makes reciprocating compressors a good pick for jobs that need steady, high-pressure air.

Every reciprocating compressor has important parts inside. Each part does a special job. Here are the main parts:

The piston moves up and down in the cylinder. When it goes down, it pulls air in. When it goes up, it pushes and squeezes the air. Pistons are made from strong stuff like aluminum or cast iron. This helps them handle heat and pressure.

The cylinder is where the piston moves. It holds the air while it gets squeezed. The cylinder must be smooth and strong. This helps the piston move easily and keeps air from leaking.

The crankshaft connects to the motor. It changes the spinning of the motor into the piston’s back-and-forth motion. Crankshafts are made from steel or iron to make them strong and last longer.

Valves let air in and out of the cylinder. The suction valve lets air in when the piston goes down. The discharge valve lets air out when the piston goes up. These valves open and close at the right time. This keeps the compressor working well.

The housing, or crankcase, holds the crankshaft and other moving parts. It keeps these parts safe from dust and damage. The housing also helps keep the compressor cool and oiled.

Note: Other important reciprocating compressor parts are connecting rods, bearings, seals, and sometimes a cooling system. Each part helps the compressor work well and last longer.

Understanding how does a reciprocating compressor work helps you see why it is so useful for many jobs. The process follows a repeating cycle that uses the piston, valves, and crankshaft to move and squeeze air or gas. Let’s break down each part of the cycle and see how the machine operates step by step.

The compression cycle has three main strokes. Each stroke plays a special role in moving and compressing the gas.

During the suction stroke, the piston moves down inside the cylinder. This movement creates a low-pressure area. The suction valve opens, and air or gas flows into the cylinder. You can think of this step as the compressor “breathing in” fresh air.

Next comes the compression stroke. The piston moves up, making the space inside the cylinder smaller. The suction valve closes, trapping the gas inside. As the piston rises, it squeezes the gas, raising its pressure. This is the main step where the compressor does its job.

In the discharge stroke, the piston reaches the top of the cylinder. The discharge valve opens. The high-pressure gas leaves the cylinder and moves into the storage tank or piping system. The cycle then starts again with the next suction stroke.

You can follow these steps to see how does a reciprocating compressor work from start to finish:

Start the compressor with bypass valves open. This lets the machine run at zero load, so it does not build pressure right away.

Slowly load the cylinder chambers in steps, such as 0%, 25%, 50%, 75%, and 100%. You do this by turning on unloaders in a set order. This keeps the machine stable.

During startup, solenoid valves on the unloaders switch after set time intervals. This prevents the suction valve from getting too hot.

After the motor starts, you adjust the bypass valves by hand. Close them slowly to control the suction and discharge pressures. This avoids sudden jumps in pressure.

If you need to control the compressor’s capacity, you can unload cylinders and adjust bypass valves in 25% steps. This helps match the output to your needs.

Always keep a minimum load on each stage, often 25% or 50%. This keeps the machine stable and avoids too much bypass flow.

Use bypass and discharge isolating valves to keep the pressure steady between stages during the compression cycle.

The zero-load step is only for starting up or shutting down, not for normal use.

You can also improve efficiency by adjusting the speed of the compressor to match how much air you need. Running at the right speed reduces wear and saves energy. In many cases, large pressure jumps are split into several stages. Each stage compresses the gas a bit, then cools it before the next stage. This staged approach lowers the work needed and keeps the compressor from getting too hot.

The amount of gas the compressor moves depends on the clearance volume (the small space left when the piston is at the top) and the compression ratio. If the clearance is too big or the compression ratio is too high, the compressor cannot take in as much fresh gas. Keeping these values in check helps the machine work better and use less power.

Tip: You can get the best performance by keeping the clearance volume small and using the right compression ratio for your job.

A reciprocating compressor does not run smoothly like some other machines. The piston moves back and forth, which creates a pulsating motion. This motion causes pressure waves and vibrations in the pipes and the compressor itself.

Pulsation can cause pressure drops and power losses in the piping. This makes the compressor less efficient.

Vibration and pulsation put stress on the machine’s parts and the pipes. Over time, this can lead to damage or even failure.

You might notice more noise and shaking, especially when the compressor runs at higher loads.

To fix these problems, you can use special bottles or filters that absorb the pulsation energy. These devices help reduce pressure swings and mechanical stress.

Good support for the pipes and careful design can also lower vibration and keep the system safe.

If you use these solutions, you can cut down on maintenance, prevent breakdowns, and make the compressor last longer.

Note: Always check for unusual noise or vibration. These signs can warn you about problems before they get worse.

There are different types of reciprocating compressors. Each type is good for certain jobs. Let’s look at the most common ones.

A single-acting compressor uses one side of the piston to squeeze air. When the piston goes down, it pulls air in. When it goes up, it pushes and squeezes the air out. Only one side of the piston does the work.

Single-acting compressors are found in small shops and garages. They are simple and easy to take care of. You can move them easily because they are light and small. These compressors are good for jobs that do not need air all the time. They can reach up to 125 PSIG in one stage. They can go higher in multi-stage designs.

Here is a quick list of good and bad points:

Aspect | Advantages | Disadvantages |

|---|---|---|

Simplicity | Simple design, easy to use | Not as efficient |

Cost | Cheaper for small jobs | Can be loud |

Maintenance | Easy to take care of | Makes more heat |

Pressure | Good for medium pressure | Not for big tough jobs |

Tip: Pick a single-acting compressor if you want a simple, easy-to-move machine for light work.

A double-acting compressor uses both sides of the piston. When the piston moves one way, it squeezes air on one side. When it moves back, it squeezes air on the other side. This design gives more air each time.

Double-acting compressors are best for factories and places that need lots of air. They are bigger and heavier than single-acting types. You need more space and a strong base for these machines. They can reach higher pressures and work better, especially in multi-stage setups.

Here is a table to compare single-acting and double-acting compressors:

Compressor Type | Advantages | Disadvantages |

|---|---|---|

Single-Acting, Air-Cooled | Small, light, easy to move | Loud, not as efficient |

Simple to fix | Not for big tough jobs | |

Double-Acting, Water-Cooled | Works well, good for high pressure | Needs more space, costs more |

Multi-step controls, good for factories | Needs skilled repair, more shaking |

Note: Double-acting compressors need more care and skilled workers to fix. They last longer and save energy on big jobs.

You can pick oil-lubricated or oil-free compressors. Oil-lubricated compressors use oil to help parts move. Oil cools the machine and helps it last longer. You need to change the oil and filters often. These compressors are good for tough jobs like fixing cars or building things.

Oil-free compressors do not use oil in the compression chamber. They use special coatings or materials to stop rubbing. You do not have to worry about oil in the air. Oil-free compressors are great for jobs where clean air is important, like food, medicine, and electronics.

Here is a table to help you compare:

Aspect | Oil-Lubricated Compressors | Oil-Free Compressors |

|---|---|---|

Maintenance | Needs oil changes and filter checks | Less work, but may break more |

Durability | Lasts longer, good for hard jobs | Shorter life, best for clean air |

Air Quality | May need extra filters for clean air | No oil in air, safe for sensitive jobs |

Cost | Cheaper at first | Costs more at first |

Oil-free compressors are best where air touches food, medicine, or electronics.

Oil-lubricated compressors are good for jobs where clean air is not needed.

Tip: Choose oil-free if you need clean air. Pick oil-lubricated for tough, dirty work.

When you look at different reciprocating compressors, you will see air-cooled and water-cooled types. Each one cools itself in a different way. Air-cooled compressors use fans or radiators. These blow air over the machine to move heat away. Water-cooled compressors use water that flows through a heat exchanger. The water takes heat from the compressor and carries it away.

Here is a table to help you compare these two types:

Aspect | Air-Cooled Compressors | Water-Cooled Compressors |

|---|---|---|

Cooling Method | Uses air and fan/radiator to remove heat | Uses water with a heat exchanger |

Energy Efficiency | Needs more power for cooling | Slightly better efficiency |

Operational Costs | Lower setup and maintenance | Extra costs for water, treatment, and cooling tower |

Installation Space | Needs good airflow and space | Works well in tight or harsh spaces |

Water Requirements | None | Needs clean water, often in a closed system |

Heat Recovery Potential | Heated air can warm rooms or power heat exchangers | Heated water can preheat boilers |

Suitability Factors | Best with good ventilation and space | Best where water is easy to get and treat |

Maintenance Complexity | Easier to maintain | More complex due to water system |

You might pick an air-cooled compressor if you want easy setup and less work. This type works best where there is lots of space and good airflow. Water-cooled compressors are better for factories or places with little space and steady water. These machines can run more efficiently, but you must take care of the water and do extra work.

Tip: If you want to save on energy and water, air-cooled compressors are often a smart choice. If you need better efficiency and have water, water-cooled compressors can be a good pick.

The number of stages in a reciprocating compressor changes how much pressure you get and how well it works. You will see single-stage, two-stage, and multi-stage compressors.

Single-Stage Compressors:

In a single-stage compressor, the piston squeezes air in one step. The air goes from the intake right to the storage tank. This type is good for jobs that need low or medium pressure, like filling tires or using small tools. It is simple and easy to fix, but it cannot make very high pressure.

Two-Stage Compressors:

A two-stage compressor uses two pistons and two cylinders. The first piston squeezes the air partway. The air then goes through a cooler before it enters the second cylinder. There, it gets squeezed again. This setup lets you get higher pressure and saves energy. The cooling step between stages makes the air cooler and takes out water. This helps the compressor last longer.

Multi-Stage Compressors:

Multi-stage compressors have more than two stages. Each stage squeezes the air a bit more, with cooling between each step. This design lets you get very high pressure, sometimes up to 7000 PSI. Multi-stage compressors are best for big factories, labs, or places that need clean, dry, high-pressure air. The extra stages mean each piston does less work, so the machine lasts longer.

When you add more stages, you split the work into smaller steps. This makes the compressor work better and last longer. You also get cleaner air because the cooling between stages takes out heat and water.

Note: If you need high pressure and want your compressor to last, pick a two-stage or multi-stage model. For simple jobs, a single-stage compressor is enough.

You can find a reciprocating air compressor in many factories. These machines help run tools that need strong air. You might see them in:

Auto body shops

Tire shops

Woodworking shops

Construction sites

Amusement parks

Industrial plants

In these places, the compressor gives enough pressure for painting or sanding. It also helps with cutting and running machines. These compressors work well for jobs needing quick bursts of air or steady flow. Many factories pick this type because it is easy to care for. It also works for many different tasks.

Tip: If you work in a busy shop, this compressor keeps your tools working all day.

If you work in a car shop, you know compressed air is important. A reciprocating air compressor powers impact wrenches and spray guns. It also runs tire inflators. You can use it to clean parts or paint cars. It helps with fixing engines too.

Here are some reasons to pick this compressor for your shop:

Gives strong air for hard jobs

Handles different tools and air needs

Easy to buy and set up

Good for small or big garages

These compressors fit the stop-and-go work in most shops. They do not need to run all the time. This saves energy and makes them last longer. Spare parts are easy to get. You can fix most problems fast. This makes them a smart pick for any car shop.

In oil and gas work, you need machines for tough jobs. A reciprocating air compressor is very important here. It helps move and process gases at many steps.

Some main uses are:

Gas lift: You put compressed air or gas in oil wells to help bring oil up.

Gas gathering: You move gas from wells to plants, even if the pipe pressure drops.

Gas processing: You squeeze natural gas so you can clean and separate it.

A reciprocating air compressor uses pistons to squeeze gas into a smaller space. This raises the pressure. It helps move gas in pipes, store it, or get it ready to ship. These compressors work at many pressures and flows. This makes them key for oil and gas jobs.

Note: In refineries, these compressors also handle hydrogen and other gases. This helps take sulfur out of oil and makes cleaner fuel.

You can see that reciprocating piston compressors are used in many fields. They give steady air, so they are a top pick for simple and hard jobs.

You can find a reciprocating air compressor in many cooling and heating systems. This compressor is important for keeping your house or work cool or warm. When you turn on your AC or fridge, the compressor starts right away. It pulls in refrigerant gas and squeezes it with a piston moving inside a cylinder. This makes the gas hotter and raises its pressure. The refrigerant is not just air, but it works in a similar way.

The main job of this compressor is to move the refrigerant around the system. When the piston squeezes the gas, it gets hot and high-pressure. The system pushes this gas through coils to let out heat. After that, the refrigerant cools down and becomes a low-pressure gas again. The compressor keeps repeating these steps to keep your space cool or warm.

You will see these compressors in many home appliances. These include fridges, freezers, air conditioners, and water coolers. They are strong and simple, so they last a long time. You do not have to fix them often because they do not break easily. Many people use them for small and medium systems like split ACs and heat pumps.

In HVAC systems, the compressor is in the outside unit. It runs quietly and can handle big pressure changes. A heavy steel shell keeps it safe and helps lower noise. You get good cooling or heating, even when it runs slow.

Here are some reasons to pick a reciprocating air compressor for cooling or heating:

Handles high pressure and heat changes well

Works well at different speeds

Lasts long with little fixing needed

Fits many machines, from home fridges to big coolers

Tip: If you want a quiet system that needs little care, this compressor is a smart pick for cooling or heating.

You can see these compressors in many places where you need to control temperature or humidity. They can make and move compressed air or refrigerant gas, so they are great for homes and businesses.

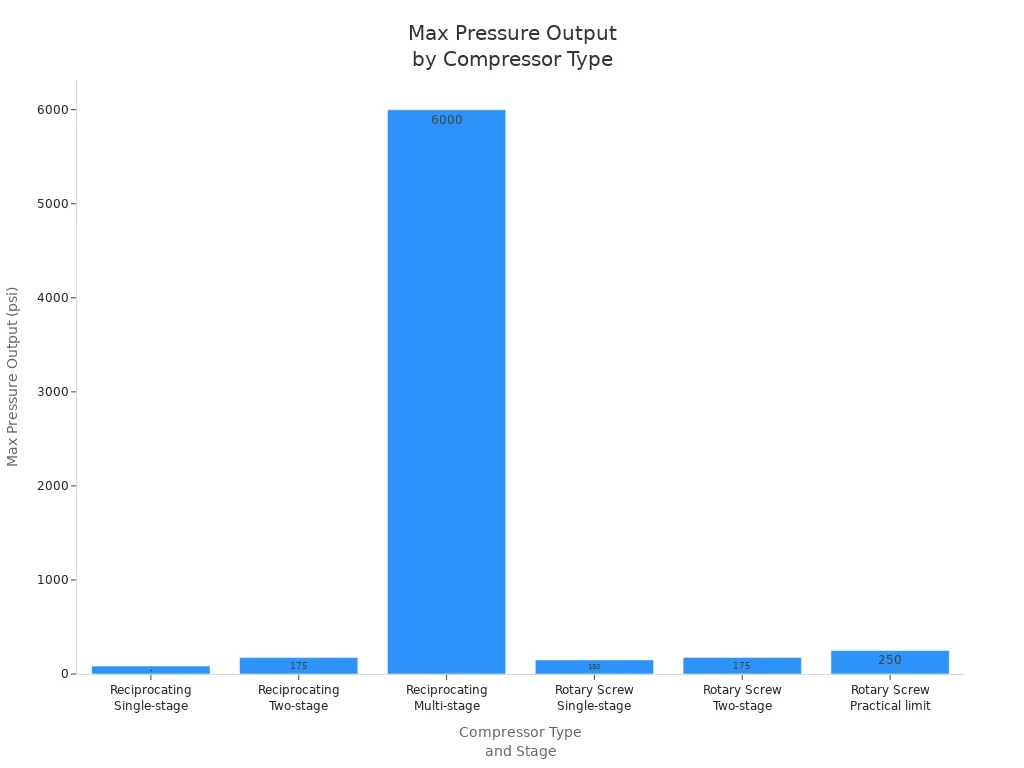

A reciprocating compressor is great when you need strong air. It uses a piston to squeeze air in steps called stages. In one stage, it can make about 120 psi. With two stages, it can reach around 175 psi. Some special models can go up to 6,000 psi or even more. This makes them good for filling gas tanks or using big tools.

Here is a table that shows how much pressure each compressor can make:

Compressor Type | Stage(s) | Typical Maximum Pressure Output (psi) | Notes |

|---|---|---|---|

Reciprocating Compressor | Single-stage | ~85 | Good for small jobs |

Reciprocating Compressor | Two-stage | ~175 | Used in workshops and factories |

Reciprocating Compressor | Multi-stage | Up to 6,000 or more | Needed for very high-pressure applications |

Rotary Screw Compressor | Single-stage | Up to 150 | Used for plant air |

Rotary Screw Compressor | Two-stage | Above 175 | Not common for very high pressure |

Rotary Screw Compressor | Practical limit | About 250 | Not used for extreme pressure |

If you want the most pressure, this compressor gives you more choices than most others.

A reciprocating compressor has a simple design. The piston moves back and forth to squeeze air. This makes it easy to use and fix. You do not need special skills to keep it working. If you only need air sometimes, this machine is a good pick. It can turn on and off without breaking.

Here is a table that compares different compressors:

Compressor Type | Efficiency & Duty Cycle | Heat Generation | Best Use Case | Cost & Maintenance |

|---|---|---|---|---|

Reciprocating | Higher | Intermittent, high-pressure needs | Lower cost, more upkeep | |

Rotary Screw | Higher; 100% duty cycle | Lower | Continuous, changing demand | Higher cost, less upkeep |

Centrifugal | Highest for big, steady jobs | Lower | Large, sensitive industries | Less upkeep, not for high pressure |

You save money because these machines cost less to buy. They are also cheaper to set up. If you do not need air all the time, you do not waste power. This makes them a smart choice for small shops and businesses.

For simple jobs that start and stop, this machine is easy to care for and saves money.

You can use a reciprocating compressor in many places. It works well in small shops, car garages, and outside. Dust or dirt does not hurt it much. The design is tough and can handle rough spots. You only turn it on when you need air. This saves energy and helps it last longer.

You can use it for painting, filling tires, or running tools.

It fits in tight spaces and does not need a special room.

You can move it from place to place.

It works in hot, cold, or dirty areas.

You also spend less money at first. It costs 20-50% less than rotary types. You do not need fancy tools to fix it. If you need more pressure, you can get a multi-stage model. This lets you use one machine for many jobs.

You get a tool that works for many things, from home jobs to hard factory work.

Reciprocating compressors can be very loud. The piston moves fast inside the cylinder. This makes a lot of noise. Most models make sounds from 40 to 92 decibels. If you work near a machine louder than 85 decibels for a long time, your hearing can get hurt. Loud places can also make you feel stressed and tired. It is harder to focus when it is noisy. Vibration is also a problem. The shaking from the machine can move through pipes and walls. This makes the noise even worse.

Here are some ways noise and vibration can affect you at work:

You can lose hearing if you do not wear earplugs.

You may feel more stress and get tired faster.

It is hard to pay attention and get work done.

You might not hear alarms or warnings, which is unsafe.

You can fix these problems with sound barriers, foam, or pads. Putting the machine in a box or using silencers helps too. Good setup and regular checks keep noise and shaking down.

Tip: Always use ear protection and look for loose parts if you hear more noise or feel more shaking.

You need to take care of a reciprocating compressor to keep it working. These machines need to be checked and cleaned often. If you skip this, the machine can break or cost a lot to fix. A good plan helps you stop problems and saves money.

Here is an easy plan for taking care of your compressor:

Every day, look for leaks, odd noises, and drain water from the tank.

Each week, clean the air filter and check hoses and pressure valves.

Once a month, check the belt and change the oil if needed.

Every three months, tighten bolts and put in new oil filters.

Twice a year, clean the crankcase and check the valves.

Doing these things keeps your machine running well. It also saves energy because leaks and old parts waste power. If you follow these steps, you will stop most big problems and keep your air system working.

Note: If you skip maintenance, you will have more breakdowns and spend more money later.

Reciprocating compressors are bigger than some other types. They are heavy, especially if you need more power. You need more space to put one in your shop or factory. Moving these machines is hard because they weigh more than rotary models. If you want a small or easy-to-move machine, this can be tough.

Here is a table that shows how different compressors compare in size and weight:

Compressor Type | Power Output (hp) | Weight Range (lbs) | Typical Tank Size (gal) | Size/Weight Notes |

|---|---|---|---|---|

Reciprocating | 0.7 to 15 | 108 to 1,510 | 13 to 80 | Bigger, needs more room |

Rotary Screw | 3 to 40 | 276 to 1,700 | 53 to 120 | Smaller, easier to move and set up |

Centrifugal | N/A | Much larger | N/A | Heaviest, used in big factories |

If you need air in a small space or want to move your machine a lot, a rotary model is easier. Reciprocating compressors are best if you have lots of space and do not need to move them.

Note: Always check your space before you buy a new machine so you do not have problems setting it up.

Reciprocating and rotary compressors work in different ways. Reciprocating compressors have a piston that moves up and down. Rotary compressors use two rotors that spin and trap air. The spinning rotors squeeze the air smoothly and steadily.

Here is a table that shows how they are different:

Feature | Reciprocating Compressor | Rotary Compressor |

|---|---|---|

Mechanism | Piston, cylinder, crankshaft | Two meshing helical screws (rotors) |

Motion | Piston moves up and down | Rotors spin continuously |

Compression Process | Vacuum and pressure cycles | Continuous air volume reduction |

Airflow | Intermittent flow | Smooth, continuous flow |

Compression Cycle | Cyclic with intake/discharge valves | Continuous with inlet/outlet valves |

Lubrication | Not always needed | Oil used for cooling and sealing |

Rotary compressors give a steady flow of air. They are quieter and shake less because the rotors move smoothly. Reciprocating compressors are louder and shake more because of the piston’s motion. Rotary compressors are better for jobs that run all day. You often see them in big factories or places that need lots of air.

Centrifugal compressors use a spinning part called an impeller. The impeller throws air outward very fast. The air slows down in a diffuser, which raises its pressure. These compressors do not use pistons or rotors. The whole process is quick and smooth.

Here is a table to compare centrifugal and reciprocating compressors:

Aspect | Reciprocating Compressors | Centrifugal Compressors |

|---|---|---|

Compression Type | Positive displacement (piston and cylinder) | Dynamic (rotating impellers and diffusers) |

Flow Capacity | Low flow, limited by cylinder size and speed | Medium to high flow, handles very large volumes |

Pressure Ratio | High-pressure ratio applications | Medium to high pressure, aerodynamic limits |

Efficiency | Lower, varies with gas and ratio | Higher (70-85%, up to ~90%), less loss |

Operating Costs | Higher, more wearing parts | Lower, fewer wearing parts |

Noise and Vibration | More pulsation and noise | Smoother, less vibration and noise |

Application Suitability | High-pressure, low-flow, variable gases | Large-scale, continuous, carbon capture, big industries |

Size and Complexity | Bulkier, simple parts | More compact, complex parts |

Centrifugal compressors are best when you need to move a lot of air. They run quietly and need less fixing. You find them in big plants or places that run all day.

- Reciprocating compressors use pistons and cylinders for high pressure and low flow.

Centrifugal compressors use spinning impellers for high flow and steady work.

Centrifugal types are smaller, need less care, and make less noise.

Think about your job before picking a compressor. Each type is good for different needs. Here are some things to think about:

Factor | Reciprocating Compressor | Rotary Screw Compressor |

|---|---|---|

Application Suitability | Intermittent use, small shops, tough places | Continuous use, big factories, clean air |

Duty Cycle | 20-30%, needs rest | 100%, runs nonstop |

Maintenance | More often, easy to do | Less often, needs skill |

Initial Cost | Lower | Higher |

Lifetime Cost | Higher energy and upkeep | Lower energy, lasts longer |

Reliability | More strain, better in dirt | Smoother, more reliable |

Noise Level | Louder | Quieter |

Size and Space | Bigger, needs more room | Smaller, fits tight spaces |

Operating Environment | Good for outdoors or dirty air | Best indoors, needs clean air |

Air Storage | Needs a tank | May not need a tank |

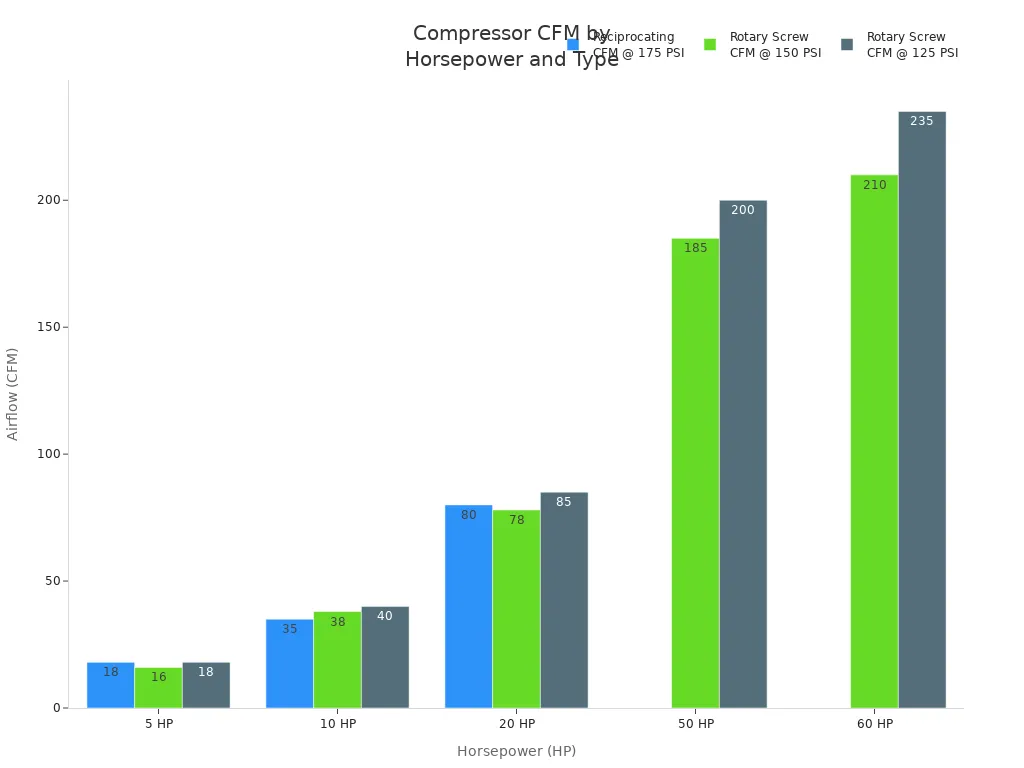

Rotary screw compressors give more air for each horsepower. Here is a chart that shows this:

Tip: If you only need air sometimes and work in a rough place, pick a reciprocating compressor. If you need air all day and want less noise, pick a rotary or centrifugal compressor.

You now know a reciprocating compressor uses a piston to press gas and make it higher pressure. This machine is good for jobs that need strong pressure but not much gas flow. It can also work with hard gases like hydrogen. Here are some main things to remember:

Pick this compressor if you need high pressure, work in dirty places, or want something simple and easy to move.

It will be louder and need more care, but it costs less at first and is simple to fix.

Tip: Always pick a compressor that fits your job’s pressure, flow, and how often you use it.

You use a reciprocating compressor to increase the pressure of air or gas. The piston moves inside the cylinder and squeezes the gas into a smaller space. This action raises the pressure so you can use it for tools or machines.

You should check your compressor daily for leaks and odd noises. Clean filters weekly. Change oil and inspect belts monthly. Always follow the maintenance schedule in your manual. Regular care helps your compressor last longer and work better.

You should not run most reciprocating compressors nonstop. These machines work best for short or medium jobs. If you need air all day, a rotary screw compressor fits better. Running a reciprocating compressor too long can cause overheating.

You should use non-detergent compressor oil. This oil protects moving parts and helps reduce wear. Always check your manual for the right oil type and grade. Using the wrong oil can damage your compressor.

The piston moves quickly inside the cylinder. This motion creates noise and vibration. If you hear more noise than usual, check for loose parts or worn components. Using pads or sound covers can help reduce the noise.

If you skip maintenance, your compressor can break down. You may see leaks, low pressure, or overheating. Repairs can cost more than regular care. Always follow a maintenance plan to keep your machine running safely.

Yes, you can use an oil-free reciprocating compressor for clean air jobs. These models do not add oil to the air. They work well in food, medical, or electronics industries where you need pure air.

First, list all the tools you want to use. Check the air pressure (PSI) and flow (CFM) each tool needs. Pick a compressor that meets or exceeds these numbers. Always add a safety margin for best results.

No products found